High-gloss non-tinning coating of black bus bar and preparation method of black bus bar

A bus bar, black technology, which is applied in the field of high-gloss non-stick tin coating and the preparation of black bus bars, can solve the problems of unfavorable mass production, poor product performance, uneven coating thickness, etc. Excellent temperature performance effect, the effect of increasing the temperature of the welding head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

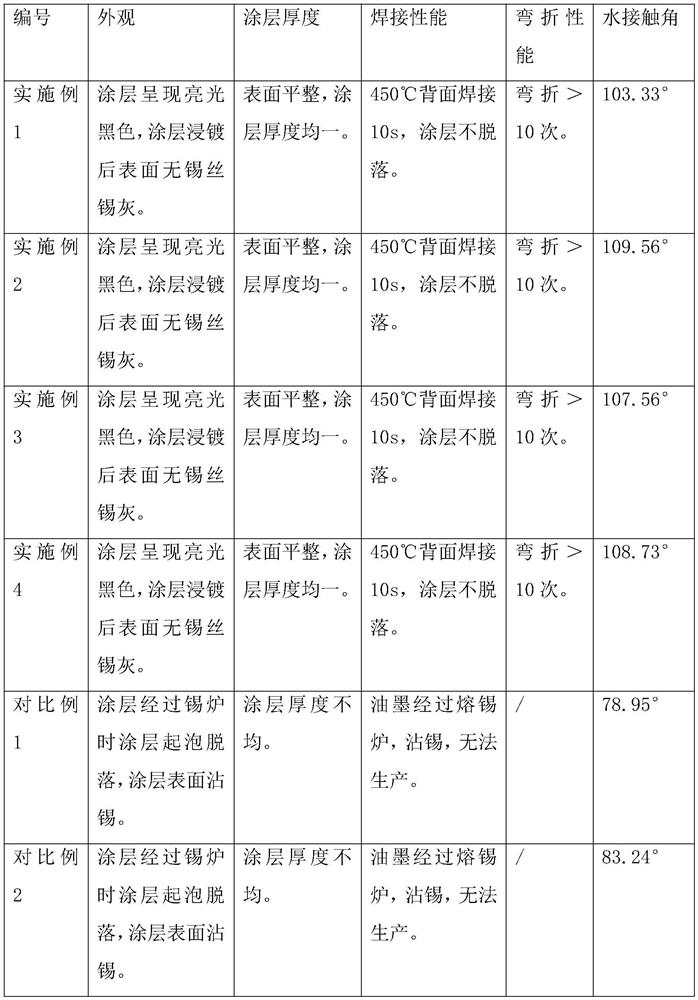

Examples

preparation example Construction

[0022] The embodiment of the present application discloses a preparation method of a high-gloss non-stick tin coating for a black bus bar, which includes the following components in parts by weight:

[0023] 25-30 parts of water-based polyhydroxy acrylic emulsion, 3-10 parts of fluorine-modified acrylic emulsion, 5-6 parts of carbon black, 5-10 parts of nano-sized titanium dioxide, 15-25 parts of isobutanol, diethylene glycol monobutyl ether 10-15 parts, 5-8 parts of water, 4-8 parts of water-based amino resin, 0.5-1 part of water-based leveling agent.

[0024] Put the above materials into the mixer and stir for 25-35min, the specific stirring time can be 25min, 30min, 35min, etc.

[0025] After stirring and mixing evenly, put it into a grinder for grinding. The grinding time is 1-3 hours to obtain a water-based low surface energy high-gloss ink slurry. The specific grinding time can be 1 hour, 2 hours, 3 hours, etc.

[0026] Specifically, the particle size range of nanoscale...

Embodiment 1

[0042] (1) Weigh 26 parts of water-based acrylic resin emulsion, 5 parts of fluorine-modified acrylic emulsion, 6 parts of carbon black, 5 parts of nano-scale titanium dioxide, 18 parts of isobutanol, 12 parts of diethylene glycol monobutyl ether, and 6 parts of water , Cytec 385 water-based amino resin 6 parts, BYK-333 leveling agent 0.5 parts. Add the above materials into the mixer and stir for 30min. After mixing evenly, grind with a grinder for 1 hour to obtain a water-based low surface energy high-gloss ink slurry.

[0043] (2) After the rolled copper strips have been degreased on the surface, they are arranged at equal intervals on the high-temperature-resistant silicone strips by a coating device. The number of copper strips is determined according to the width of the tape and the size of the copper strips. The distance between adjacent parallel copper strips is about 5mm. The coated copper strip is printed with high-gloss non-stick tin ink by the confluence belt coat...

Embodiment 2

[0045](1) Weigh 26 parts of water-based acrylic resin emulsion, 9 parts of fluorine-modified acrylic emulsion, 6 parts of carbon black, 5 parts of nano-scale titanium dioxide, 21 parts of isobutanol, 13 parts of diethylene glycol monobutyl ether, and 6 parts of water , Cytec 385 water-based amino resin 6 parts, BYK-333 leveling agent 0.8 parts. Add the above materials into the mixer and stir for 30min. After mixing evenly, grind with a grinder for 1 hour to obtain a water-based low surface energy high-gloss ink slurry.

[0046] (2) After the rolled copper strips have been degreased on the surface, they are arranged at equal intervals on the high-temperature-resistant silicone strips by a coating device. The number of copper strips is determined according to the width of the tape and the size of the copper strips. The distance between adjacent parallel copper strips is about 5mm. The coated copper strip is printed with high-gloss non-stick tin ink by the printing equipment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com