Method for recovering valuable metal in positive plate of lithium battery

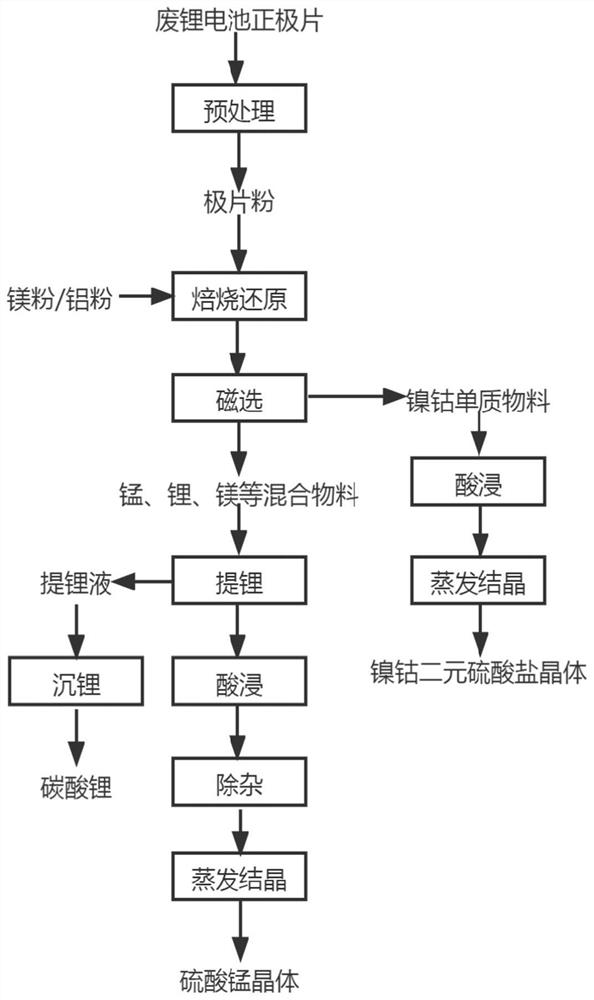

A recovery method and technology for valuable metals, applied in the field of recovery of valuable metals in positive plates of lithium batteries, can solve the problems of complex process, long process, difficult treatment of organic waste water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

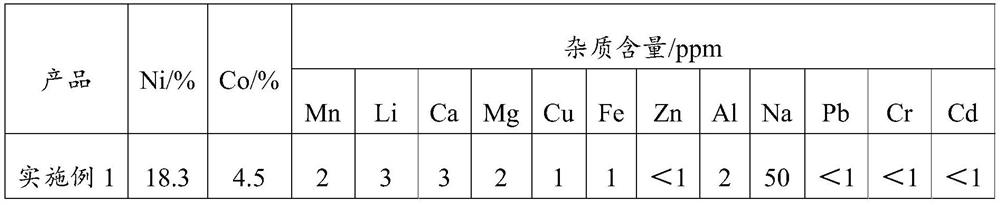

Embodiment 1

[0119] This embodiment provides a method for recovering valuable metals in the positive electrode sheet of a lithium battery. The specific process is as follows:

[0120]A1. Pretreatment: The waste lithium battery ternary positive electrode sheet (from Guangdong Bangpu Recycling Co., Ltd., by mass percentage, containing Ni47.3%, Co6.2%, Mn5.9%, Li7.2%) in turn The crushing, sorting and sieving processes are carried out to obtain pole piece powder.

[0121] A2. Deep reduction of aluminum powder:

[0122] A21. mix the pole piece powder and aluminum powder obtained in step A1 according to the mass ratio of 1:0.5,

[0123] A22. Place the powder obtained in step A21 in a tube furnace, raise the temperature from 25°C to 400°C at a rate of 1°C / min under a nitrogen atmosphere, then roast for 4 hours, and cool;

[0124] A3. Magnetic separation: the pole piece powder obtained in step A2 is separated by magnetic separation under the condition that the magnetic field strength is 10T wit...

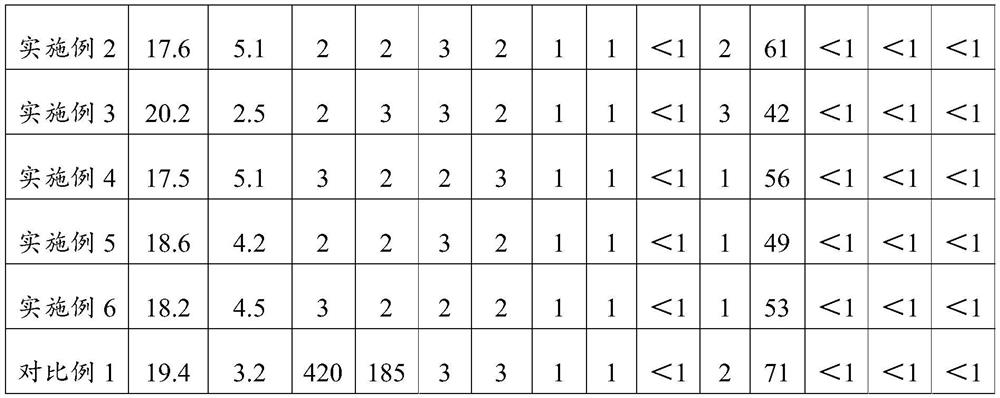

Embodiment 2

[0153] This embodiment provides a method for recovering valuable metals in the positive electrode sheet of a lithium battery. The specific process is as follows:

[0154] A1. Pretreatment: the waste lithium battery ternary positive electrode sheet (provided by Guangdong Bangpu Recycling Co., Ltd., by mass percentage, containing Ni36.5%, Co11.3%, Mn12.4%, Li7.1%) The steps of crushing, sorting and sieving are carried out in sequence to obtain pole piece powder.

[0155] A2. Deep reduction of aluminum powder:

[0156] A21. mix the pole piece powder and aluminum powder obtained in step A1 according to the mass ratio of 1:1.2,

[0157] A22. Place the powder obtained in step A21 in a tube furnace, raise the temperature from 25°C to 600°C at a rate of 5°C / min under a nitrogen atmosphere, then roast for 2 hours, and cool;

[0158] A3. Magnetic separation: the pole piece powder obtained in step A2 is separated by magnetic separation under the condition that the magnetic field streng...

Embodiment 3

[0185] This embodiment provides a method for recovering valuable metals in the positive electrode sheet of a lithium battery. The specific process is as follows:

[0186] A1. Pretreatment: The waste lithium battery ternary positive electrode sheet (from Guangdong Bangpu Recycling Co., Ltd., by mass percentage, containing Ni31.7%, Co11.4%, Mn16.5%, Li7.1%) in turn The crushing, sorting and sieving processes are carried out to obtain pole piece powder.

[0187] A2. Deep reduction of aluminum powder:

[0188] A21. mix the pole piece powder and aluminum powder obtained in step A1 according to the mass ratio of 1:1,

[0189] A22. Place the powder obtained in step A21 in a tube furnace, raise the temperature from 25°C to 500°C at a rate of 2°C / min under a nitrogen atmosphere, then roast for 3 hours, and cool;

[0190] A3. Magnetic separation: the pole piece powder obtained in step A2 is separated by magnetic separation under the condition that the magnetic field strength is 20T wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com