Cement cleaning agent and preparation and application methods thereof

A cleaning agent and cement technology, used in the field of cleaning agents, can solve the problems of serious wear on the surface of the material, incomplete removal, strong surface corrosion of the material, etc., and achieve the effect of good effect, good adaptability and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 15 parts of octadecyltrimethylammonium chloride in 961 parts of tap water, stir well and put in 24 parts of nano-magnesium hydroxide to prepare a suspension solution A; mix 240 parts of lactic acid, 260 parts of hypochlorous acid, 112 parts Diethyl ether and 8 parts of calcium oxalate were successively put into 380 parts of tap water and stirred until dissolved to obtain solution B. Put 12 parts of urea into 988 parts of tap water and stir until dissolved to obtain solution C.

Embodiment 2

[0029] Dissolve 26 parts of cetyltrimethylammonium chloride in 958 parts of tap water, stir evenly and put in 16 parts of nano-magnesium hydroxide to prepare a suspension solution A; 320 parts of acetic acid, 180 parts of carbonic acid, 98 parts of ethanol, 10 parts of ethylenediaminetetraacetic acid and 4 parts of iminodisuccinic acid were sequentially poured into 382 parts of tap water and stirred until dissolved to obtain solution B. Put 20 parts of urea into 980 parts of tap water and stir until dissolved to obtain solution C.

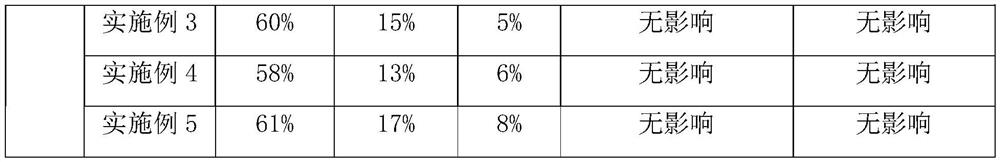

Embodiment 3

[0031] Dissolve 32 parts of dodecyltrimethylammonium chloride in 948 parts of tap water, stir well and then drop into 20 parts of nano-magnesium hydroxide to prepare a suspension solution A; mix 280 parts of salicylic acid, 220 parts of phosphoric acid, 127 parts Ethylene glycol, 6 parts of carboxymethyl chitosan, and 6 parts of sodium ethylenediaminetetramethylene phosphate were successively put into 361 parts of tap water and stirred until dissolved to obtain solution B. Put 20 parts of urea into 980 parts of tap water and stir until dissolved to obtain solution C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com