Silicon carbon-graphite negative electrode material and preparation method and application thereof

A graphite negative electrode and silicon carbon technology, which is applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of easy agglomeration of silicon particles, capacity attenuation, and inability to use graphite composites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

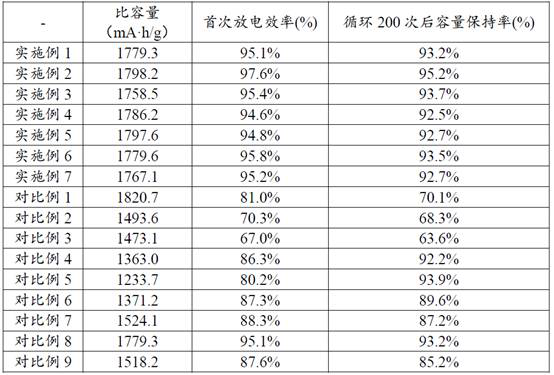

Examples

Embodiment 1

[0094] This embodiment is a method for preparing a silicon carbon-graphite negative electrode material, comprising the following steps:

[0095] S1: Add 1g of carbon fiber (Beijing Deke Daojin Technology Co., Ltd., VGCF150nm-200nm carbon nanofiber) to 100g of potassium chlorate and sulfuric acid mixed solution (the mass fraction of potassium chlorate is 5%, the mass fraction of sulfuric acid is 15%), at 65 Stir and react at ℃ for 1 h. After the reaction is completed, filter and rinse with deionized water for 5 times to obtain carbon oxide fibers.

[0096] Graphite particles (G810738, Shanghai Macklin Biochemical Technology Co., Ltd., about 11 μm) were calcined for 1.5 h in an ammonia atmosphere at a temperature of 800 ° C to obtain nitrogen-doped graphite particles (the nitrogen doping content was measured by an elemental analyzer to be 0.8%).

[0097] Add nitrogen-doped graphite particles and carbon oxide fibers to water (mass ratio of nitrogen-doped graphite particles, surf...

Embodiment 2

[0119] This example is a method for preparing a silicon carbon-graphite negative electrode material, and the difference from Example 1 is that the deposition time of titanium nitride in this example is 80s.

[0120] The difference between the carbon silicon-graphite negative electrode material prepared in this embodiment and Example 1 is:

[0121] The thickness of the zirconium nitride layer is 15 nm to 20 nm.

Embodiment 3

[0123] This example is a method for preparing a silicon carbon-graphite negative electrode material, and the difference from Example 1 is that the deposition time of titanium nitride in this example is 60s.

[0124] The difference between the carbon silicon-graphite negative electrode material prepared in this embodiment and Example 1 is:

[0125] The thickness of the zirconium nitride layer is 10 nm to 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com