Method for promoting clostridium butyricum to form spores and microecological preparation and application thereof

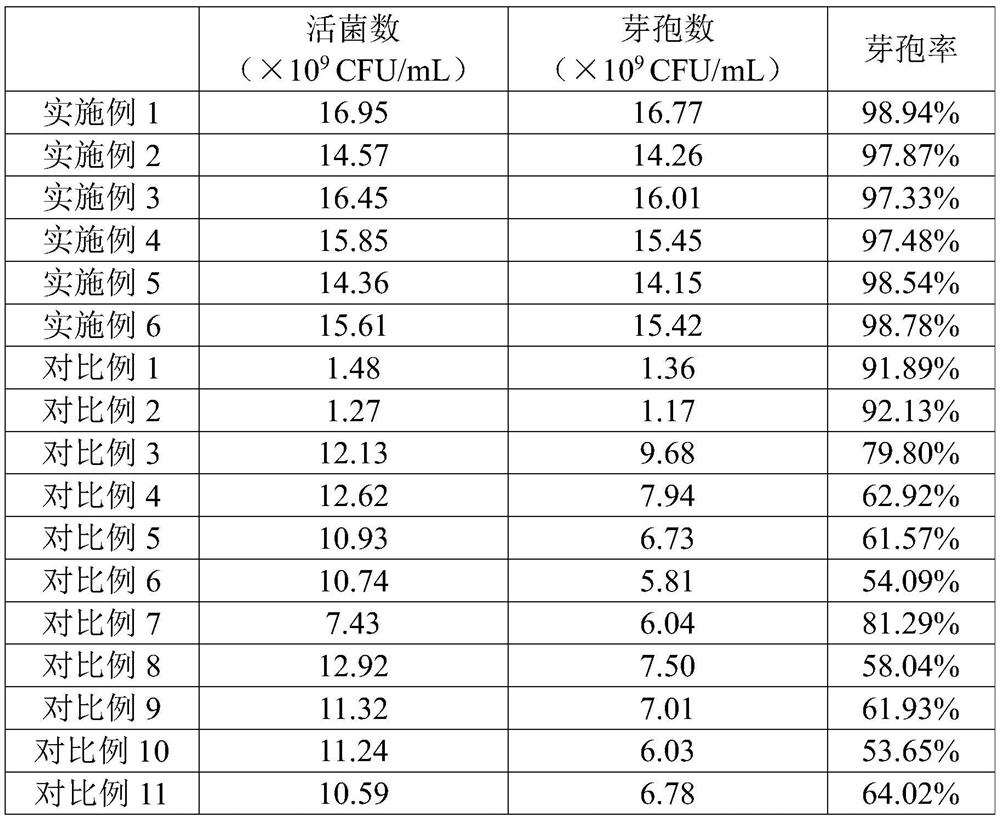

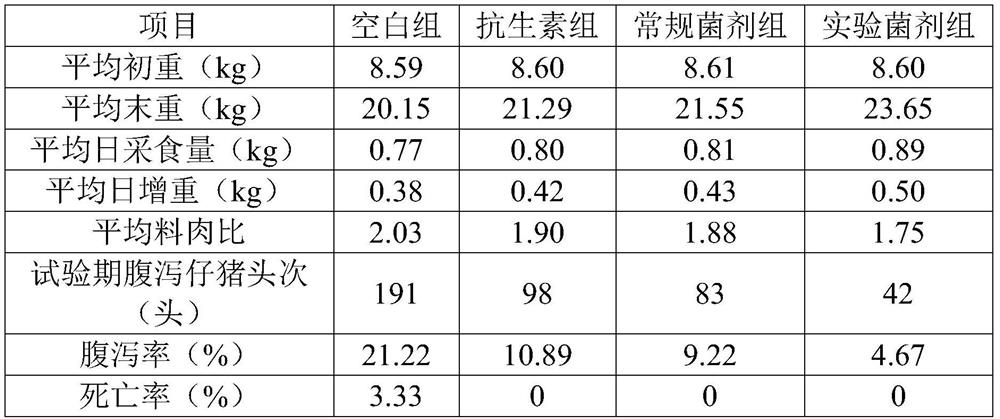

A technology of Clostridium butyricum and inactivation of Clostridium butyricum, which is applied in the direction of using spores, methods based on microorganisms, applications, etc., can solve the problems of low total yield, short shelf life, late Clostridium butyricum, etc., and achieve Increase the amount of viable bacteria and spore rate, increase feed intake, and reduce diarrhea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

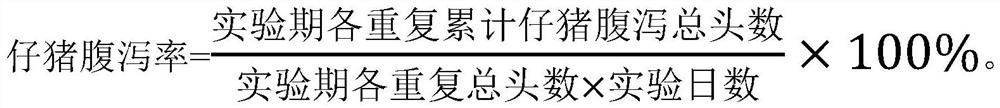

Examples

preparation example Construction

[0047]Specifically, the preparation method of the inactivated Clostridium butyricum sludge comprises: inoculating the Clostridium butyricum into the induction medium at a volume ratio of 1-2%, and statically culturing at 36-38° C. for 16-18 hours; In the boiling water bath for 20-40min, the solid-liquid separation is carried out after detecting no live bacteria. There are many ways of solid-liquid separation, including but not limited to centrifugation or filtration; in this application, it is preferred to use centrifugation for solid-liquid separation, centrifuge at 8000-12000rpm for 8-12min, remove the supernatant to obtain inactivated butyric acid shuttle Bacteria slime.

[0048] When the bacillus group forms spores under the harsh environment in nature, only part of the bacteria will form spores, and the other part of the bacteria will disintegrate and die. Studies have shown that this is mainly because during the spore formation process of bacillus, It will release subst...

Embodiment 1

[0056] The present embodiment provides a method for promoting the formation of spores by Clostridium butyricum, comprising the steps of:

[0057] S1. Prepare seed solution.

[0058] Clostridium butyricum was inoculated into a 1L conventional shake flask with a liquid content of 800ml according to a volume ratio of 1%, and cultured statically at 36-38° C. for 30 hours to obtain a Clostridium butyricum seed liquid. The seed medium in the shake flask was RCM liquid medium.

[0059] S2, expansion of fermenter.

[0060] The seed solution is inoculated into the fermentation medium at a volume ratio of 0.3%. When the seed solution is inoculated, the temperature is controlled at 36-38° C., the rotational speed is controlled at 50 rpm, and there is no ventilation. After seed liquid inoculation is completed, adjust the pH of the fermentation medium to ≥6.5 with 10% sodium hydroxide solution, and continuously control the pH of the fermentation medium to ≥6.5 during the entire expansion...

Embodiment 2

[0066] This embodiment is the same as other step parameters of Embodiment 1, the difference is only in:

[0067] The fermentation medium in the fermenter in step S2 consists of: glucose 8g / L, yeast powder 3g / L, peptone 8g / L, corn flour 8g / L, beef extract powder 8g / L, sodium acetate 3g / L, hydrogen phosphate Dipotassium 1.8g / L, ferrous sulfate 1.8g / L, sodium alginate 4g / L, agar 0.6g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com