Semiconductor structure and forming method thereof

A technology of semiconductor and isolation structure, applied in the field of semiconductor structure and its formation, to achieve the effect of improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background art, the performance of the semiconductor structure formed by using the existing lateral double-diffused metal-oxide-semiconductor field effect transistor needs to be improved urgently. Now combine a semiconductor structure for description and analysis.

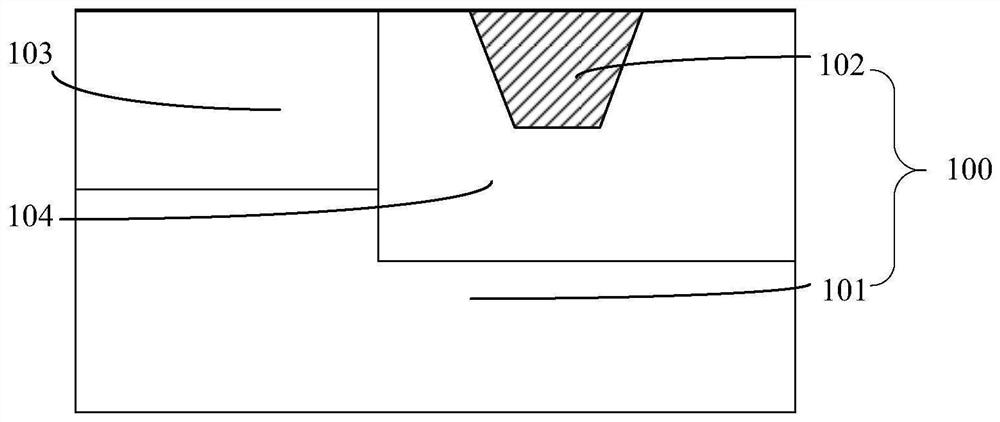

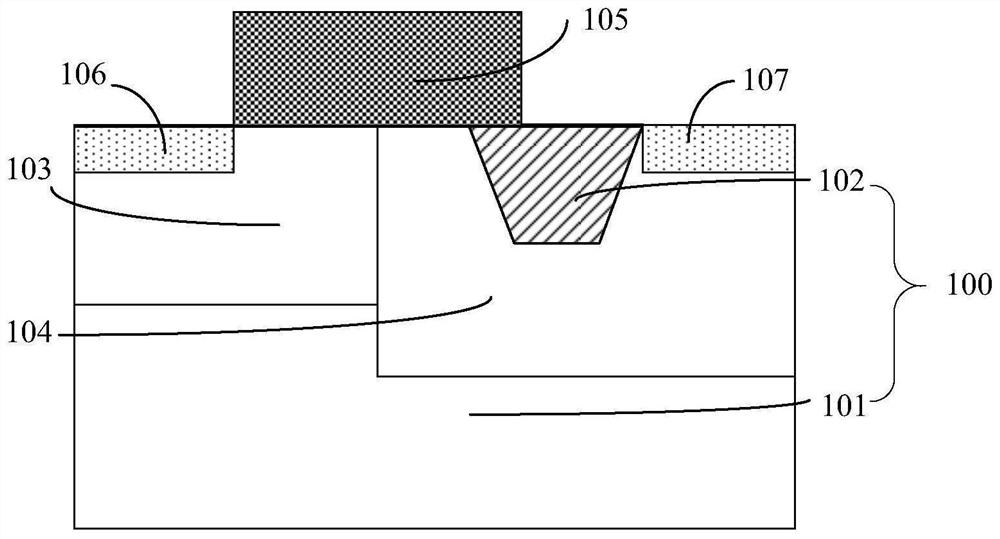

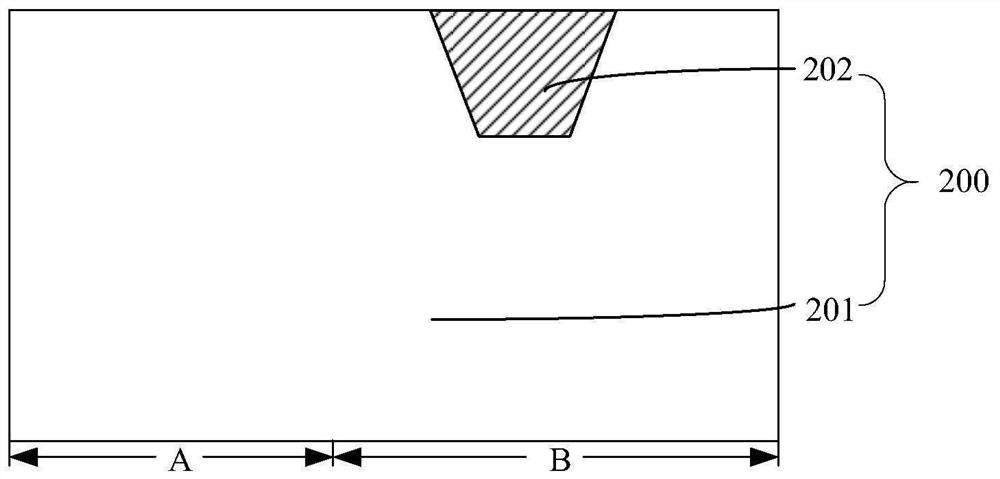

[0034] figure 1 It is a schematic cross-sectional structure diagram of a semiconductor structure.

[0035] Please refer to figure 1 , provide a substrate 100, the substrate includes a base 101, a field oxygen region 102 is formed in the substrate 100; a first photoresist layer is formed covering the surface of the field oxygen region 102 and part of the surface of the substrate 100 (not shown in the figure), implant N-type first dopant ions into the substrate 100 to form a body region 103, after forming the body region 103, remove the first photoresist layer; cover the body region 103 Forming a second photoresist layer (not shown in the figure), implanting P-type second dopant ions i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com