Hot press molding method and device for two-component single polymer composite product

A technology of thermoforming and composite materials, applied in the direction of fabrics, manufacturing tools, textiles and papermaking, etc., can solve the problems of weakening, limited improvement of mechanical strength, inability to obtain maximum strength, etc., achieving low density and high recycling rate , the effect of excellent creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

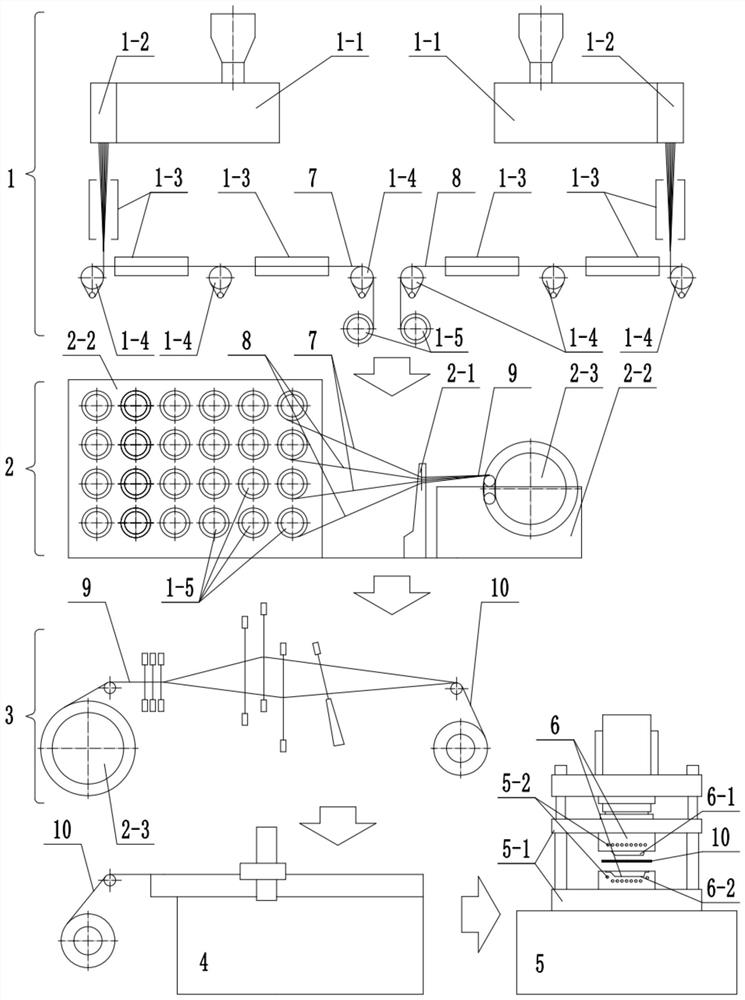

[0052] A two-component single-polymer composite product thermocompression forming device, which consists of a spinning machine (1), a warping machine (2), a weaving machine (3), a cutting machine (4), and a hot press machine (5) And mold (6), described mold (6) is made up of convex mold (6-1) and concave mold (6-2), and cavity shape is designed according to product shape; Described heat press (5) includes clamping mold System (5-1), temperature control system (5-2), mold (6) is installed on the clamping system (5-1) of hot press (5); temperature control system (5-2) comprises heating wire , cooler, thermocouple and controller, the punch (6-1) and the die (6-2) are provided with a heating wire channel, a cooling water channel and a thermocouple installation hole, the heating wire is arranged in the heating wire channel, cooling The water channel is connected with the cooler through a pipe joint and a water pipe, and the thermocouple is arranged in the thermocouple installation ...

Embodiment 2

[0067] Polypropylene is produced by addition polymerization of propylene. It is a colorless, odorless, non-toxic, translucent, lightweight thermoplastic polymer with chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties and Good high wear resistance processing performance, etc. The chemical formula is (C 3 h 6 ) n , the density is 0.89~0.91g / cm 3 , The operating temperature range is -30~140℃. Polypropylene is widely used in the production of clothing, blankets and other fiber products, textiles, medical equipment, automobiles, bicycles, electronic appliances, construction, pipelines, chemical containers, etc., and is also used in food and pharmaceutical packaging. And because of its plasticity, polypropylene materials are gradually replacing wooden products, and their high strength, toughness and high wear resistance have gradually replaced the mechanical functions of metals. In addition, polypropylene has good grafting and compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com