Composite material as well as preparation method and application thereof

A technology of composite materials and transfer method, which is applied in the field of composite materials and its preparation, can solve the problem of the need to improve the life of carriers, and achieve the effects of low cost, prolonging the life of carriers, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of composite material, its preparation method comprises the steps:

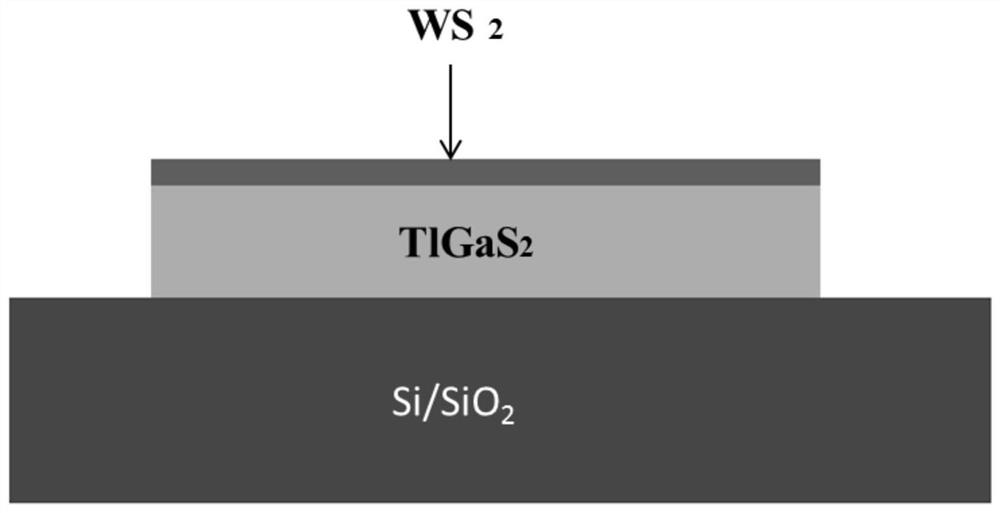

[0032] First, thallium gallium sulfide (TlGaS 2 ) and monolayer tungsten disulfide (WS 2 ), and then firstly transfer GaS-Tl nanosheets to Si / SiO by micromanipulating the transfer platform 2 (300nm) on the substrate, then transfer a single layer of tungsten disulfide in the same way and make it overlap with gallium thallium sulfide on the substrate at least partially to form a heterogeneous structure to obtain a composite material (the structure of the composite material is as follows figure 1 shown).

Embodiment 2

[0034] An optoelectronic device comprising the composite material prepared in Example 1, said optoelectronic device comprising: light-emitting diodes, laser diodes, photodetectors, avalanche photodiodes, cascode switches, transistors, rectifiers and thyristors, high electron mobility Power Transistor, Metal Semiconductor Field Effect Transistor, Metal Oxide Field Effect Transistor, Power Metal Oxide Semiconductor Field Effect Transistor, Power Metal Insulator Semiconductor Field Effect Transistor, Bipolar Junction Transistor, Metal Insulator Field Effect Transistor, Heterojunction Bipolar Transistor , a power insulated gate bipolar transistor, a power vertical junction field effect transistor, an infrared photodetector or a combination thereof, wherein the composite material constitutes a heterojunction in the optoelectronic device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com