Self-cleaning water-based nano coating

A nano-coating and self-cleaning technology, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of not meeting the needs of use, being polluted, and not being able to fully disperse pigments and fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In addition, the present application also provides a preparation method of self-cleaning water-based nano-coating, comprising the following steps:

[0039] Add water-based polyurethane acrylic emulsion, polyamide-imide resin, modified epoxy resin, diatomaceous earth, filler and dispersant to the reaction kettle, and stir at 800r / min-1200r / min for 30min under the first temperature condition -60min, obtain mixture A;

[0040] Add a catalyst, a coupling agent and an anti-corrosion additive to the mixture A, and stir at a speed of 300r / min-500r / min under ultrasonic conditions for 15min-20min to obtain a mixture B;

[0041] Add a curing agent, a defoamer and a rheological agent to the mixture B, and stir at a speed of 1000r / min-1200r / min for 20min-30min under the second temperature condition to obtain a self-cleaning water-based nano coating.

[0042] In one embodiment, the first temperature condition is 45°C-60°C.

[0043] In one embodiment, the ultrasonic conditions are:...

Embodiment 1-3

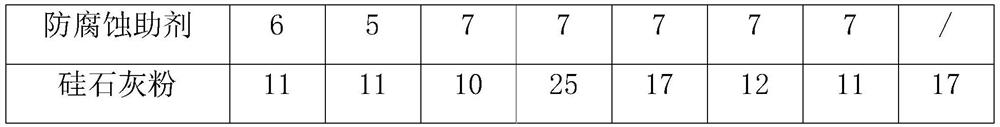

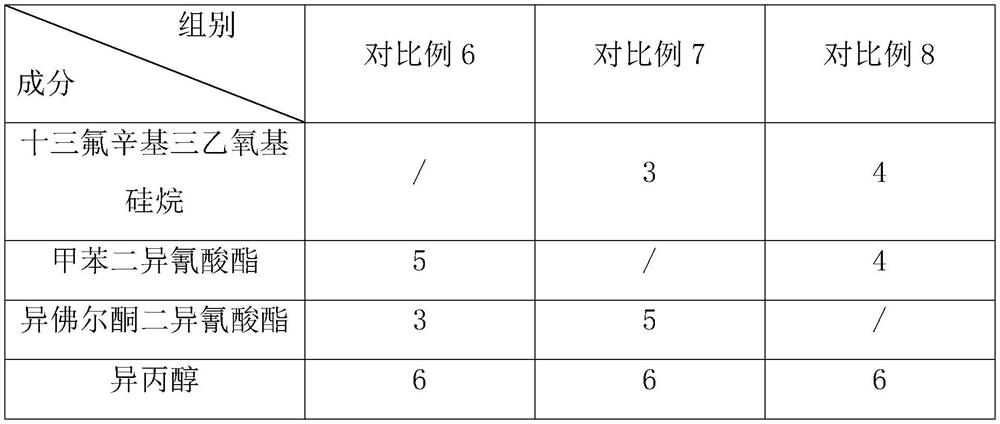

[0048] The preparation raw materials of the self-cleaning water-based nano paint of embodiment 1-3 are as shown in table 1;

[0049] The preparation method of the self-cleaning water-based nano paint of embodiment 1-3 may further comprise the steps:

[0050] Add 3g of tridecafluorooctyltriethoxysilane, 2g of toluene diisocyanate, 3g of isophorone diisocyanate and 6g of isopropanol into the mixing kettle, and mix at a speed of 800r / min-1200r / min for 10min- After 20 minutes, it was used as a coupling agent for later use;

[0051] 80g coconut acid diethanolamide is mixed with 20g3-propanediol, as anti-corrosion auxiliary agent, for subsequent use;

[0052] Add 2g of zinc oxide, 5g of silicon dioxide, 3g of bismethylolpropionic acid, and 6g of calcium carbonate into the ball mill, and ball mill for 20 minutes at a speed of 50r / min-100r / min and a temperature of 45°C-50°C After -40min, it will be used as a dispersant for later use;

[0053] Add water-based polyurethane acrylic em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com