Preparation method of high-purity sodium chromite

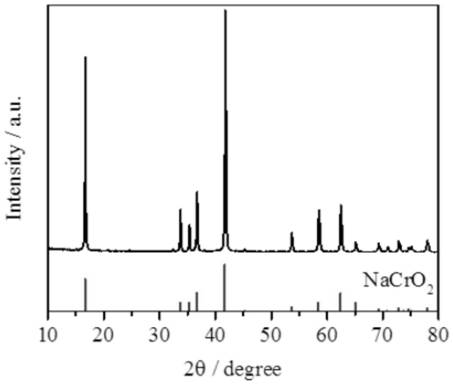

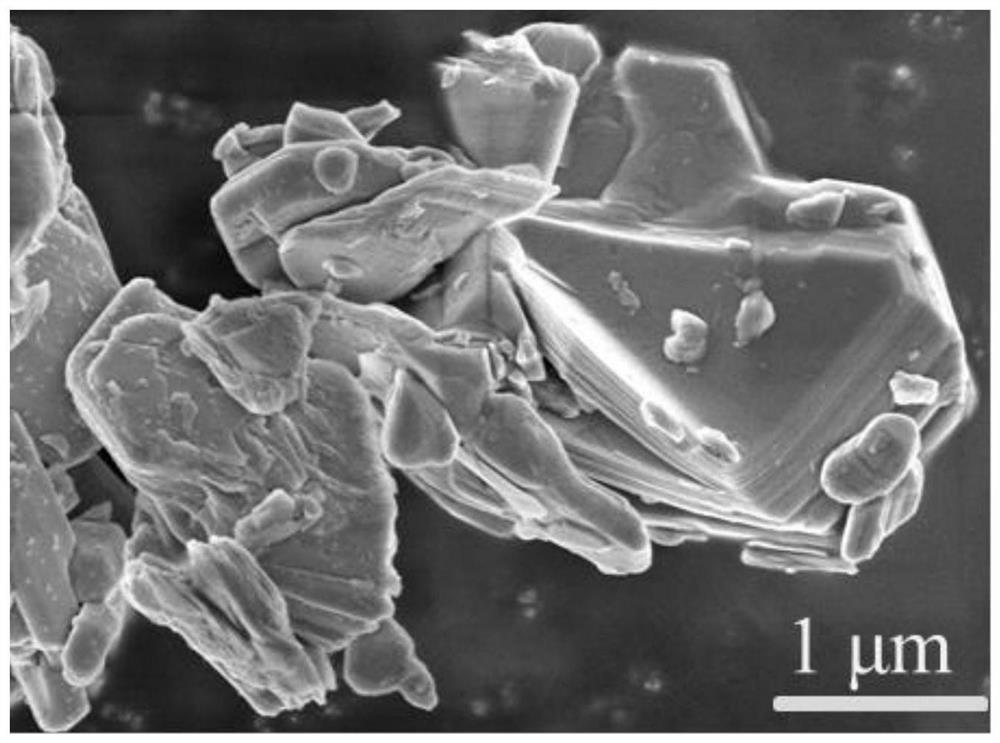

A sodium chromite, high-purity technology, applied in separation methods, chemical instruments and methods, chromium compounds, etc., can solve the influence of sodium chromite on electrochemical performance, low purity of sodium chromite samples, long reaction time, etc. problem, to achieve the effect of fine particle size, good crystal integrity, and complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of high-purity sodium chromite of the present invention comprises the following steps:

[0028] Step 1. Mix chromium oxide and 20% nitric acid solution according to the solid-to-liquid mass ratio of 1:10, stir at room temperature for 2 hours, filter, wash chromium oxide with high-purity water until the washing water is neutral, and dry at 60°C for 4 hours; mix sodium carbonate with high-purity water Mix according to the mass ratio of 2:1, heat to 60°C, stir and add 2mL ferric chloride solution with a concentration of 1mg / mL, keep the temperature at 60°C and let it stand for 10h, filter out the precipitate impurities, and continue to heat the filtrate at 60°C until the filtrate Concentrate, cool and crystallize, centrifuge and dehydrate, detect that the chloride ion content is less than 0.001%, heat to melt and dry at 110°C for 6 hours;

[0029] Step 2. Mix the pretreated chromium oxide and sodium carbonate in a molar ratio of 1:1.2, pulveriz...

Embodiment 2

[0033] A kind of preparation method of high-purity sodium chromite of the present invention comprises the following steps:

[0034] Step 1. Mix chromium oxide and 20% nitric acid solution according to the solid-to-liquid mass ratio of 1:10, stir at room temperature for 2 hours, filter, wash chromium oxide with high-purity water until the washing water is neutral, and dry at 60°C for 4 hours; mix sodium carbonate with high-purity water Mix according to the mass ratio of 2:1, heat to 60°C, stir and add 2mL ferric chloride solution with a concentration of 1mg / mL, keep the temperature at 60°C and let it stand for 10h, filter out the precipitate impurities, and continue to heat the filtrate at 60°C until the filtrate Concentrate, cool and crystallize, centrifuge and dehydrate, detect that the chloride ion content is less than 0.001%, heat to melt and dry at 110°C for 6 hours;

[0035] Step 2, mixing the pretreated chromium oxide and sodium carbonate in a molar ratio of 1:1.1, pulve...

Embodiment 3

[0039] A kind of preparation method of high-purity sodium chromite of the present invention comprises the following steps:

[0040] Step 1. Mix chromium oxide and 20% nitric acid solution according to the solid-to-liquid mass ratio of 1:10, stir at room temperature for 2 hours, filter, wash chromium oxide with high-purity water until the washing water is neutral, and dry at 60°C for 4 hours; mix sodium carbonate with high-purity water Mix according to the mass ratio of 2:1, heat to 60°C, stir and add 2mL ferric chloride solution with a concentration of 1mg / mL, keep the temperature at 60°C and let it stand for 10h, filter out the precipitate impurities, and continue to heat the filtrate at 60°C until the filtrate Concentrate, cool and crystallize, centrifuge and dehydrate, detect that the chloride ion content is less than 0.001%, heat to melt and dry at 110°C for 6 hours;

[0041]Step 2. Mix the pretreated chromium oxide and sodium carbonate in a molar ratio of 1:1, pulverize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com