System and method for coupling optical fiber image transmitting element with photosensitive surface in image sensor

An image sensor and optical fiber image transmission technology, which is applied in electrical components, image communication, components of TV systems, etc., can solve the problems of high coupling cost, easy occurrence of micro-displacement, and difficult monitoring of coupling effect, so as to avoid surface pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The coupled sample is a fiber optic cone and a CCD camera.

[0101] The fiber optic cone specifications are: diameter of the big end is 49mm, effective diameter is 44.6mm; diameter of the small end is 20×11mm, effective size is 19.5×10.8mm, magnification ratio is 2:1, and the diameter of the elemental filament is 6μm (big end).

[0102] The photosensitive surface of the CCD camera is 19.5×10.8mm, and the pixel size is 10×10μm.

[0103] The photosensitive surface of the chip is at the lower part of the output surface of the optical fiber cone.

[0104] Coupling Photosensitive Adhesive: Refractive Index n D 1.55; colorless and transparent; bonding strength >90Kg / cm 2 ;Visible transmittance>90%.

[0105] Light curing wavelength: ~320nm; Light curing time: 5-10s;

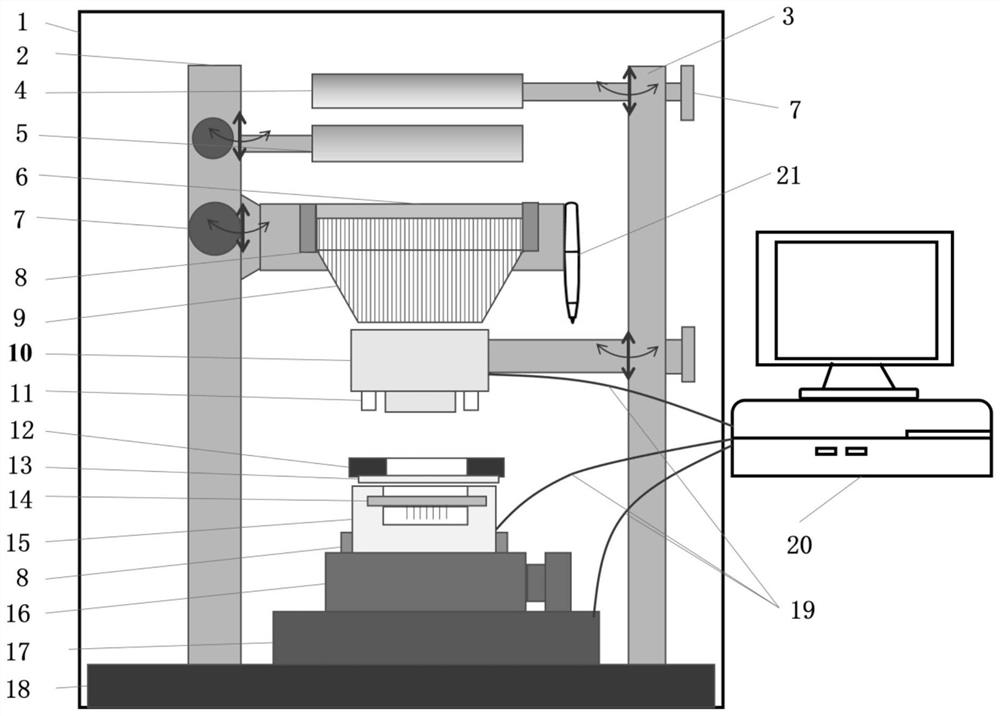

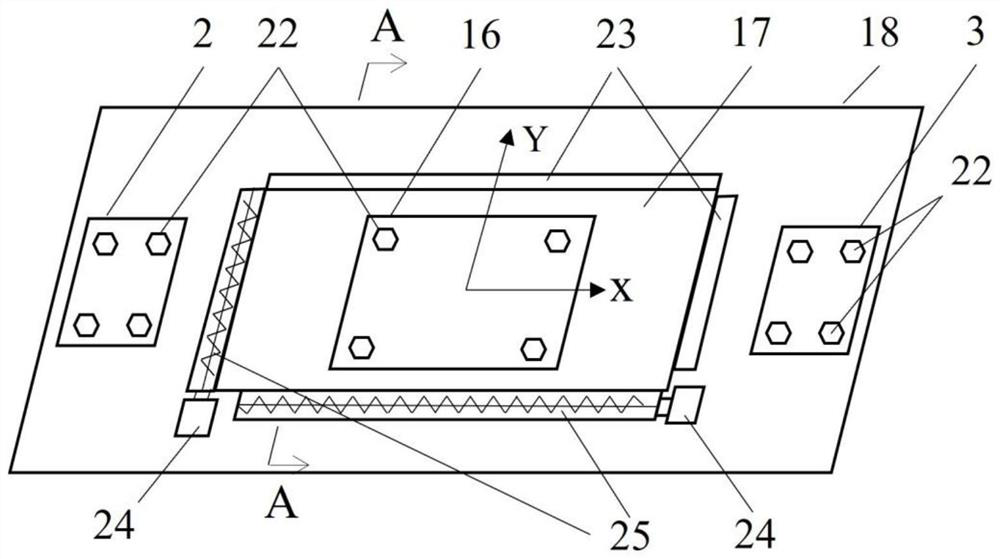

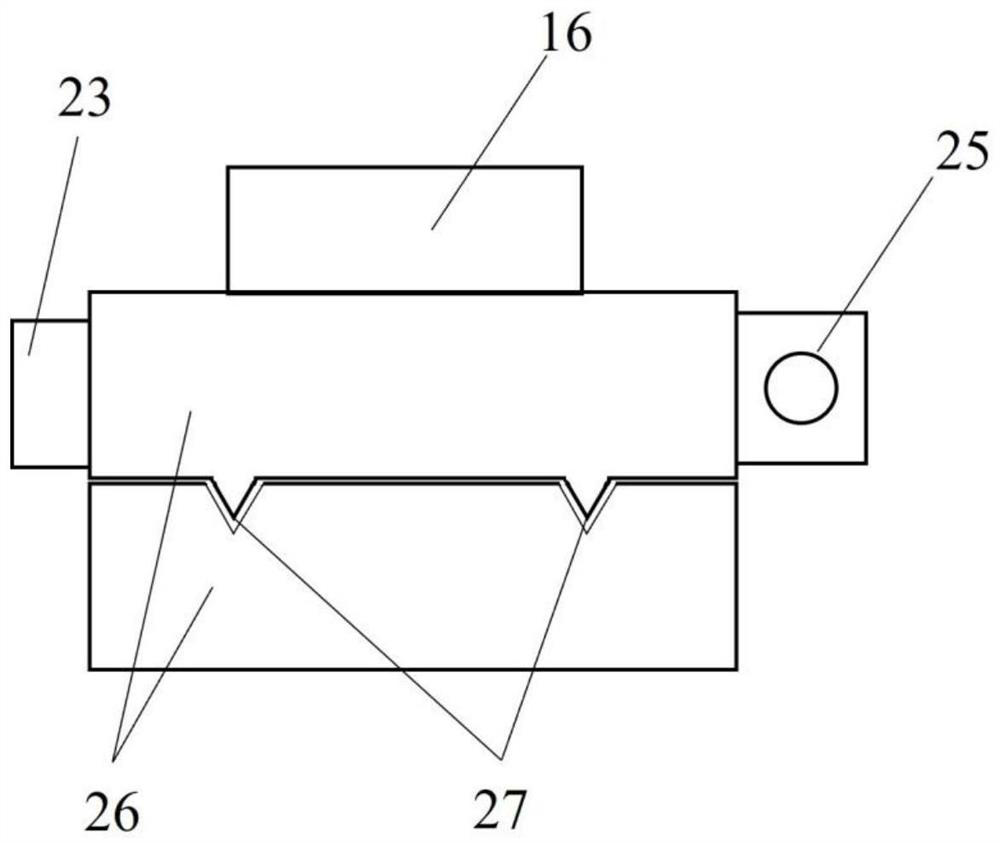

[0106] The system for coupling the optical fiber image transmission element and the photosensitive surface in the image sensor of this embodiment includes:

[0107] The main structure unit comprises a shadin...

Embodiment 2

[0122] Couple the sample to a fiber optic panel and a CMOS camera.

[0123] The specifications of the fiber optic panel are: outer diameter 21.85mm, effective diameter 18.3mm; unit wire diameter 6μm.

[0124] The pixel size of the CMOS camera chip is 5.5×5.5μm, and the area size of the photosensitive surface is 12.7×9.6mm.

[0125] The photosensitive surface of the chip is inside the light-transmitting surface of the fiber optic panel.

[0126] Coupling Photosensitive Adhesive: Refractive Index n D 1.7; 500-550nm average light transmittance > 98%; bonding strength > 70Kg / cm 2 ;

[0127] Light curing wavelength and time: UV wavelength 320-390nm, curing time: 20-30s;

[0128] The setting and positional relationship of each part of the system are the same as in Embodiment 1.

[0129] Through the above system, not only can the coupling quality be judged in real time, but also the characteristic performance indicators of the whole system can be measured:

[0130] Resolution a...

Embodiment 3

[0138]The coupled samples are an image inverter and a CMOS camera.

[0139] The specifications of the fiber optic inverter are: outer diameter 19mm, effective diameter 16.3mm. Limited by the size of the CMOS chip, the output end of the image inverter is processed into an annular surface of 16×14 mm, and the diameter of the unit wire is 6 μm. Inversion angle: 180°±1°;

[0140] The photosensitive surface of the chip is inside the light-transmitting surface of the fiber optic panel.

[0141] Coupling Photosensitive Adhesive: Refractive Index n D 1.7; 500-550nm average light transmittance > 98%; bonding strength > 70Kg / cm 2 ;

[0142] Light curing wavelength and time: UV wavelength 320-390nm, curing time: 5-10s;

[0143] Except the CMOS camera, all the other are the same as embodiment 1 in the described system. The CMOS camera uses a scientific grade CMOS chip with a pixel size of 6.5×6.5μm, a photosensitive surface area size of 16.6×14.0mm, and 5.5 million pixels.

[0144]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com