Phosphogypsum hardening agent and preparation method and application thereof

A technology for phosphogypsum and hardener, which is applied in the field of phosphogypsum hardener and its preparation, can solve the problems of poor performance and difficulty in processing and utilizing a large amount of phosphogypsum, and achieves improved retardation properties, good anti-carbonation performance, and improved anti-scour performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the present invention, the preparation method of the modifying agent preferably includes the following steps: drying carbide slag, steel slag and quicklime respectively, so that the moisture content of the calcium carbide slag, steel slag and quicklime are independently ≤5wt%, and then carry out mixed to obtain the modifier. In the present invention, the mixing method is preferably grinding; the present invention does not have any special limitation on the grinding process, and it can be carried out by a process well known to those skilled in the art.

[0038] In the present invention, the mass percentage of CaO in the modifier is preferably ≥ 60 wt%, more preferably ≥ 65 wt%.

[0039] In the present invention, controlling the calcium oxide in the modifying agent within the above content range is beneficial to ensure the chemical properties of the modifying agent.

[0040] Based on the parts by weight of the phosphogypsum, the phosphogypsum hardening agent of the pres...

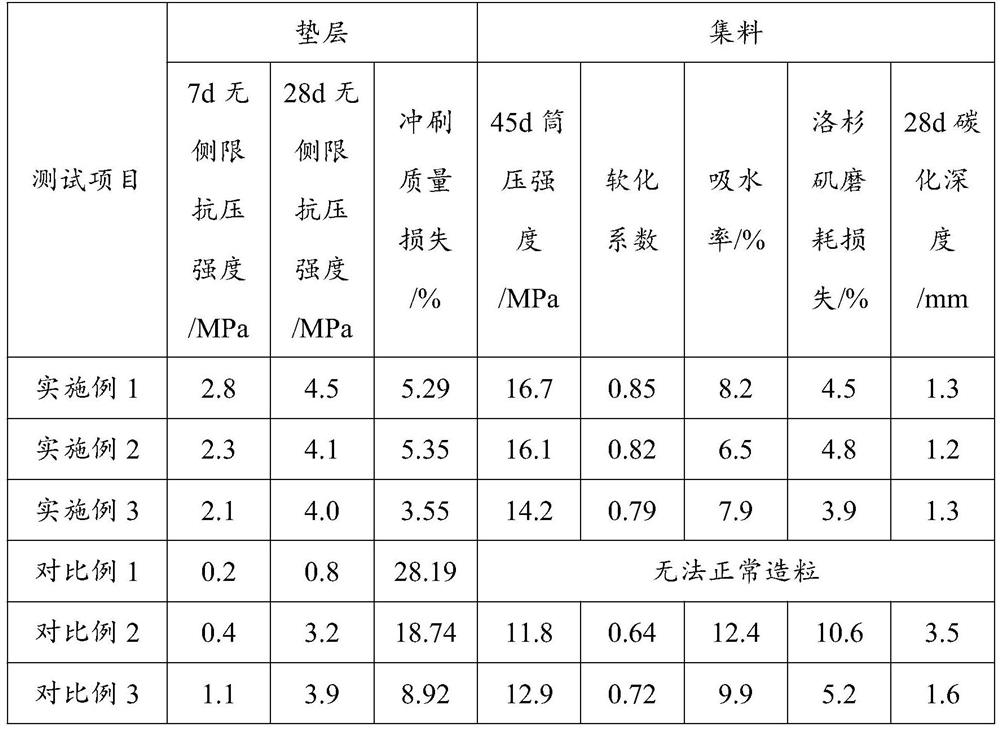

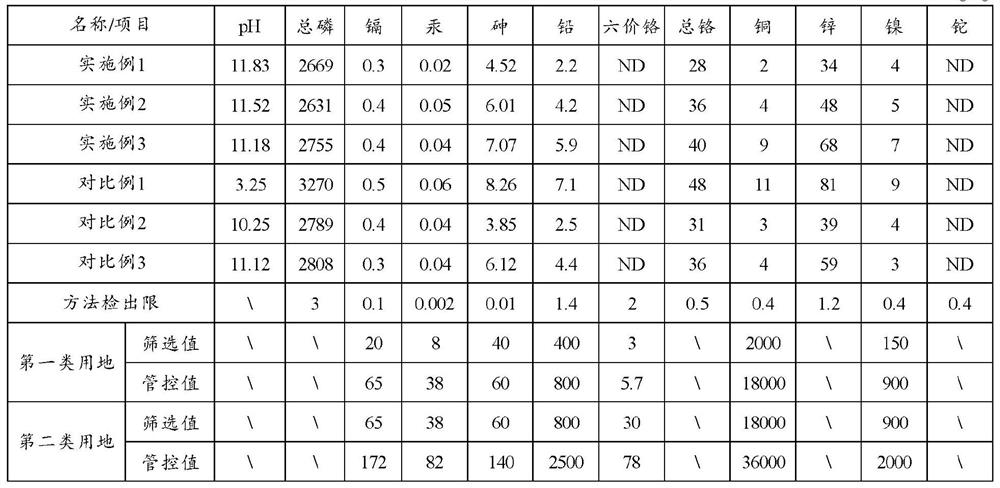

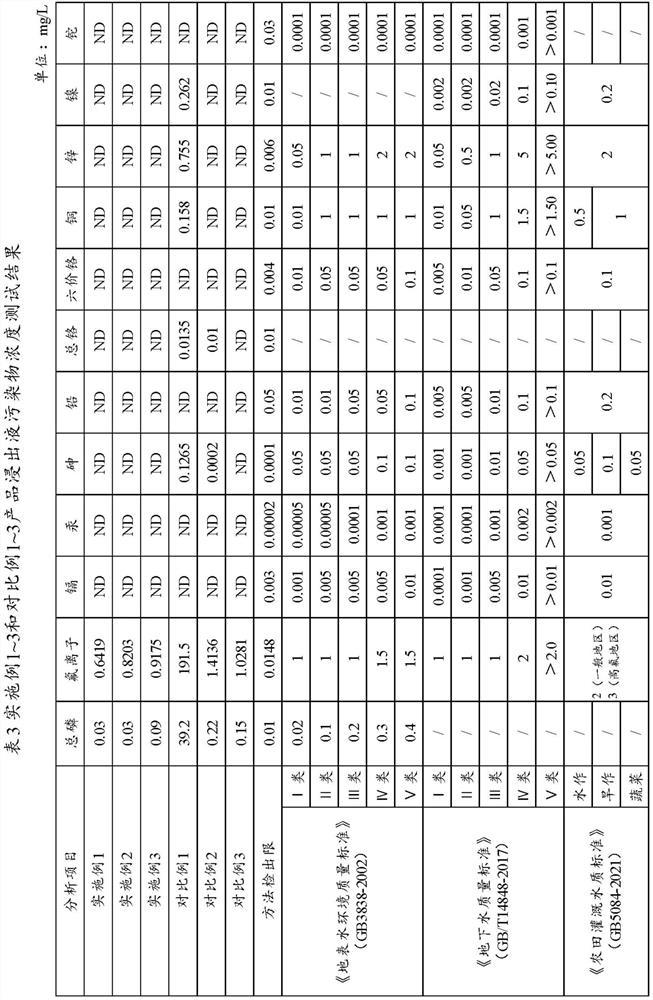

Embodiment 1

[0062] The composition of phosphogypsum hardener:

[0063] Phosphogypsum: 1660 parts; undisturbed phosphogypsum stored for more than 3 years, with a moisture content of 13.55wt%, CaSO 4 The content is 91wt%, the content of water-soluble phosphorus is 0.28wt%, the content of water-soluble fluorine is 0.08wt%, and the pH value is 4.3;

[0064]Modifier (CaO content: 64.8%): 24 parts; composition: calcium carbide slag 35%, steel slag 30%, quicklime 35%; calcium carbide slag, steel slag and quicklime are dried to a moisture content of ≤ 5% and then ground mix;

[0065] Active mineral admixture (the sieve residue after passing through a 45μm aperture sieve is 15.2%): 111.8 parts; composition: mineral powder, fly ash and silica fume with a mass ratio of 8:1:1; the mineral powder is S95 grade Blast furnace slag powder, activity index 99%; fly ash is class II class C fly ash; SiO in silica fume 2 The content is 97%;

[0066] Cement: 129.75 parts; the cement is P.O 42.5R ordinary Po...

Embodiment 2

[0077] The composition of phosphogypsum hardener:

[0078] Phosphogypsum: 1660 parts; undisturbed phosphogypsum stored for more than 2 years, with a moisture content of 15.25wt%, CaSO 4 The content is 87wt%, the content of water-soluble phosphorus is 0.42wt%, the content of water-soluble fluorine is 0.09wt%, and the pH value is 3.6;

[0079] Modifier (CaO content: 62.4%): 28 parts; composition: 40% carbide slag, 30% steel slag, 30% quicklime; dry carbide slag, steel slag and quicklime separately until the moisture content is ≤5%, then grind mix;

[0080] Active mineral admixture (the sieve residue after passing through a 45 μm aperture sieve is 12.8%): 120 parts; composition: mineral powder; the mineral powder is S105 grade granulated blast furnace slag powder, and the activity index is 108%;

[0081] Cement: 126 parts; the cement is P.O 42.5R ordinary Portland cement, and the 3d compressive strength is 2.0MPa;

[0082] Metakaolin: 33 parts; the metakaolin is low-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com