High-coercivity rare-earth-free MnAlM permanent magnet alloy and preparation method thereof

A technology of permanent magnet alloy and high coercive force, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., and can solve problems such as low coercive force, high saturation magnetization and high coercive force that are difficult to obtain at the same time problem, to achieve the effect of increasing the coercive force of the alloy, facilitating production and promotion, and reducing intergranular exchange coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Ingredients

[0047] The pure manganese block, pure aluminum block and pure tungsten powder with a purity of not less than 99.9% are used according to the nominal molecular formula Mn 50 al 49 W 1 Raw materials are prepared to obtain master alloy raw materials. In addition, based on the mass of Mn in the master alloy raw materials, an additional 3% pure manganese block is added to the master alloy raw materials.

[0048] (2) Preparation of MnAlM alloy ingot

[0049] Using a non-consumable vacuum electric arc furnace, put the master alloy raw material into a water-cooled copper crucible, and fill it with an inert gas (argon) as a protective gas after vacuuming, repeat the above pumping and filling process 3 times, and put it under an inert gas atmosphere. The alloy is repeatedly smelted 3 times, and the surface is turned over every time it is smelted. The vacuum degree of the vacuum electric arc furnace is higher than 1*10 -3 Pa, the current intensity of the vacu...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is: the nominal molecular formula Mn of high coercive force rare earth-free MnAlM permanent magnet alloy 50 al 48 W 2 , the current intensity of the vacuum electric arc furnace is 55A, smelting 4 times, the heat treatment temperature is 1200 ℃, the heat treatment time is 18h, and the rest is exactly the same as in Example 1.

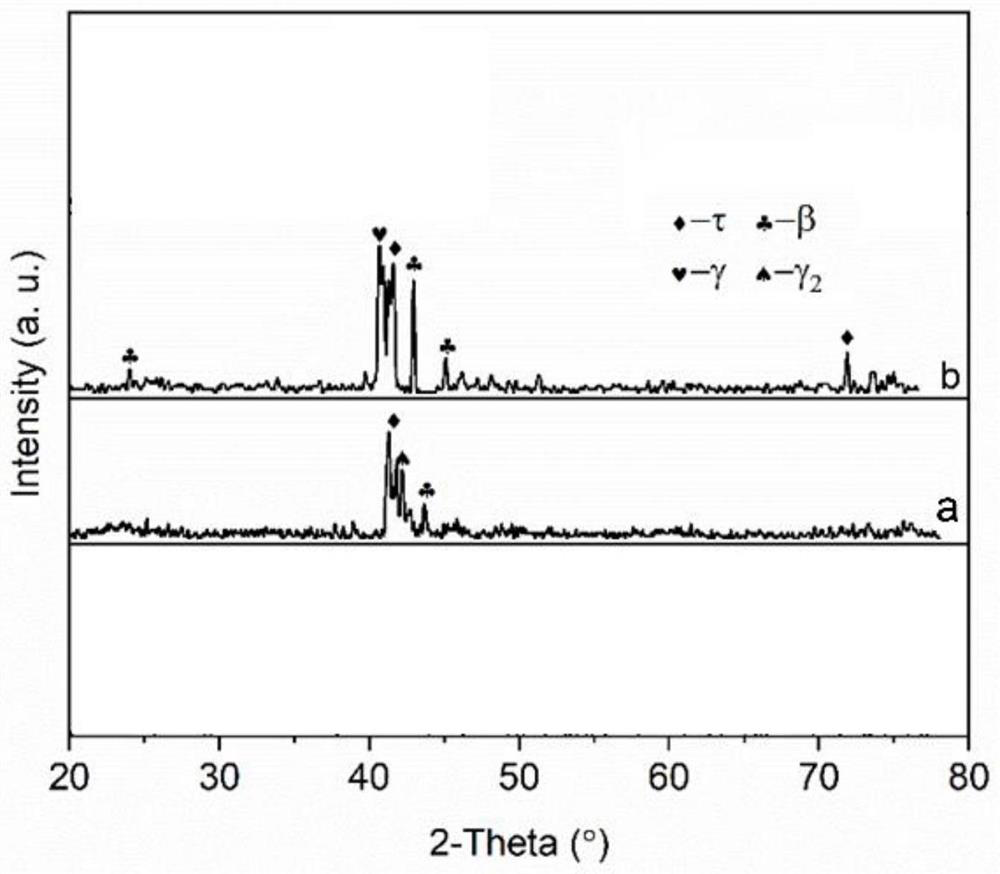

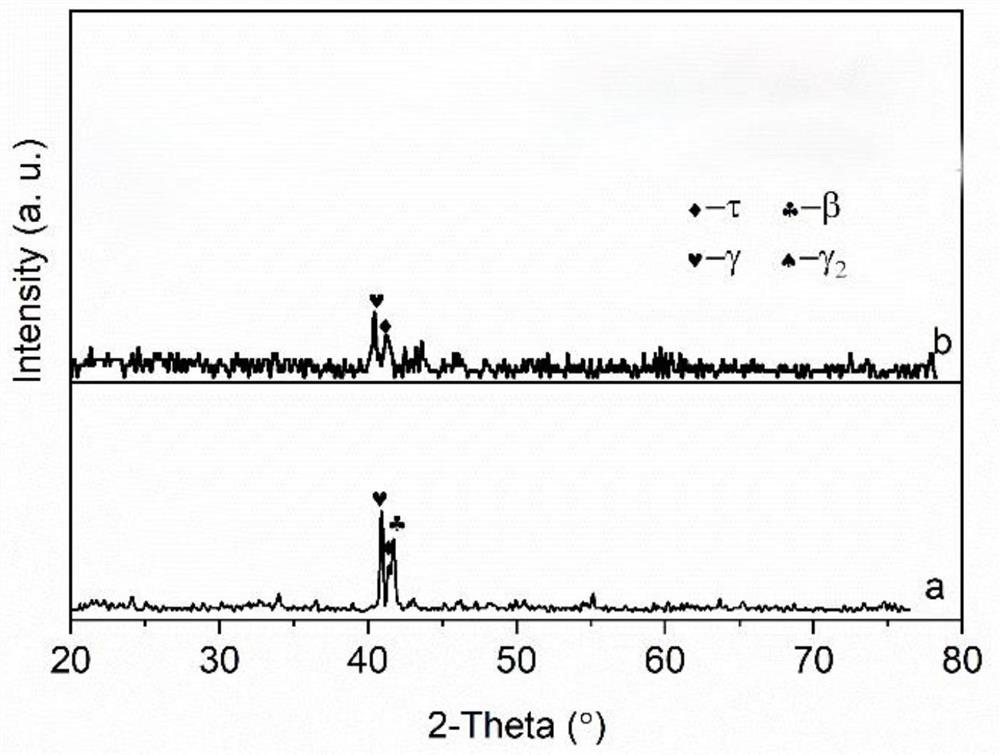

[0057] mn 50 al 48 W 2 The XRD pattern of the alloy ingot is as follows figure 1 Shown in curve (b).

[0058] mn 50 al 48 W 2 The magnetic performance data of permanent magnet alloy ingots under different temperature conditions are shown in Table 1.

[0059] High coercive force Rare earth free Mn 50 al 48 W 2 The XRD pattern of the permanent magnet alloy ingot is as follows figure 2 Shown in curve (b).

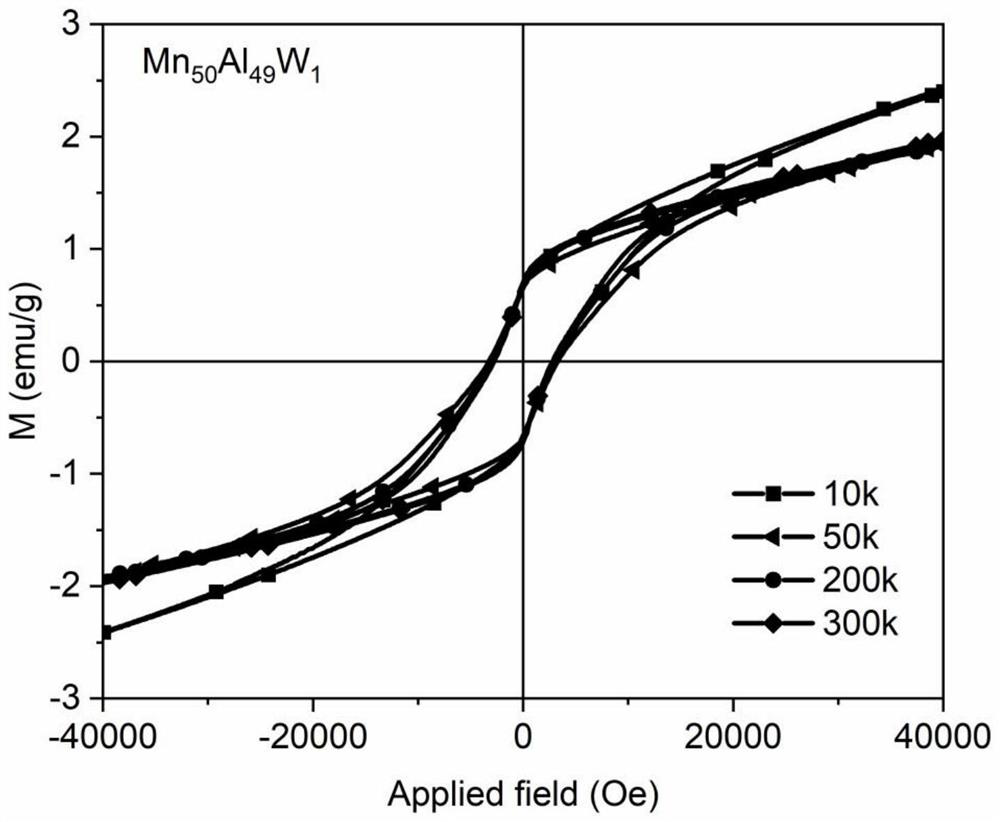

[0060] High coercive force Rare earth free Mn 50 al 48 W 2 The hysteresis loops of permanent magnet alloy ingots measured under different temperature conditions are as follows:...

Embodiment 3

[0067] Compared with embodiment 1, embodiment 3 is different in that: the pure manganese block, pure aluminum block and pure zinc block with a purity of not less than 99.9% are used according to the nominal molecular formula Mn of the high coercive force rare earth-free MnAlM permanent magnet alloy 50 al 49 Zn 1 Raw materials were configured to obtain master alloy raw materials, and the rest were identical to Example 1.

[0068] mn 50 al 49 Zn 1 The XRD pattern of the alloy ingot is as follows Figure 7 Shown in curve (a).

[0069] High coercive force Rare earth free Mn 50 al 49 Zn1 The magnetic performance data of permanent magnet alloy ingots under different temperature conditions are shown in Table 2.

[0070] High coercive force Rare earth free Mn 50 al 49 Zn 1 The XRD pattern of the permanent magnet alloy ingot is as follows Figure 8 Shown in curve (a).

[0071] High coercive force Rare earth free Mn 50 al 49 Zn 1 The hysteresis loops of permanent magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com