High-weather-resistance anti-skid foaming shoe sole and preparation method thereof

The technology of weather resistance and foaming agent is applied in the field of high weather resistance anti-skid foamed sole and its preparation field, which can solve the problems of corrosion resistance, poor weather resistance, insufficient tensile strength, poor wear resistance, etc., so as to improve the weather resistance and The effect of anti-skid performance, energy consumption reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for a highly weather-resistant non-slip rubber foam sole, comprising the following steps:

[0030] Step 1: Mix the raw materials other than the foaming agent, vulcanizing agent, accelerator, and stabilizer by weight, and then carry out banburying. After adjusting the temperature to 95°C, heat it for 5 minutes and then turn the material for the first time; continue to heat up to 102 °C, turn the material for the second time; continue to heat up to 108 °C, add foaming agent, vulcanizing agent, accelerator and stabilizer, turn the material for the third time, and pour the material after banburying for 5 minutes to obtain a blend;

[0031] Step 2: Thin the blend on a roller machine until the roller spacing is 1.2mm, and the number of thinning times is 3 times, then adjust the roller spacing to 5mm to produce a sheet, and transport it to the granulator for granulation. Eagerly cut out pellets to obtain foam pellets;

[0032] Step 3, according to the vul...

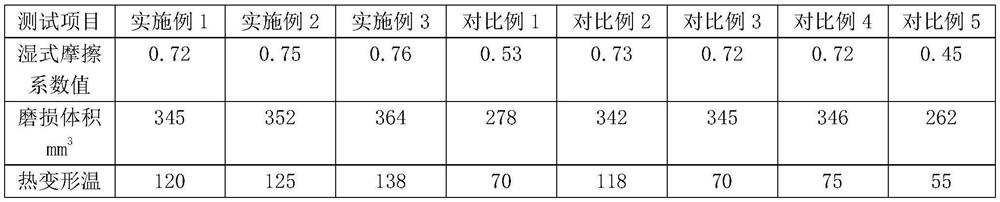

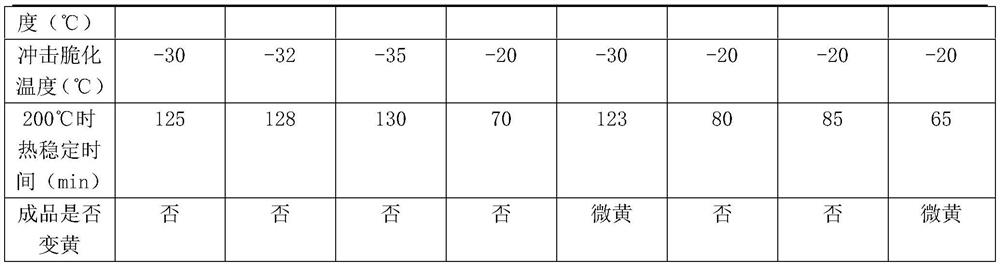

Embodiment 1

[0037] A kind of antiskid rubber foam sole with high weather resistance, its raw material composition is as shown in table 1, and wherein, stabilizer is by the ratio of epoxidized soybean oil, zinc ricinoleate, calcium stearate by mass ratio 1:0.4:0.3 Composition; the foaming agent is composed of p-toluenesulfonyl hydrazide and sodium bicarbonate in a mass ratio of 1:0.6; the accelerator is composed of benzoic acid, ethylenediamine, and stearic acid in a weight ratio of 1:1:0.8.

[0038] Its preparation method comprises the following steps:

[0039] Step 1: Mix the raw materials other than the foaming agent, vulcanizing agent, accelerator, and stabilizer by weight, and then carry out banburying. After adjusting the temperature to 95°C, heat it for 5 minutes and then turn the material for the first time; continue to heat up to 102 °C, turn the material for the second time; continue to heat up to 108 °C, add foaming agent, vulcanizing agent, accelerator and stabilizer, turn the ...

Embodiment 2

[0043] A kind of antiskid rubber foam sole with high weather resistance, its raw material composition is as shown in table 1, wherein, stabilizer is made of epoxy soybean oil, zinc ricinoleate, calcium stearate in the ratio of 1:0.7:0.7 by mass Composition; the foaming agent is composed of p-toluenesulfonyl hydrazide and sodium bicarbonate in a mass ratio of 1:0.8; the accelerator is composed of benzoic acid, ethylenediamine, and stearic acid in a weight ratio of 1:1.5:0.6.

[0044] Its preparation method comprises the following steps:

[0045] Step 1: Mix the raw materials other than the foaming agent, vulcanizing agent, accelerator, and stabilizer by weight, and then carry out banburying. After adjusting the temperature to 95°C, heat it for 5 minutes and then turn the material for the first time; continue to heat up to 102 °C, turn the material for the second time; continue to heat up to 108 °C, add foaming agent, vulcanizing agent, accelerator and stabilizer, turn the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com