Lead-free thin film with high energy storage density and wide working temperature, capacitor and preparation method of lead-free thin film

A technology with wide operating temperature and high energy storage density, applied in thin film/thick film capacitors, multilayer capacitors, fixed capacitor dielectrics, etc. The effect of polarization, increasing energy storage density, and increasing relaxation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

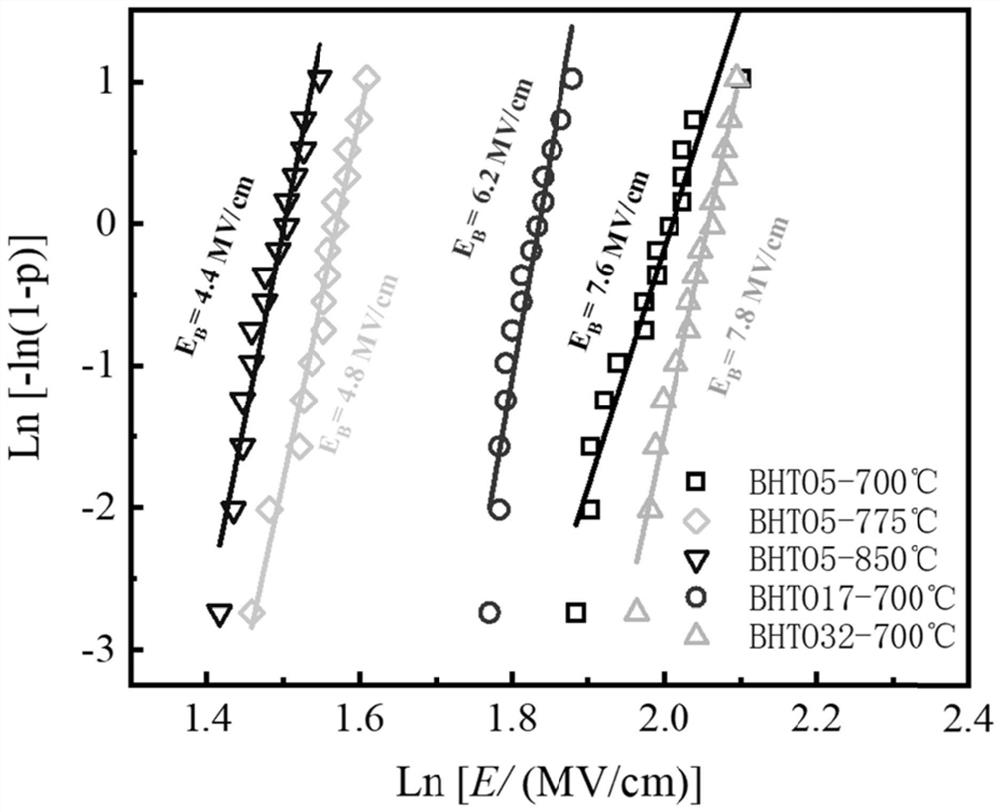

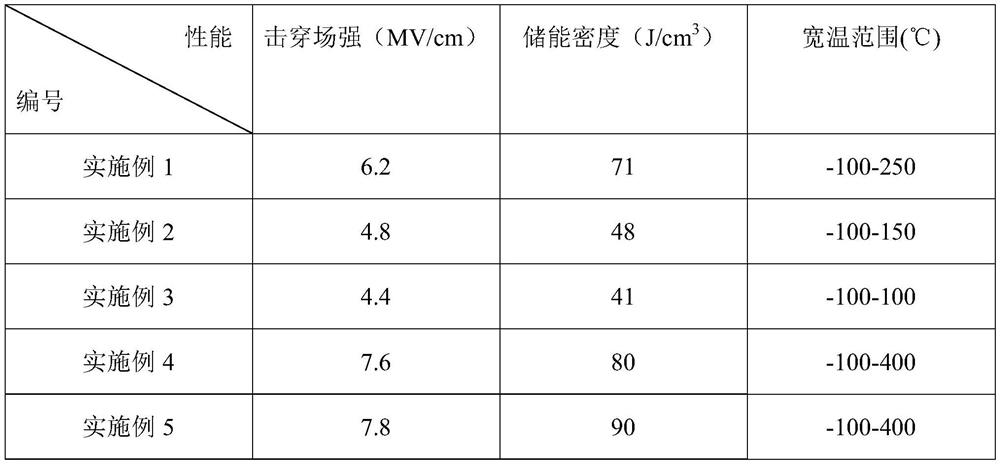

Examples

Embodiment 1

[0026] The preparation process of the capacitor of this embodiment is as follows:

[0027] Step 1. Target preparation: for growing BaHf 0.05 Ti 0.95 o 3 The ceramic target of the thin film adopts BaCO with a purity level of 99.99% 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100°C.

[0028] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating table, and the vacuum degree in the deposition chamber is less than 10 by using a mechanical pump and a molecular pump. -5 mbar.

[0029] Step 3. Ventilate and heat up: Infuse 200 mbar of argon gas and oxygen gas mixture with a volume ratio of 1 / 1, then raise the temperature of the sample stage to 700° C., and keep it warm for 10 minutes.

[0030] Step 4. Vacuumize and ventilate: then pump the deposition chamber until the a...

Embodiment 2

[0035] The preparation process of the capacitor of this embodiment is as follows:

[0036] Step 1. Target preparation: for growing BaHf 0.05 Ti 0.95 o 3 The ceramic target of the thin film adopts BaCO with a purity level of 99.99% 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100°C.

[0037] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating table, and the vacuum degree in the deposition chamber is less than 10 by using a mechanical pump and a molecular pump. -5mbar.

[0038] Step 3. Ventilate and heat up: inject 200 mbar of argon-oxygen gas mixture with a volume ratio of 1 / 1, then raise the temperature of the sample stage to 775° C., and keep it warm for 10 minutes.

[0039] Step 4. Vacuumize and ventilate: then pump the deposition chamber until the air pressu...

Embodiment 3

[0044] The preparation process of the capacitor of this embodiment is as follows:

[0045] Step 1. Target preparation: for growing BaHf 0.05 Ti 0.95 o 3 The ceramic target of the thin film adopts BaCO with a purity level of 99.99% 3 Powder, HfO 2 Powder and TiO 2 The powder is prepared by ceramic technology according to the ratio; when preparing ceramic targets, the sintering temperature is lower than the phase formation temperature of each system by 100°C.

[0046] Step 2, put the substrate, vacuum: Nb:SrTiO 3 The substrate is placed on the heating table, and the vacuum degree in the deposition chamber is less than 10 by using a mechanical pump and a molecular pump. -5 mbar.

[0047] Step 3. Ventilate and heat up: inject 200 mbar of argon-oxygen mixed gas with a volume ratio of 1 / 1, then raise the temperature of the sample stage to 850° C., and keep it warm for 10 minutes.

[0048] Step 4. Vacuumize and ventilate: then pump the deposition chamber until the air pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com