Amino acid compound foliar fertilizer and application thereof

A foliar fertilizer and amino acid technology, applied in urea compound fertilizer, application, ammonium orthophosphate fertilizer, etc., to achieve the effect of promoting quality improvement, easy implementation, environmental protection and pollution-free production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

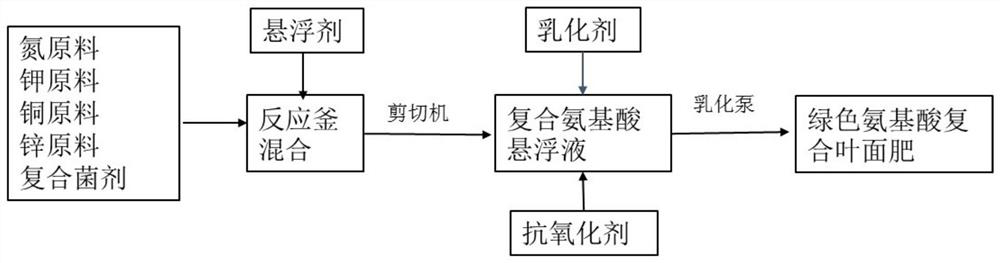

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the preparation method of the amino acid compound foliage fertilizer of celery

[0037] 1. Formula of amino acid compound foliar fertilizer:

[0038] The nitrogen raw materials used are urea and 50% (V / V) plant-source enzymolysis compound amino acid concentrate (plant-source enzymolysis compound amino acid concentrate was purchased from Sichuan Haoqing Biotechnology Co., Ltd., wherein the total amino acid content ≥ 50%, total nitrogen ≥20%, ρ=1.5g / ml); the potassium raw material is potassium dihydrogen phosphate; the copper raw material is copper sulfate pentahydrate, the zinc raw material is zinc sulfate heptahydrate, and the compound bacterial agent is AM fungus and bacillus at a ratio of 1:1 Mixing, the number of viable bacteria is ≥ 2 billion / g, the AM fungus used in this example is Glomus mosei, and the Bacillus used is Bacillus thuringiensis.

[0039] Present embodiment establishes 4 kinds of formulas altogether, and each raw material is specific as...

Embodiment 2

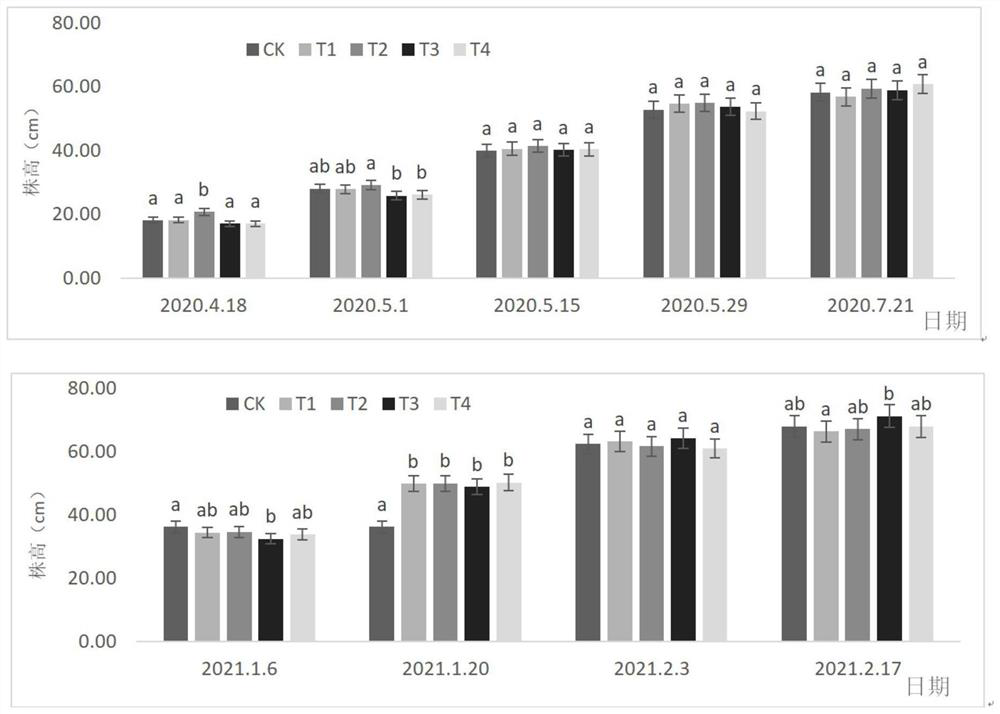

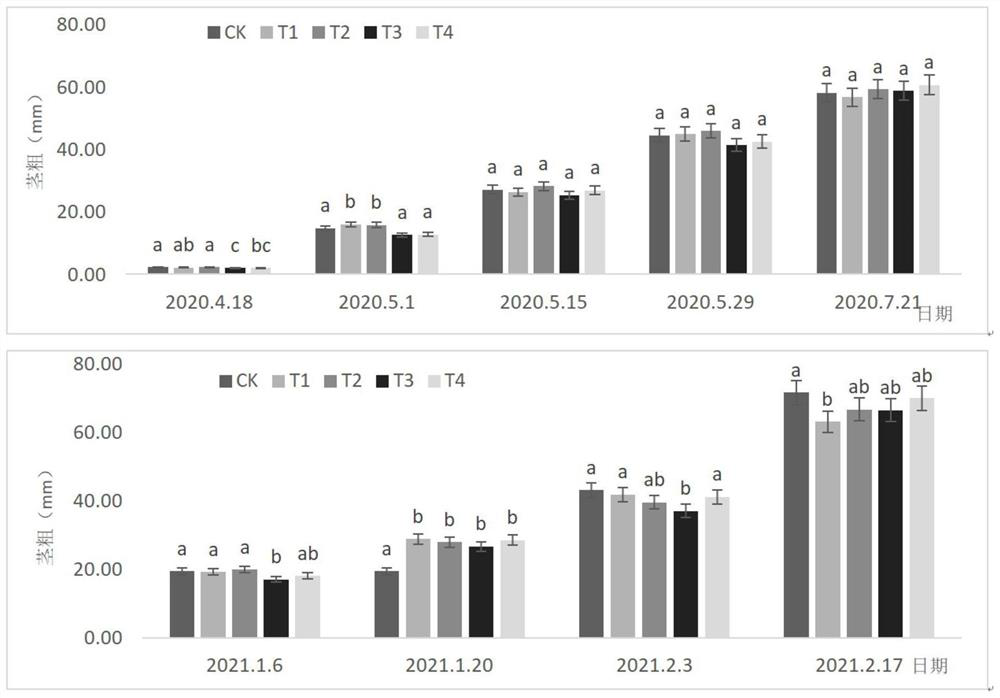

[0052] Embodiment 2, the application effect test of the amino acid compound foliar fertilizer of celery

[0053] 1. Implementation location:

[0054] The experiment was carried out in the multi-span greenhouse of Beijing Academy of Agriculture and Forestry Sciences, which is located inside the Beijing Academy of Agriculture and Forestry Sciences (39°94′88″N and 116°29′08″E) in Shuguang Garden, Haidian District. It has a continental monsoon climate with sufficient light and heat, with an average annual temperature of 10-12°C and an average annual rainfall of 664mm. Built since 2010, with an area of 10,000m 2 , Since its establishment has been the anniversary production facility vegetables.

[0055] 2. Test treatment:

[0056] Choose celery as test material, utilize 4 kinds of compound amino acid foliar fertilizers prepared in embodiment 1 to test, and set control group, total 5 processes, each process repeats 3 times, and each repeats as a pot (5 strains) Celery, a total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com