Method for removing nitric oxide in kiln tail gas by using carbon dioxide catalytic conversion product

A technology for catalytic conversion and carbon dioxide, which is applied in the production of hydrocarbons from carbon oxides, carbon compound catalysts, chemical instruments and methods, etc., can solve problems such as process design uncertainty, and achieve the purpose of suppressing the effect of deactivation, improving conversion efficiency, and promoting The effect of the reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

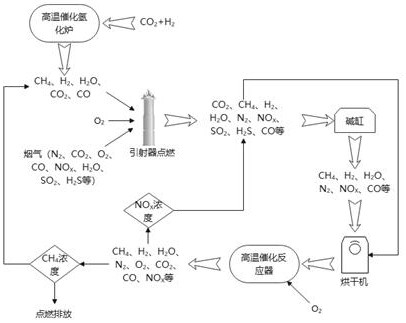

[0023] A method for removing nitrogen oxides in kiln tail gas by using carbon dioxide catalytic conversion products, comprising the following steps:

[0024] 1) Add 1 equivalent of CO 2 and 5 equivalents of H 2 Placed in a high temperature catalytic hydrogenation furnace, using ZrO 2 Catalyst loaded with Ni, reacted at 350°C for 4.5h, CH 4 The yield is close to 80%, and the resulting methane gas mixture contains CH from large to small in component content 4 、H 2 、H 2 O.CO 2 and CO components;

[0025] 2) Take the flue gas from the lime kiln, which contains N according to the component content from large to small 2 , CO 2 , O 2 , CO, NO X 、H 2 O, SO 2 、H 2 S component, methane mixed gas, newly blown O 2 And after the flue gas is mixed according to the volume ratio of 3:1:2, it is guided to the burner by the ejector to ignite, and the flame is completely extinguished and naturally extinguished, the combustion heat is collected, and high-temperature exhaust gas is g...

Embodiment 2

[0033] All steps are exactly the same as in Example 1, the difference is that the hydrogenation reaction principle in step 1) of Example 1 is replaced by: 1 equivalent of CO 2 and 6 equivalents of H 2 , examine different H 2 Quantity versus CH 4 with NO X The efficiency of the denitrification reaction, test run, a single NO with a high temperature catalytic reactor X The conversion rate, the number of cycles of the tail gas, and the number of cycles of the exhaust tail gas are process parameters, and are compared with Example 1.

Embodiment 3

[0035] All steps are exactly the same as in Example 1, the difference is that the hydrogenation reaction principle in step 1) of Example 1 is replaced by: 1 equivalent of CO 2 and 7 equivalents of H 2 , examine different H 2 Quantity versus CH 4 with NO X The efficiency of the denitrification reaction, test run, a single NO with a high temperature catalytic reactor X The conversion rate, the number of cycles of the tail gas, and the number of cycles of the exhaust tail gas are process parameters, and are compared with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com