Electric flocculation-self-cleaning membrane wastewater treatment device

A wastewater treatment and self-cleaning membrane technology, applied in the field of water treatment, can solve problems such as rising of the conductive membrane interface, affecting the long-term operation performance of the reactor, membrane pollution, etc., achieve good treatment effect, achieve long-term stable operation, and good removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

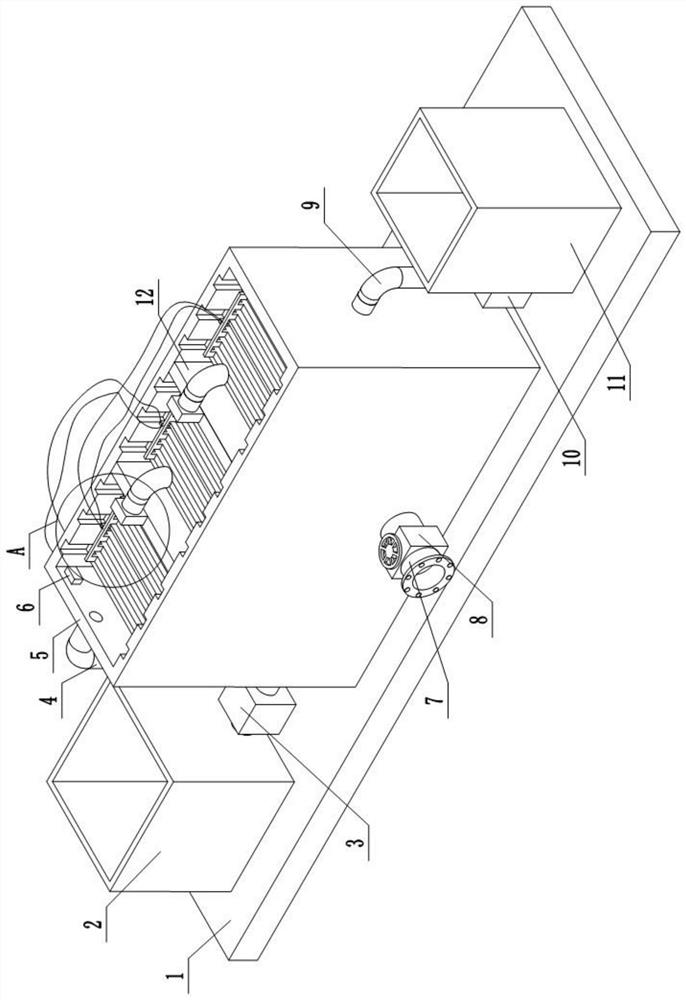

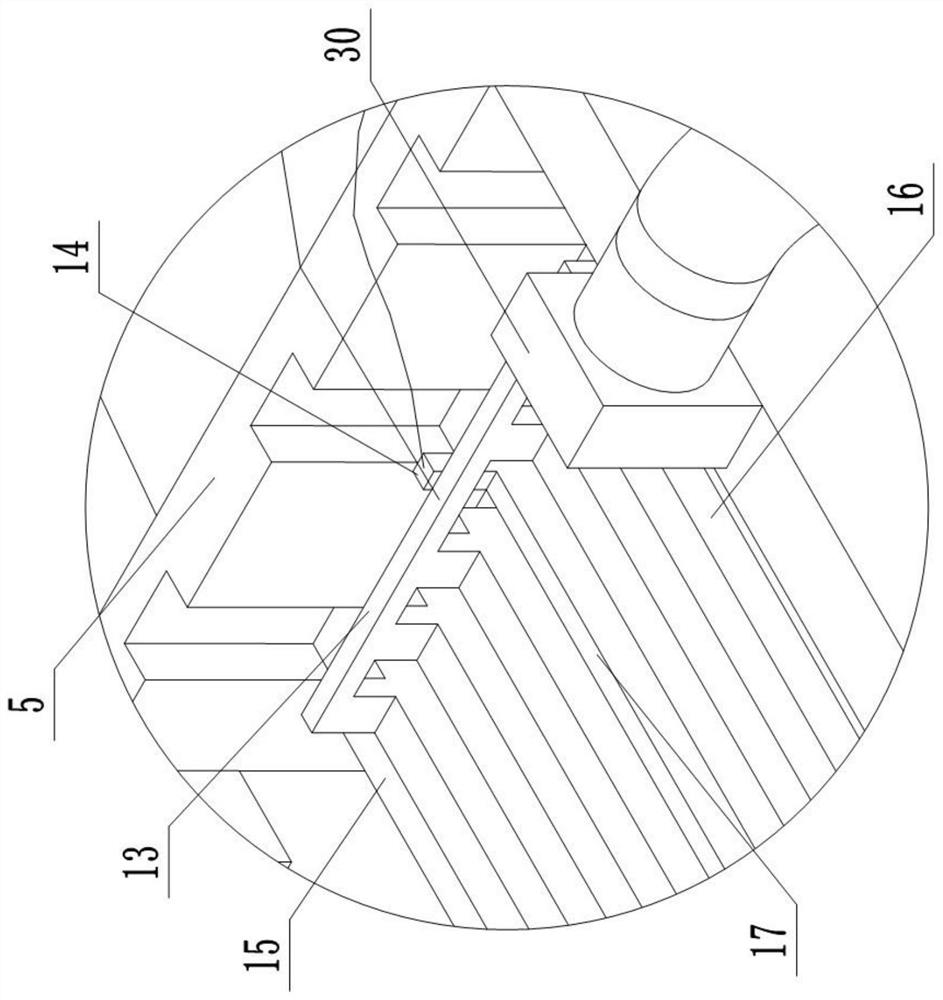

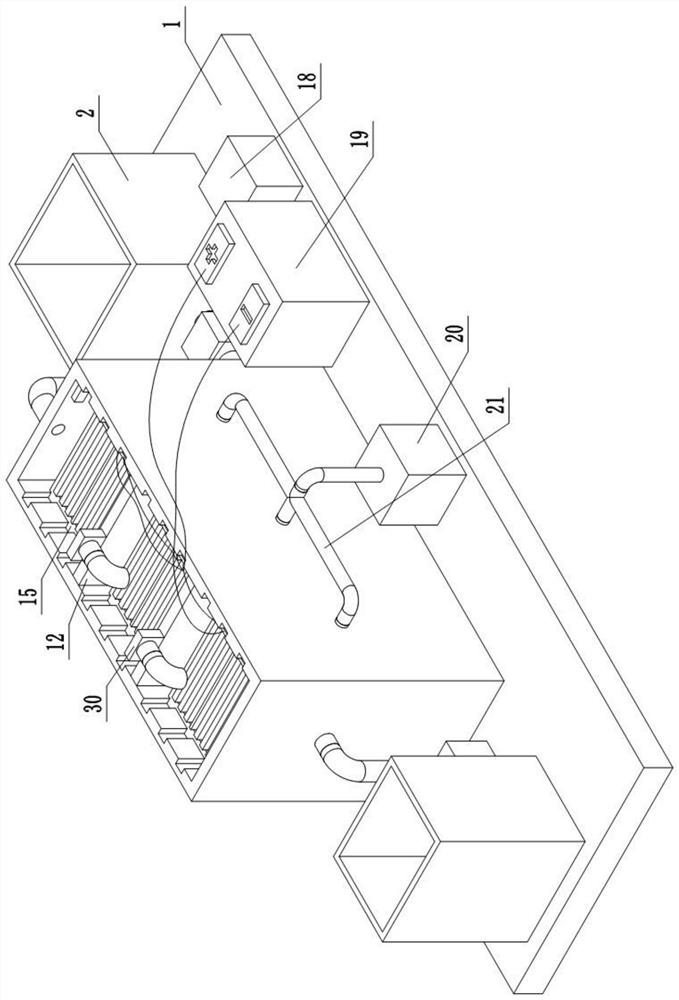

[0053] The specific embodiment: the first water pump 3 pumps sewage from the raw water pool 2 into the main reaction tank 5, the DC power supply 19 is turned on, and the cathode membrane 16 and the anode plate 17 are energized, and oxygen is pumped to the cathode membrane 16 by the aeration pump 20 , the aluminum plate releases Al 3+ The flocculant is generated in situ, and the impurities in the sewage are precipitated and deposited into the electrocoagulation settling tank 25. Since the main reaction tank 5 is divided into several secondary reaction tanks, and the top surface of the baffle plate 12 is located at the top surface of the main reaction tank 5 Below, the upper layer of clear water in the upper secondary reaction tank enters the lower secondary reaction tank to repeat the above sedimentation steps, the effect of sewage treatment is improved through multi-stage sedimentation, and the second water pump 10 pumps the treated sewage into the clean water storage tank 11 ...

Embodiment 1

[0057] Preparation of laboratory simulation wastewater: humic acid 20mg / L, kaolin 10mg / L, adding sodium chloride as background electrolyte. Use aluminum plate as anode, polypyrrole / copper / stainless steel mesh self-cleaning conductive film as cathode, the distance between the plates is 1cm, and the current density is 5A / m 2 , the initial pH of the simulated wastewater is 7, the effluent flux is 5L / h, and the removal rate of humic acid is investigated. When the reactor was running for 15 minutes, the removal rate of humic acid was 75.65%, after which the effluent quality remained stable.

Embodiment 2

[0059] Preparation of laboratory simulation wastewater: humic acid 20mg / L, kaolin 10mg / L, adding sodium chloride as background electrolyte. Use aluminum plate as anode, polypyrrole / copper / stainless steel mesh self-cleaning conductive film as cathode, the distance between the plates is 1cm, and the current density is 10A / m 2 , the initial pH of the simulated wastewater is 7, the effluent flux is 5L / h, and the removal rate of humic acid is investigated. With respect to embodiment one, when reaction runs 15min, the removal rate of humic acid is 81.47%, and this is due to having improved current density, the Al of anode dissolution 3+ As the amount increases, the hydroxyaluminum complexes also increase, thereby accelerating the removal rate of humic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com