Modified bismaleimide carbon fiber prepreg, composite material and preparation method thereof

A bismaleimide carbon fiber and bismaleimide technology, which is applied in the field of polymer composite materials, can solve problems such as difficulty in forming, and achieve the effects of good processability, long pot life and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of high temperature resistance, modified bismaleimide carbon fiber prepreg:

[0029] Step 1. Preparation of high temperature resistant, modified bismaleimide prepreg

[0030] Weigh and stir 4,4-bismaleimidodiphenylmethane and diallyl bisphenol A at a ratio of 2:1 by mass and number, and then further fully mix the above two by grinding;

[0031] Heating the ground components at a heating temperature of 145°C and reacting for 4 hours to obtain a prepolymer;

[0032] After prepolymerization, lower the temperature to 90°C, add bisphenol A cyanate, and continue polymerization for 20 minutes to obtain a high temperature resistant, modified bismaleimide prepreg.

[0033] Step 2. Preparation of high temperature resistant, modified bismaleimide carbon fiber prepreg

[0034] Use the high temperature resistant and modified bismaleimide prepreg obtained in step 1 to process into a film. The preparation process is: preheat the bismaleimide prepreg at 8...

Embodiment 2

[0037] The high temperature resistant, modified bismaleimide carbon fiber prepreg obtained in Example 1 is cut and laid, and then according to (130±5)°C / 2h±5min+(180±5)°C / 1h±5min+ (240±5)°C / 3h±5min gradient temperature rise, mold clamping pressure controlled at 2MPa for curing, high temperature resistant, modified bismaleimide carbon fiber composite material was obtained.

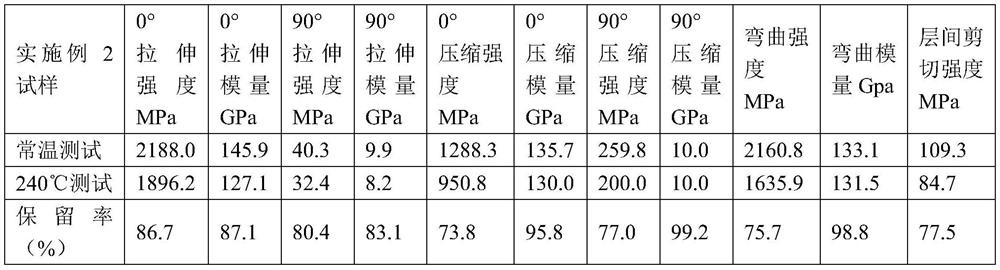

[0038] The high temperature resistant bismaleimide carbon fiber composite material prepared in Example 2 was subjected to mechanical tests at room temperature and high temperature (240° C.) using a universal testing machine. The test results are shown in Table 1. In the test, the tensile strength adopts GB / T 3354-2014, the compressive strength adopts GB / T 3856-2005, the flexural strength adopts GB / T 3356-1999, and the interlaminar shear strength adopts JC / T 773-1996.

[0039] Table 1

[0040]

[0041] As can be seen from Table 1, the tensile properties, compressive properties, flexural properties, and i...

Embodiment 3

[0043] A kind of preparation method of high temperature resistance, modified bismaleimide carbon fiber prepreg:

[0044] Step 1. Preparation of high temperature resistant, modified bismaleimide prepreg

[0045] Weigh and stir 4,4-bismaleimidodiphenylmethane and diallyl bisphenol S at a ratio of 2:1 in parts by mass, and then further thoroughly mix the above two by grinding;

[0046] Heat the ground components at a temperature of 130°C and react for 5 hours to obtain a prepolymer;

[0047] After prepolymerization, lower the temperature to 80°C, add bisphenol A cyanate, and continue polymerization for 30 minutes to obtain a high temperature resistant, modified bismaleimide prepreg.

[0048] Step 2. Preparation of high temperature resistant, modified bismaleimide carbon fiber prepreg

[0049]Use the high temperature resistant and modified bismaleimide prepreg obtained in step 1 to process into a film. The preparation process is: preheat the bismaleimide prepreg at 75°C for 36 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com