Antibacterial fiber as well as preparation method and application thereof

A technology of antibacterial fibers and composite materials, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of poor spinning performance of antibacterial fibers and graphene agglomeration, and achieve excellent antibacterial performance, easy operation, and surface Smooth and flat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

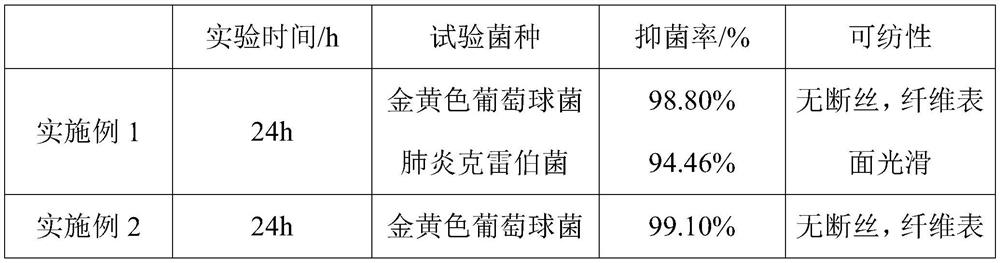

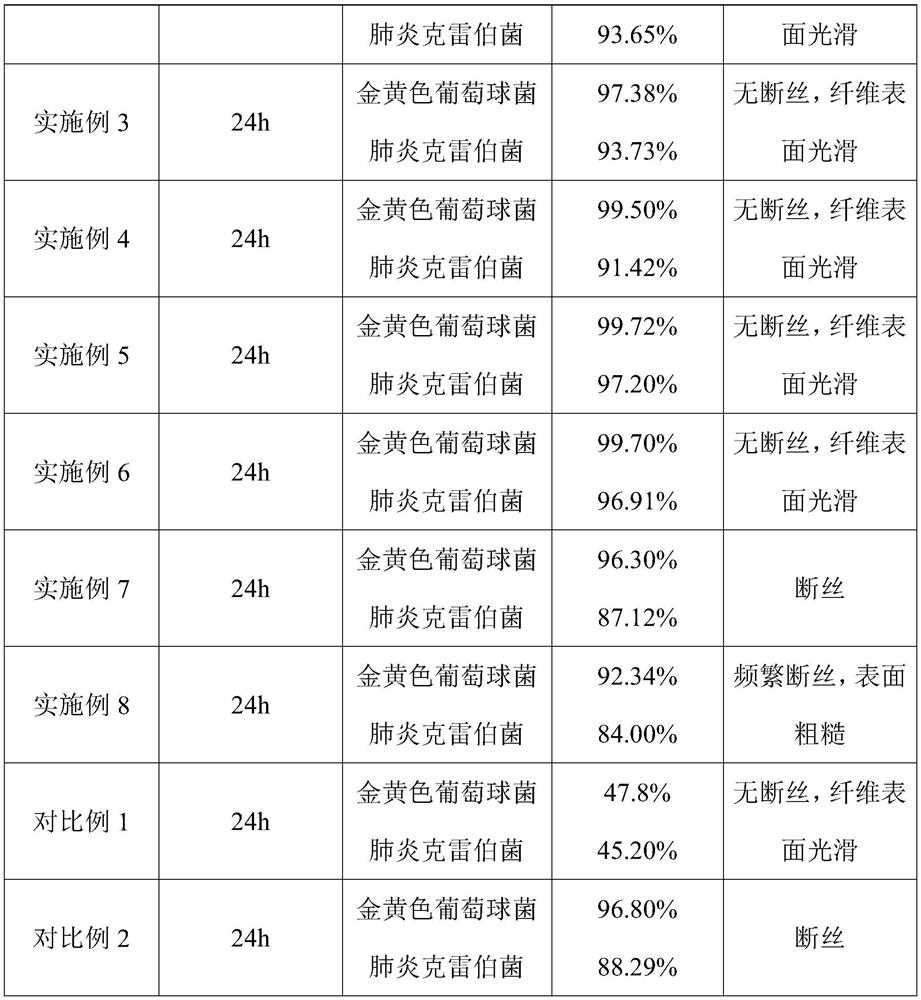

Examples

preparation example Construction

[0052] Preparation of graphene oxide composite material A

[0053] 60mg of graphene oxide microchips were dispersed in 30ml of absolute ethanol, and supersonicated for 1h to make a suspension; under stirring, 0.42g of tetrabutyl titanate (the mass ratio of titanium in graphene oxide to tetrabutyl titanate) 1:1) slowly drop into the suspension, add 5ml of glycerol, stir evenly, move the mixed solution into a hydrothermal reaction kettle, put the reaction kettle into a blast drying oven at 180°C for 8 hours of heat preservation, After the reaction was over, the reactor was taken out and placed at room temperature to allow it to cool down naturally. After suction filtration, the obtained product was washed twice with ethanol, and then washed twice with deionized water, and the filter cake was placed in a freeze dryer at -50°C for 24 hours to obtain nanorod-shaped titanium dioxide / graphene oxide microsheet graphene oxide Composite material, wherein the average particle diameter o...

Embodiment 1

[0061] The present embodiment provides a kind of preparation method of antibacterial fiber, and described preparation method comprises:

[0062] After 998g PTT slices were dried under vacuum at 100°C for 12h to remove moisture, they were mixed with the graphene oxide composite material A of 2g nanorod-shaped titanium dioxide / graphene oxide microflakes (graphene oxide microflakes accounted for 0.2wt% of the total mass of the antibacterial fiber), and then Twin-screw extruder blends, extrudes, and granulates to make fiber resin slices containing nanorod-shaped titanium dioxide / graphene microflake graphene oxide composite materials; place the slices in an oven for 6 hours at 100°C for vacuum drying, and then melt Spinning to produce antibacterial fibers.

[0063] Among them, the heating temperature of the first zone to the ninth zone of the twin-screw extruder is respectively: the temperature of the first zone is 230°C, the temperature of the second zone is 230°C, the temperature...

Embodiment 2

[0066] This embodiment provides a preparation method of an antibacterial fiber. The preparation method is the same as that of Embodiment 1 except that the graphene oxide composite material A is replaced by the graphene oxide composite material B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com