Preparation method of PBAT/PLA/CaCO3 full-biodegradable composite material

A composite material and all-biological technology, which is applied in the field of preparation of PBAT/PLA/CaCO3 fully biodegradable composite materials, can solve the problems of composite materials such as the decline in mechanical properties, poor interface compatibility, and easy aggregation of inorganic powders to achieve good appearance and Mechanical properties, beneficial to market promotion, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

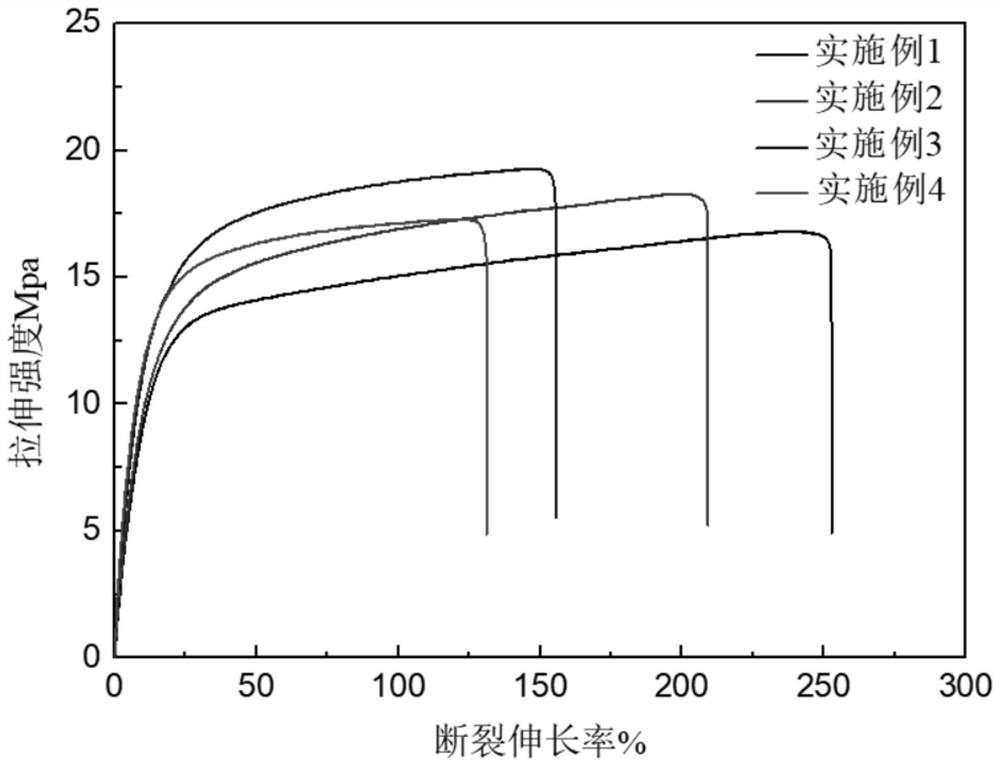

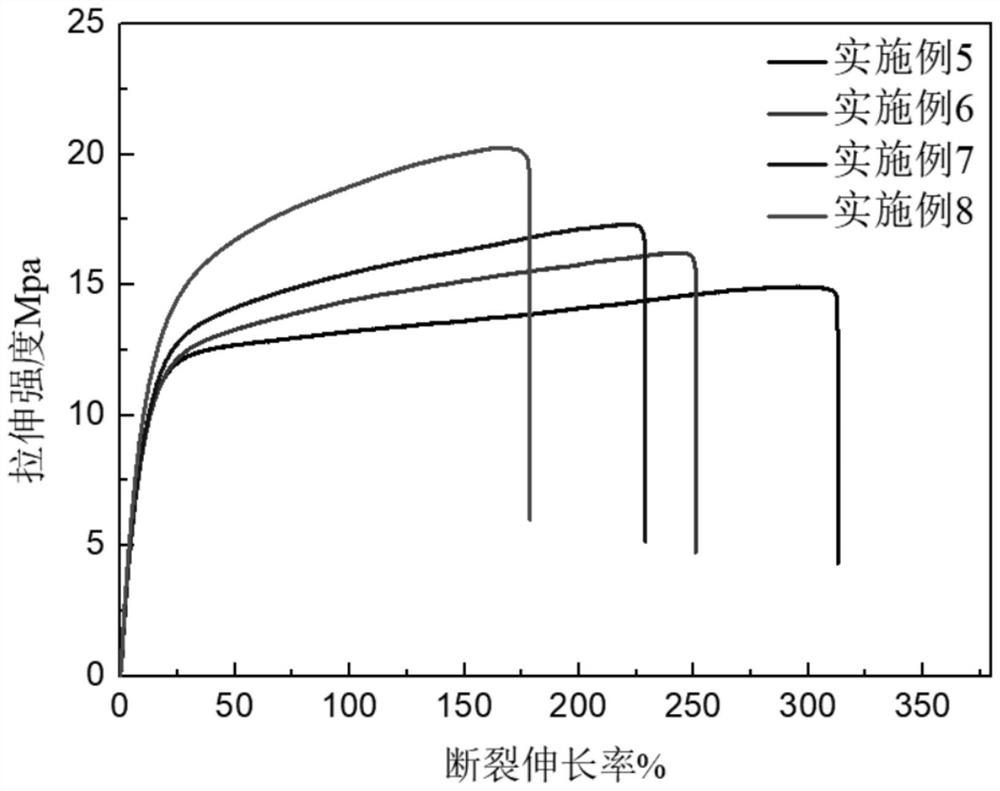

Examples

Embodiment 1

[0033] A PBAT / PLA / CaCO 3 Fully biodegradable composite material, including the following steps:

[0034] (1) Preparation of modified inorganic filler: Take 20 parts of calcium carbonate and dry it in a vacuum drying oven at 80°C for 12 hours. After drying, add 0.20 parts of titanate coupling agent and react in a high-speed mixer at 100°C for 20 minutes to obtain activated carbonic acid calcium.

[0035] (2) Preparation of PBAT-based fully degradable materials: First, dry 75 parts of PBAT and 5 parts of PLA in a vacuum drying oven at 80°C for 12 hours, add 0.75 parts of ADR chain extender to the dried PBAT, mix well and then add banburying In the machine, the speed of the internal mixer is 50r / min, the temperature is 170°C, and the time is 5min; then, the internal mixer and the micro-injection molding machine are used to blend and inject PBAT, PLA and CaCO3 with different mass ratios to prepare dumbbell-shaped splines. The speed of the internal mixer is 50r / min, the temperatu...

Embodiment 2

[0038] A PBAT / PLA / CaCO 3 Fully biodegradable composite material, including the following steps:

[0039] (1) Preparation of modified inorganic filler: Take 25 parts of calcium carbonate and dry it in a vacuum drying oven at 80°C for 12 hours. After drying, add 0.25 parts of titanate coupling agent and react in a high-speed mixer at 100°C for 20 minutes to obtain activated carbonic acid calcium.

[0040](2) Preparation of PBAT-based fully degradable materials: First, dry 70 parts of PBAT and 5 parts of PLA in a vacuum drying oven at 80°C for 12 hours, add 0.7 parts of ADR chain extender to the dried PBAT, mix well and then add banburying In the machine, the speed of the internal mixer is 50r / min, the temperature is 170°C, and the time is 5min; then, the internal mixer and the micro-injection molding machine are used to blend and inject PBAT, PLA and CaCO3 with different mass ratios to prepare dumbbell-shaped splines. The speed of the internal mixer is 50r / min, the temperature...

Embodiment 3

[0043] A PBAT / PLA / CaCO 3 Fully biodegradable composite material and preparation method thereof, comprising the following steps:

[0044] (1) Preparation of modified inorganic filler: Take 30 parts of calcium carbonate and dry it in a vacuum oven at 80°C for 12 hours. After drying, add 0.3 parts of titanate coupling agent and react in a high-speed mixer at 100°C for 20 minutes to obtain activated carbonic acid calcium.

[0045] (2) Preparation of PBAT-based fully degradable materials: First, dry 65 parts of PBAT and 5 parts of PLA in a vacuum drying oven at 80°C for 12 hours, add 0.65 parts of ADR chain extender to the dried PBAT, mix well and add banburying In the mixer, the speed of the internal mixer is 50r / min, the temperature is 170°C, and the time is 5min; then, the chain-extended PBAT, PLA and CaCO 3 Dumbbell-shaped splines were prepared by blending injection molding. The speed of the internal mixer was 50r / min, the temperature was 170°C, and the time was 10min. The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com