Method for preparing aluminum nitride crystal by adopting gas phase transmission

A vapor phase transport, aluminum nitride technology, used in chemical instruments and methods, crystal growth, single crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

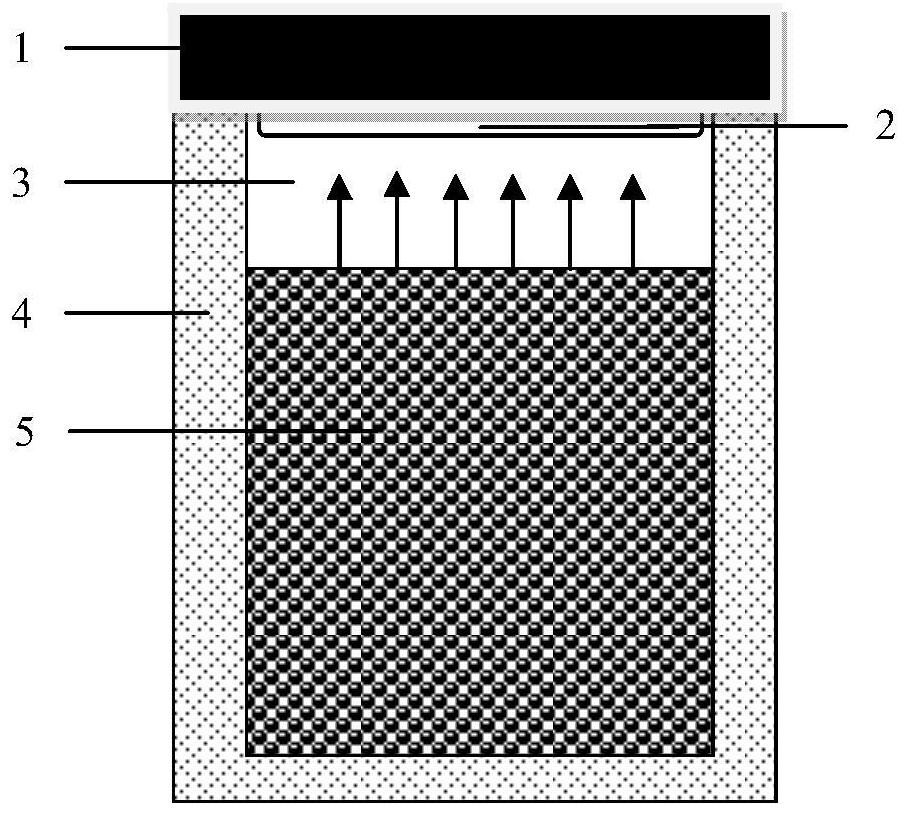

[0027] Example 1: The original material in this embodiment is an aluminum nitride material, and the number of atoms of the nitrogen element of the feedstock is 0.95, the amount of impurity element carbon, oxygen is about 2 × 10 18 cm -3 The crystal growth temperature is 2150 ° C, the growth atmosphere is 99.99% nitrogen, the growth air pressure is 600 mbar, and the specific crystal growth crucible apparatus is image 3 As shown, after the crystal is completed, the crucible cooling rate is 20 ° C / h.

[0028] The AlN crystals grown in this embodiment have a carbon impurity content of about 3 × 10 18 cm -3 The content ratio of nitrogen and aluminum element is about 0.87: 1, the crystal color is amber, and the absorption is 300 nm, and the transmission rate of 230 to 280 nm band is zero.

Embodiment 2

[0029] Example 2: Different in the present embodiment, the content of impurity element carbon and oxygen is about 2 × 10 17 cm -3 The remaining processes are the same.

[0030] Compared with Example 1, the AlN crystals grown in the present embodiment have a carbon impurity content of about 4 × 10. 17 cm -3 The ratio of nitrogen and aluminum element is about 0.9: 1, the crystal color is pale yellow, and the absorption is 210 nm, and the transmittance is 30% in the 230-280 nm band transmission rate.

Embodiment 3

[0031] Example 3: Different from Example 1, the raw material first employs aluminum nitride powder with purity ≥ 97.5%, and is sintered in a high temperature of 2250 ° C for 5 hours in a high temperature furnace of the tungsten system, obtain purity ≥99.99%, carbon impurity content About 4 × 10 17 cm -3 Aluminum nitride, after which a nitrogen ion is used to ion implantation in the raw material, and the ratio of the nitrogen element and the aluminum element in the aluminum nitride raw material is 1.08: 1, the remaining processes are the same.

[0032] Compared to Examples 1 and 2, Aln crystals grown in the present embodiment have a carbon impurity content of about 1 × 10 17 cm -3 The content ratio of nitrogen and aluminum element is about 1: 1, the crystal color is colorless, and its absorption is 210 nm, and the transmission rate of 230 to 280 nm band is 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com