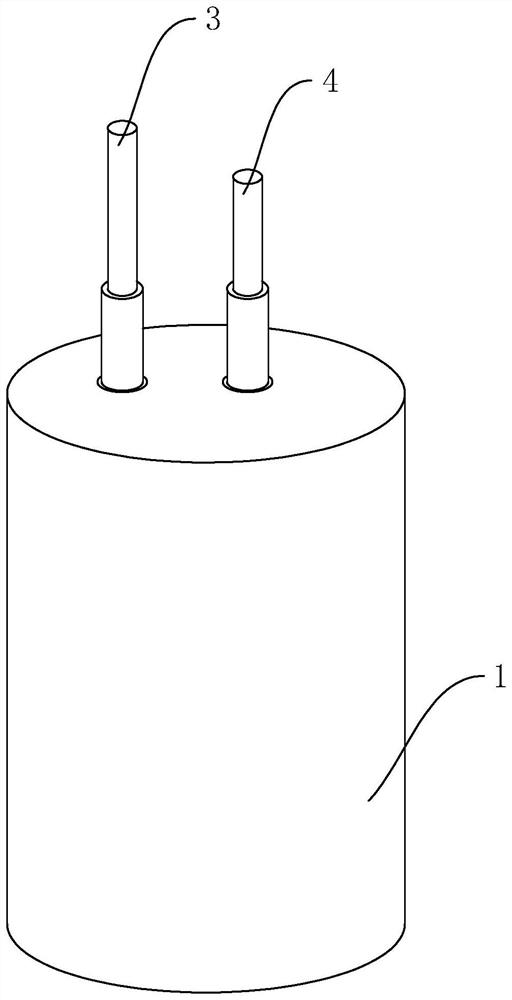

Electrode slurry for paper-based supercapacitor, paper-based electrode, preparation method and application

A supercapacitor and electrode slurry technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of poor adhesion between active electrode materials and paper substrates, difficulty in large-scale production, etc., and achieve production Low difficulty, stable conductivity, and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

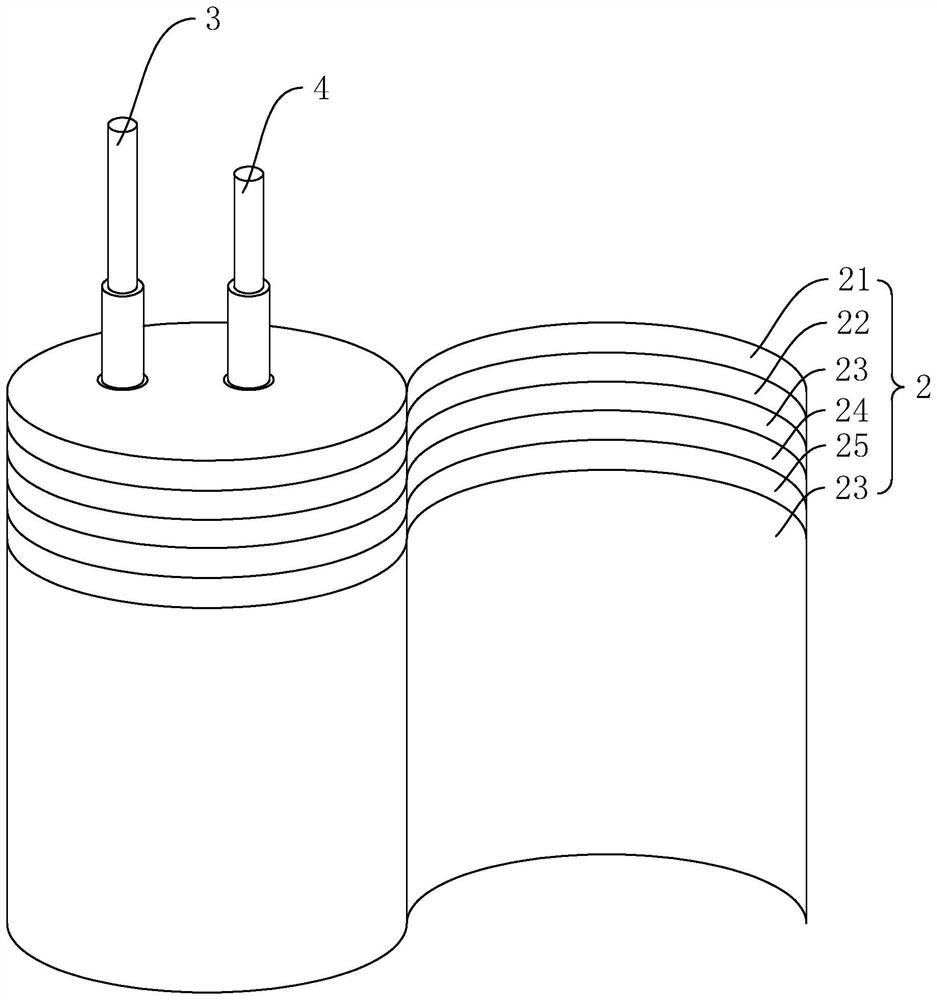

Method used

Image

Examples

Embodiment 1

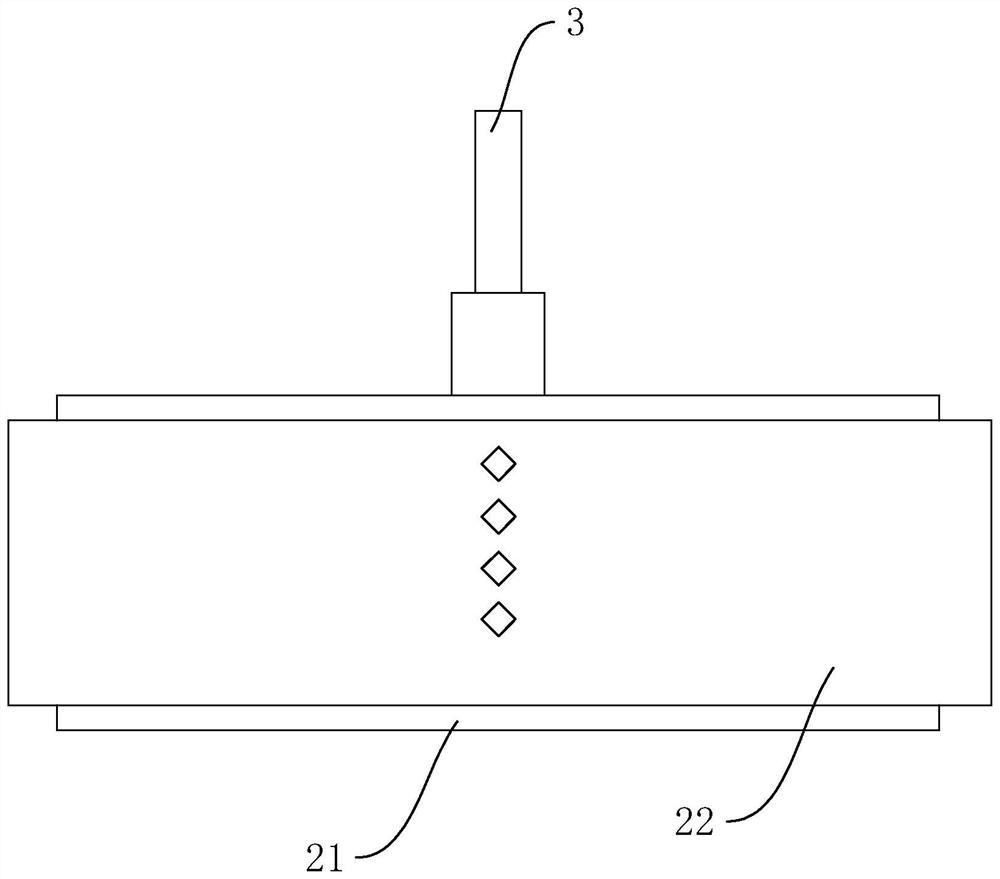

[0062] According to the percentage of weight, 85% of the porous activated carbon, 4.5% CMC cellulose, 2.5% alumina powder, 8% nickel powder added to a vacuum mixer mixed tank, rolling rotation for 60 minutes to obtain a mixture, The mixture is added to 1 to a cyclobutolane, and the slurry is introduced into the dispersion after 2 hours, and then the mixture is cleaned with a mixture of 0.5 times a cyclobutolane, and the cleaning liquid is introduced into the dispersion. The slurry in the dispersion machine was dispersed for 4 hours to obtain an electrode slurry.

[0063] In the slurry tank of the electrode slurry into the coating machine, the slurry tank uses 304 stainless steel material to prevent the introduction of other chemical impurities, and the electrode slurry is contaminated, and the electrode slurry in the slurry tank is continuously dispersed to prevent electrode slurry. The material is deposited or separated, and then the electrode slurry is evenly applied to the pape...

Embodiment 2

[0065] The difference from Embodiment 1 is that 87.5% porous activated carbon, 2.5% polyacrylic acid, 5% silicon nanoparticles, 5% micron silver powder are added to a vacuum mixer, rolling rotation mix. The mixture was obtained in 60 minutes, and N-methylpyrrolidone in the mixture was added to the mixing tank. After mixing for 2 hours, the slurry was introduced into the dispersion, and then the mixture was 0.5 times N-methylpyrrolidone. The mixing tank was cleaned and the cleaning liquid was introduced into the dispersion, and the slurry in the disperser was dispersed for 4 hours to obtain an electrode slurry.

Embodiment 3

[0067] The difference from Embodiment 1 is that 90% porous activated carbon, 2.5% polyvinyl alcohol, 2.5% zeolite powder, 5% silver nanowire, and 20% silver nanowires, rolling rotation The mixture was mixed for 60 minutes to obtain a mixture of 1.3 times gammutide in the mixing tank. After mixing for 2 hours, the slurry was introduced into the dispersion, and then the mixture was 0.5 times gamma. The ester washing the mixing tank and introduced the cleaning solution into the dispersion, dispersing the slurry in the disperser for 4 hours to obtain electrode slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com