Casting ceramic filter based on 3D printing and preparation method thereof

A ceramic filter and 3D printing technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of only 20-30mm/h, poor high temperature resistance of the filter, insufficient filtration of metal solution, etc. problems, to achieve the effect of speeding up the filling speed, enhancing the filtering effect, improving the surface quality and molding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Ceramic Filter Structure Design

[0041] Gray cast iron is selected as molten metal, the porosity used to filter gray cast iron is generally 20ppi, and the filtration capacity per unit area ranges from 2.0 to 3.8kg / cm 2 .

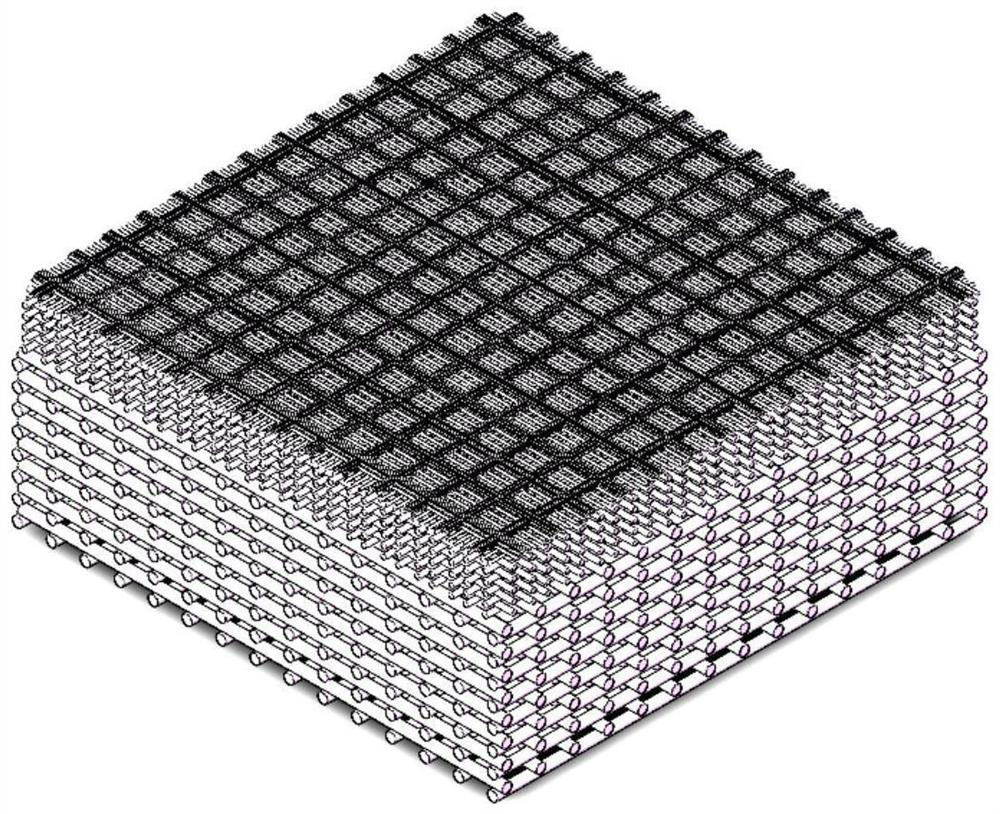

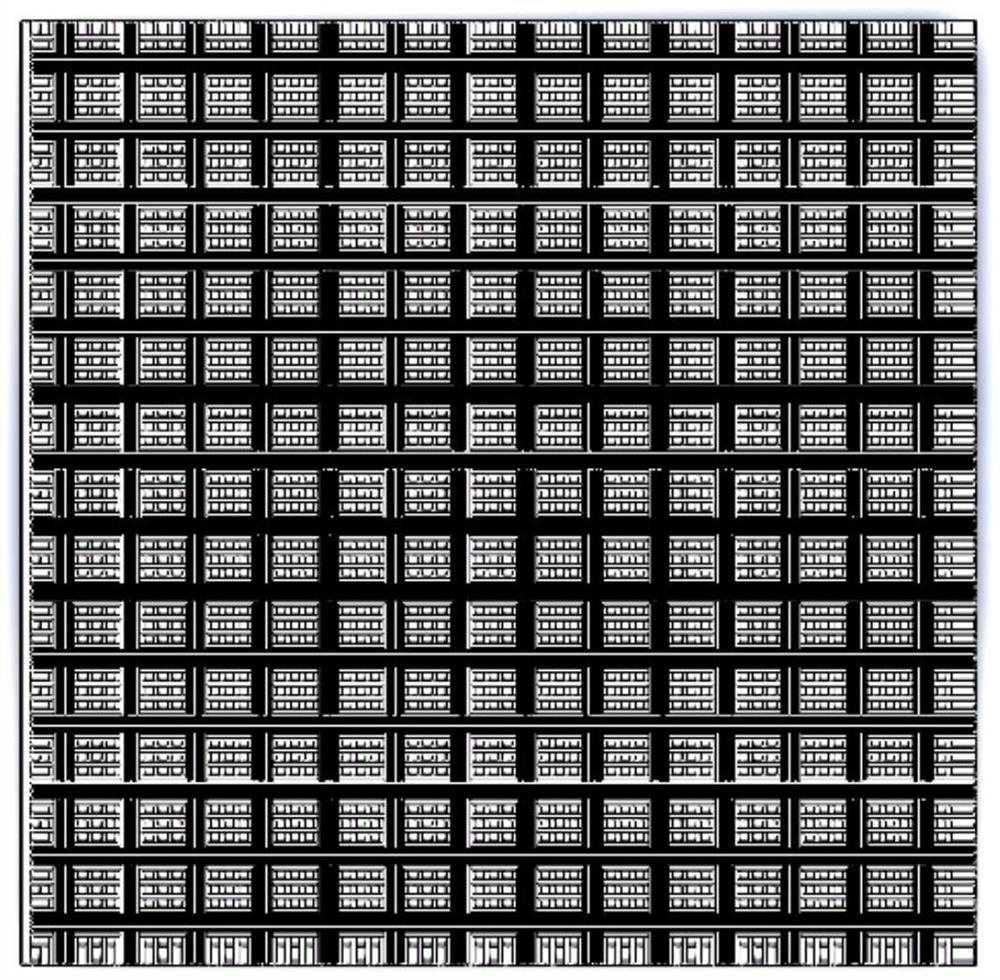

[0042]Based on the above data, use 3D software to design the upper and lower surfaces of the filter to be grid-shaped, with length, width and height of 100mm, 100mm, and 20mm respectively; the number of printed gradient layers is 10, the gradient layer thickness is designed to be 2mm, and the line width is 100μm; the pores The porosity transitions from 5ppi in the first layer to 20ppi in the tenth layer with the trend of increasing 1.5ppi per layer, realizing the gradient change of porosity from the upper end to the lower end of the filter;

[0043] Then import the 3D graphics to the slicing software in STL file format, and slice the filter model layered after considering factors such as printing time, material curable thickness, and precisi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com