Refractory tungsten-tantalum alloy complex structural part and additive manufacturing forming method thereof

A complex structure, additive manufacturing technology, applied in the field of additive manufacturing to achieve the effect of reducing multiple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1. Put the tungsten-tantalum mixed powder in a vacuum drying oven, even the drying temperature is 100°C, the drying time is not less than 4 hours, and the powder is turned over at regular intervals to ensure sufficient drying.

[0036] Step 2. Put the dried tungsten-tantalum mixed powder into the powder supply cylinder of the forming equipment, install the scraper, level the substrate, and close the equipment hatch.

[0037] Step 3. Fill the equipment with high-purity argon gas so that the oxygen content inside the cavity is lower than 300ppm, and at the same time turn on the substrate heating, and set the substrate temperature to 150°C.

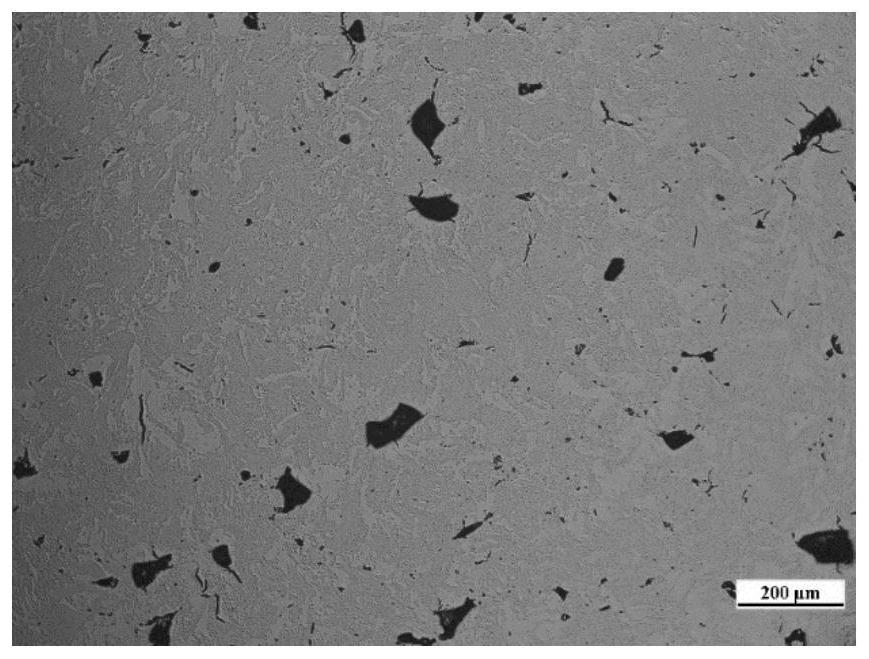

[0038] Step 4. Import the processed model into the equipment control software, set the process parameters including: laser power 300W, scanning speed 400mm / s, filling distance 0.08mm, powder layer thickness 0.03mm, scanning strategy is to rotate 67° layer by layer, and finally prepare A 10mm×10mm×5mm high-tungsten-tantalum alloy ...

Embodiment 2

[0040] In the example of the present invention, powder treatment and pre-forming treatment are identical with example 1, difference is:

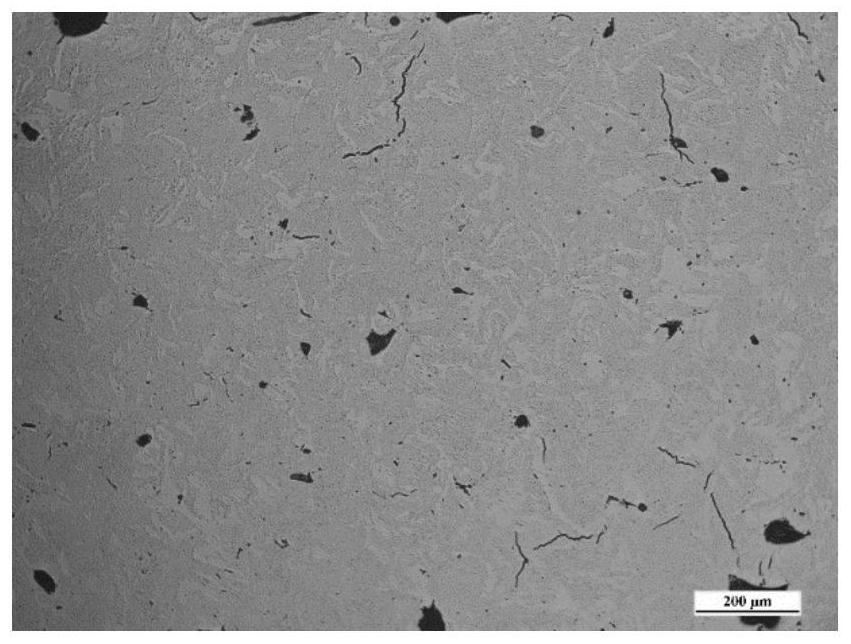

[0041] The setting process parameters include: laser power 300W, scanning speed 300mm / s, filling distance 0.08mm, powder layer thickness 0.03mm, scanning strategy is to rotate 67° layer by layer, and finally prepare a high-tungsten-tantalum alloy block of 10mm×10mm×5mm , and its corresponding light microscope topography is shown in figure 2 shown.

Embodiment 3

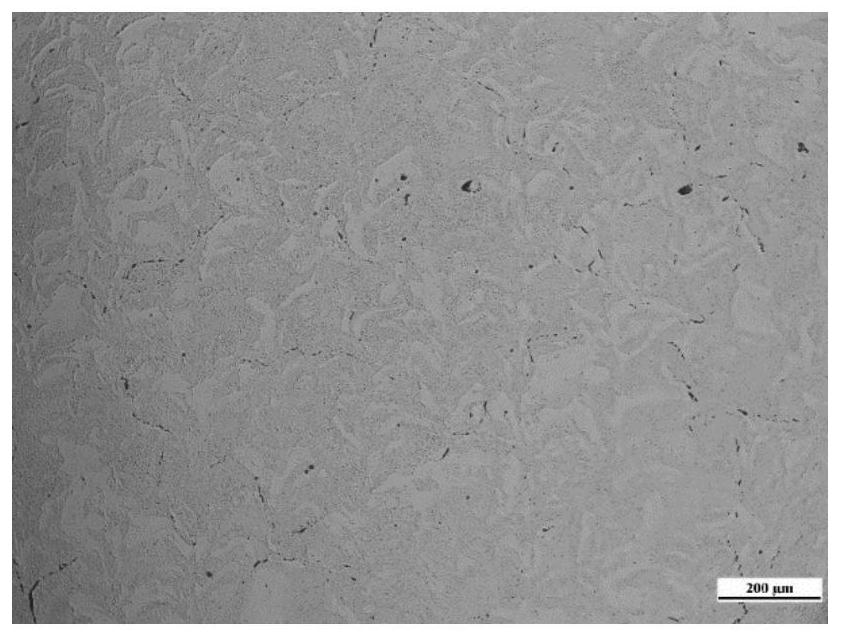

[0043] In the example of the present invention, the powder treatment and pre-forming treatment are the same as Example 1, the difference is that the setting process parameters include: laser power 370W, scanning speed 300mm / s, filling distance 0.08mm, powder layer thickness 0.03mm, scanning strategy is By rotating 67° layer by layer, a high-tungsten-tantalum alloy block of 10mm×10mm×5mm was finally prepared, and its corresponding light microscope morphology is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com