Tin plating and tin removing solution formula and process for plating tin on surface of part

A technology of tin plating solution and formula, which is applied in the field of tin plating and tin removal solution formula and technology, to achieve the effects of improving cathodic polarization and dispersing ability, facilitating operation, and improving coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

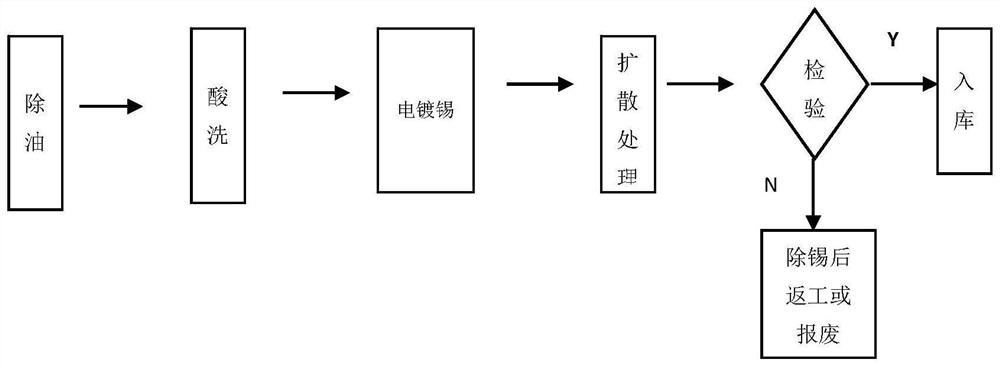

Method used

Image

Examples

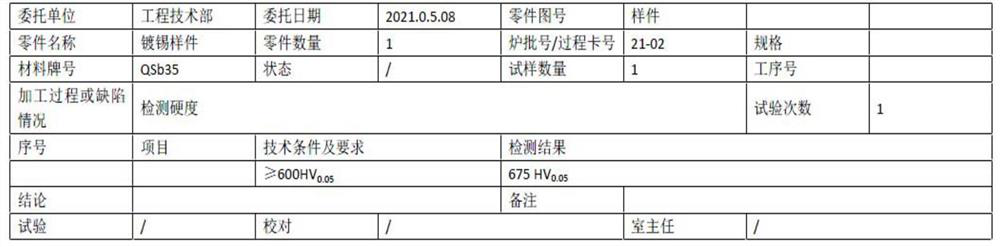

Embodiment 1

[0030] In this embodiment, the material is electroplated tin on the surface of copper alloy parts of QSb3.5, and the tin plating solution adopted includes the sulfuric acid that the concentration is 45g / L stannous sulfate, 80g / L, gelatin 2g / L, 8g / L tin Phenol, 0.4g / L nickel sulfate. The tin removal solution used included 180g / L sodium hydroxide, 70g / L sodium m-nitrobenzenesulfonate, 40g / L lead acetate, 15g / L sodium citrate, and 1.5mL / L polyethylene glycol. The above-mentioned concentration data all refer to the mass of each substance in every liter of water, such as stannous sulfate with a concentration of 45g / L means that every liter of water contains 45g of stannous sulfate.

[0031] Tin-plate its surface by the following steps:

[0032] First, wash the parts with a neutral degreasing solution (okatite90);

[0033] Secondly, hang the cleaned parts and use CrO 3 : 50-60g / L, H 2 SO 4 : 200-220g / L solution, at a temperature of 40-60°C, for 3-5 minutes for photochemical tre...

Embodiment 2

[0041]Different from Example 1, the tin plating solution used in this example includes the concentration of 40g / L of stannous sulfate, 100g / L of sulfuric acid, 1g / L of gelatin, 5g / L of phenol, 0.5g / L nickel sulfate. The tin removal solution used included 150g / L sodium hydroxide, 80g / L sodium m-nitrobenzenesulfonate, 30g / L lead acetate, 10g / L sodium citrate, and 2.0mL / L polyethylene glycol.

[0042] Tin-plate its surface by the following steps:

[0043] First, wash the parts with a neutral degreasing solution (okatite90);

[0044] Secondly, hang the cleaned parts and use CrO 3 : 50-60g / L, H 2 SO 4 : 200-220g / L solution, at a temperature of 40-60°C, for 3-5 minutes for photochemical treatment;

[0045] After that, the actinized parts are electroplated in the above tin plating solution at a temperature of 38°C; the current density is 2A / dm 2 ; The time is 40 minutes. After tin plating, check that the appearance of the coating is uniform, meticulous and continuous. The thic...

Embodiment 3

[0052] Different from Example 1, the tin-plating solution used in this example includes a concentration of 50g / L stannous sulfate, 60g / L sulfuric acid, 3g / L gelatin, 10g / L phenol, 0.2g / L nickel sulfate. The tin removal solution used included 200g / L sodium hydroxide, 60g / L sodium m-nitrobenzenesulfonate, 50g / L lead acetate, 20g / L sodium citrate, and 1.0mL / L polyethylene glycol.

[0053] Tin-plate its surface by the following steps:

[0054] First, wash the parts with a neutral degreasing solution (okatite90);

[0055] Secondly, hang the cleaned parts and use CrO 3 : 50-60g / L, H 2 SO 4 : 200-220g / L solution, at a temperature of 40-60°C, for 3-5 minutes for photochemical treatment;

[0056] After that, the actinized parts are electroplated in the above tin plating solution at a temperature of 20°C; the current density is 5A / dm 2 ; The time is 50 minutes. After tin plating, check that the appearance of the coating is uniform, meticulous and continuous. The thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com