Ethanol-free composite microemulsion system antibacterial spray and preparation method thereof

A microemulsion and system technology, applied in botany equipment and methods, antibacterial drugs, antifungal agents, etc., can solve the problems of low bioavailability and poor stability, achieve enhanced antibacterial effect, low equipment requirements, and high preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

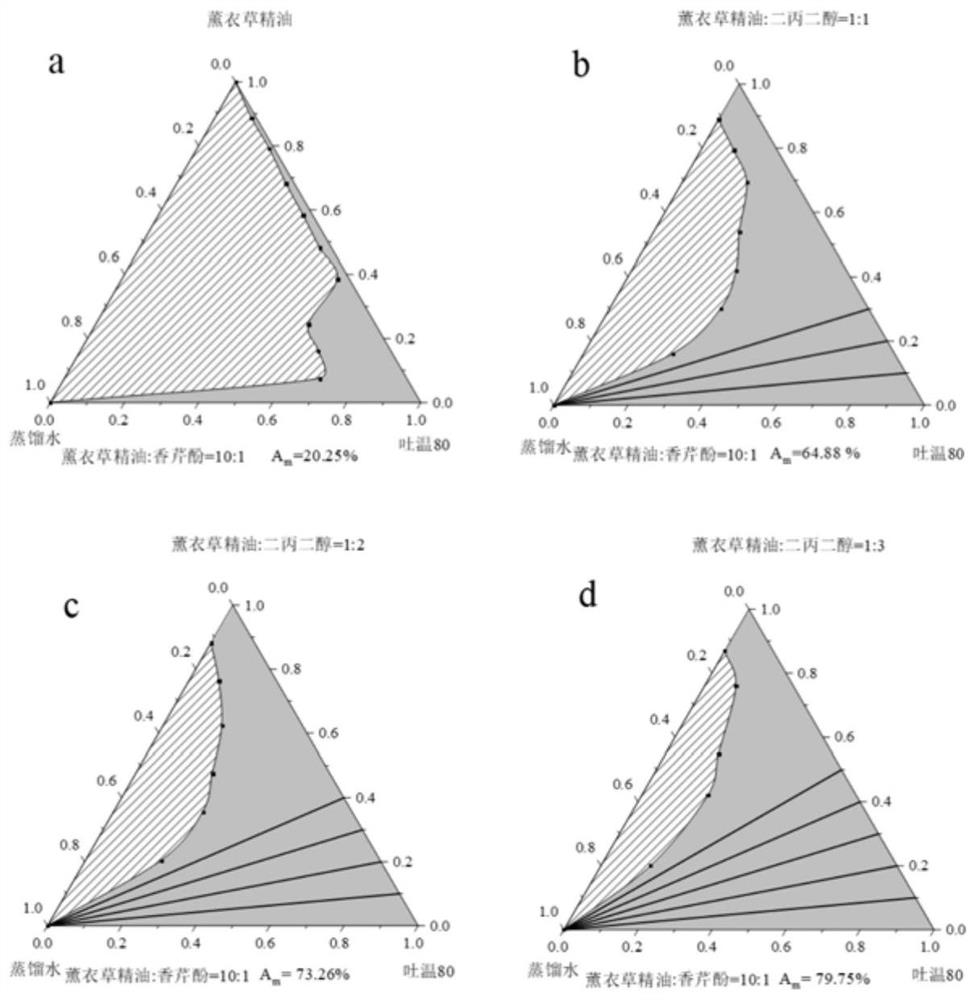

[0032] First mix lavender essential oil with carvacrol at a mass ratio of 10:1, and with citronellol at a mass ratio of 1:1, and then follow the mass ratios of lavender essential oil and cosurfactant dipropylene glycol at 1:0, 1:1, Add dipropylene glycol at 1:2 and 1:3, and finally according to the mass ratio of surfactant to (lavender essential oil / dipropylene glycol): 0:10, 1:9, 2:8, 3:7, 4:6, 5: 5, 6: 4, 7: 3, 8: 2, 9: 1 and 10: 0 to configure a mixed system, shake in a 150rpm water bath at 25°C until uniform, then add distilled water dropwise at intervals of 1 to 3 hours, shake, and the recording system changes from clear to cloudy , and calculate the proportion of each component in the system at the critical point, and draw a pseudo-ternary phase diagram with lavender essential oil / dipropylene glycol, surfactant and water as three vertices respectively. The grid area is the non-microemulsion phase area, the blank gray area is the microemulsion phase area, and the boundary...

Embodiment 2

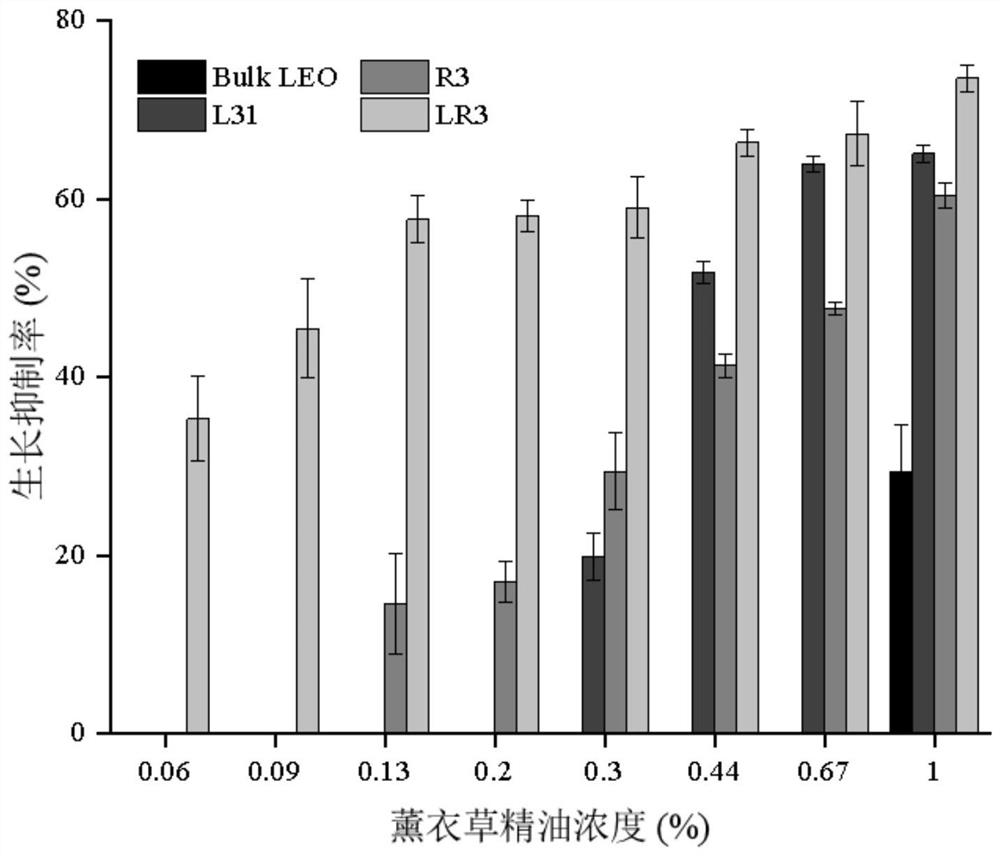

[0035] In the pseudo-ternary phase diagram in which the mass ratio of lavender essential oil and dipropylene glycol is 1:3, choose the infinite dilution line with the smallest dilutable ratio, that is, a wireless dilution line with a relatively small surfactant content in the wireless dilutable line, which is figure 1Point LR3 in the single-phase region. The specific process is as follows: mix lavender essential oil and carvacrol at a mass ratio of 10:1, shake evenly, then add dipropylene glycol according to the mass ratio of lavender essential oil and co-surfactant dipropylene glycol 1:3, continue shaking evenly as the oil phase, Finally, configure the mixed system according to the mass ratio of the oil phase to Tween 80 of 5:5. After shaking in a 150rpm water bath at 25°C until uniform, slowly add distilled water dropwise until the concentration of lavender essential oil is 2%, and the concentration of carvacrol is 0.2%. Fill it into an atmospheric pressure spray bottle. Be...

Embodiment 3

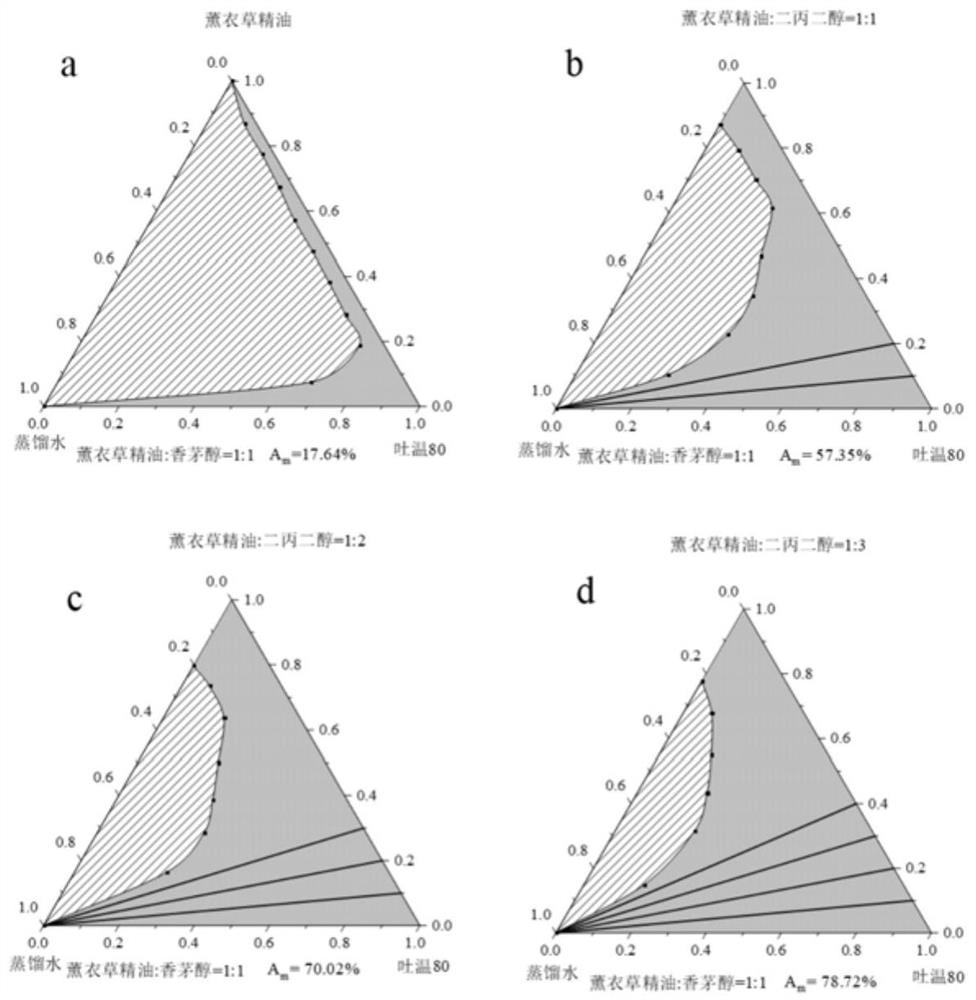

[0037] In the pseudo-ternary phase diagram in which the mass ratio of lavender essential oil and dipropylene glycol is 1:3, choose the infinite dilution line with the smallest dilutable ratio, that is, a wireless dilution line with a relatively small surfactant content in the wireless dilutable line, which is figure 2 Point LT3 in the single-phase region. The specific process is as follows: mix lavender essential oil and citronellol in a mass ratio of 1:1, shake evenly, then add dipropylene glycol according to the mass ratio of lavender essential oil and co-surfactant dipropylene glycol 1:3, continue shaking evenly as the oil phase, Finally, configure the mixed system according to the mass ratio of the oil phase to Tween 80 as 4: 6. After shaking in a 150rpm water bath at 25°C until uniform, slowly add distilled water dropwise until the concentration of lavender essential oil is 2%, and the concentration of citronellol is 2%. Fill it into an atmospheric pressure spray bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com