Light-activated antibacterial dressing and preparation method thereof

A light-activated, heterojunction technology, applied in the direction of antibacterial drugs, pharmaceutical formulations, inorganic active ingredients, etc., can solve the problem of non-existence of antibacterial effect, achieve excellent antibacterial effect, high feasibility, and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the above-mentioned wound dressing for treating infected wounds, the method comprising the following steps:

[0042] S1. Etching MAX ceramics into MXene nanosheets.

[0043] Specifically, S11. First, immerse the MAX ceramic raw material in the etching solution, and keep stirring for 12-24 hours at a constant temperature of 37-45°C.

[0044] Wherein, the etching solution may be a mixture of lithium fluoride and hydrochloric acid solution. But the present invention is not limited thereto, and the direct product hydrofluoric acid can also be used. Compared with the use of finished hydrofluoric acid, this embodiment prepares the mixture of lithium fluoride and hydrochloric acid solution as the etching solution, which can avoid the transfer and dumping of hydrofluoric acid, which is safer and reduces the possibility of danger. sex.

[0045] MXene material is a new type of two-dimensional layered transition metal c...

example 1

[0100] Will 1gMAX(Ti 3 AlC 2 ) was immersed in an etching solution, which was a mixture of lithium fluoride (LiF, 1 g) and hydrochloric acid (HCl) solution (9M, 20 mL), and kept stirring at a constant temperature of 40° C. for 12 hours. Then, wash the precipitate with deionized water, centrifuge 7 times at 3500r / min, and the centrifugation time is 5min, 15min, 30min, 1h, 1h respectively. The sixth and seventh centrifugation was repeated for 1 h. The product was lyophilized at -20 °C to obtain etched MXene.

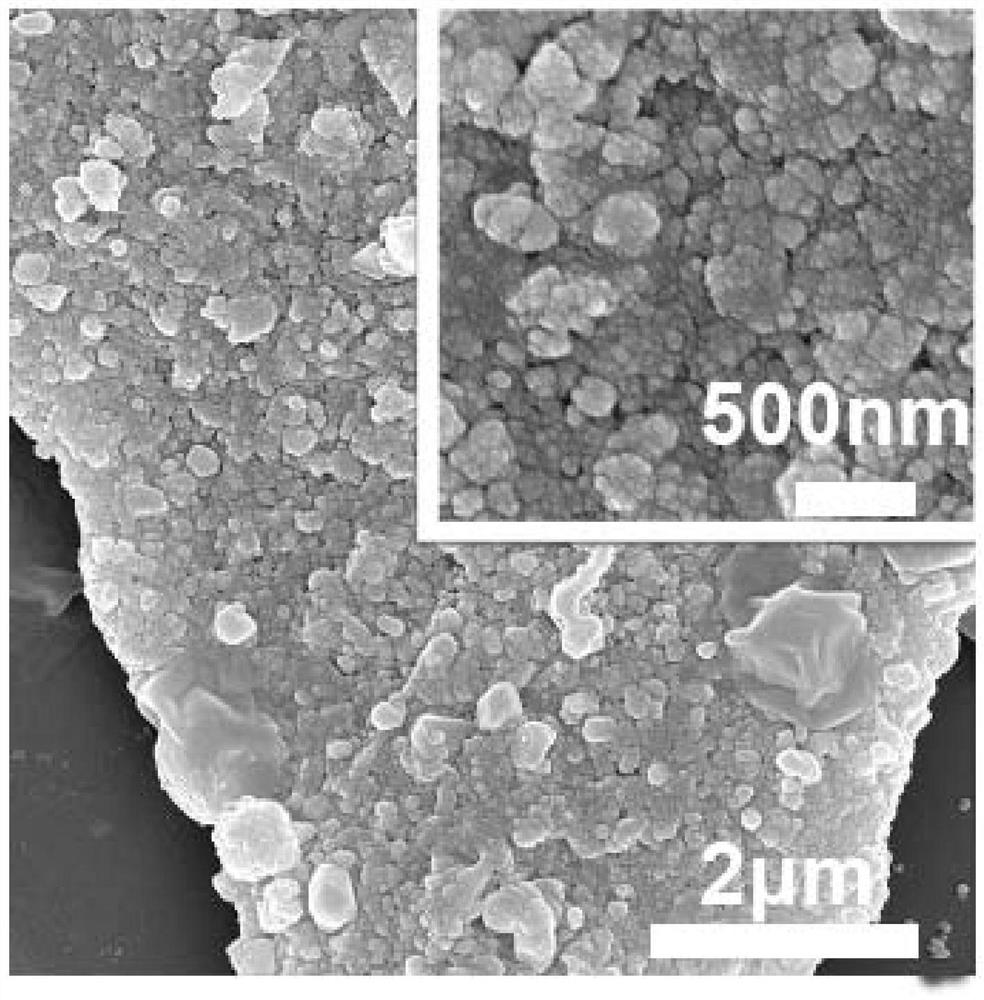

[0101] The MXene (0.1 g) obtained above was dispersed in distilled water, and 0.1 M silver nitrate (AgNO 3 ) solution 100mL, make Ag + Electrostatic adsorption on the surface of MXene. The resulting product was dialyzed overnight until the dialysate was free of Ag + For residues, check with sodium chloride. Then vigorously stir in the dialysate, and gradually add 0.05M silver phosphite (Na 2 HPO 4 ) aqueous solution. The precipitate was freeze-dried again to obta...

example 2

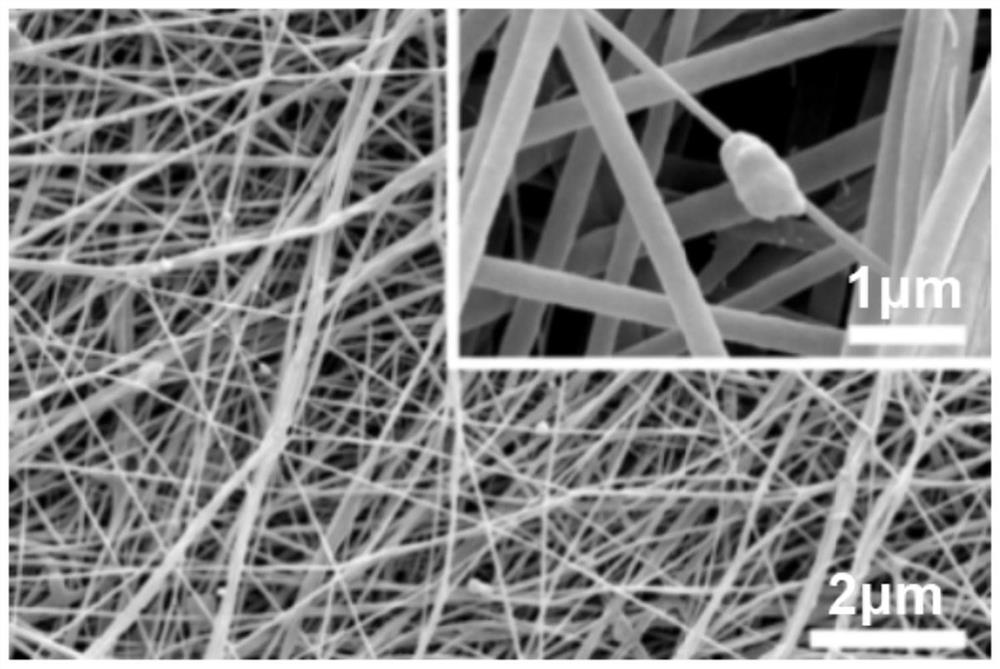

[0106] Will 1gMAX(Ti 3 AlC 2 ) was immersed in an etching solution, which was a mixture of lithium fluoride (LiF, 1 g) and hydrochloric acid (HCl) solution (9M, 20 mL), and kept stirring at a constant temperature of 40° C. for 12 hours. Then, wash the precipitate with deionized water, centrifuge 7 times at 4000r / min, the centrifugation time is 5min, 15min, 30min, 1h, 1h; repeat the sixth and seventh centrifugation for 1h. The product was lyophilized in a vacuum lyophilizer to obtain etched MXene.

[0107] The MXene (0.15g) obtained above was dispersed in distilled water, and 0.15M silver nitrate (AgNO 3 ) solution 100mL, make Ag + Electrostatic adsorption on the surface of MXene. The resulting product was dialyzed overnight until the dialysate was free of Ag + For residues, check with sodium chloride. Then vigorously stir in the dialysate, and gradually add 0.075M silver phosphite (Na 2 HPO 4 ) aqueous solution. The precipitate was freeze-dried again to obtain the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com