Engineering yeast strain with high yield of hyaluronidase and application of engineering yeast strain

A technology of hyaluronidase and yeast strain, applied in the field of genetic engineering, can solve the problems of high price and low level of recombinant expression, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

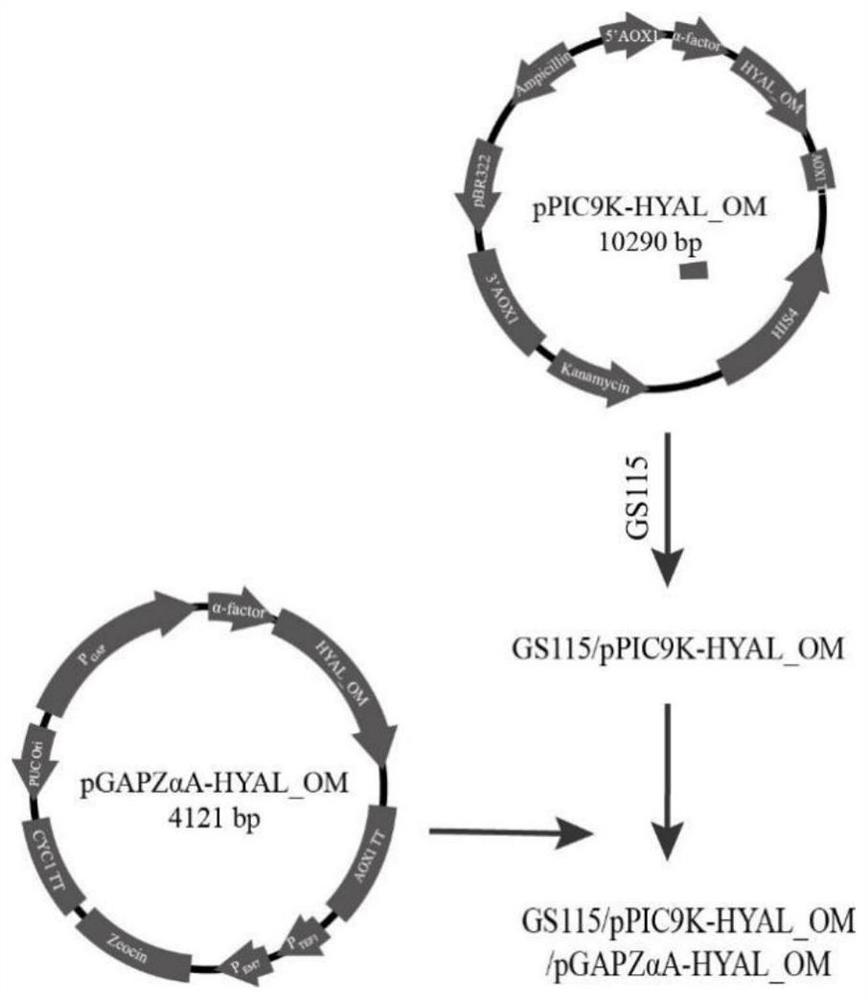

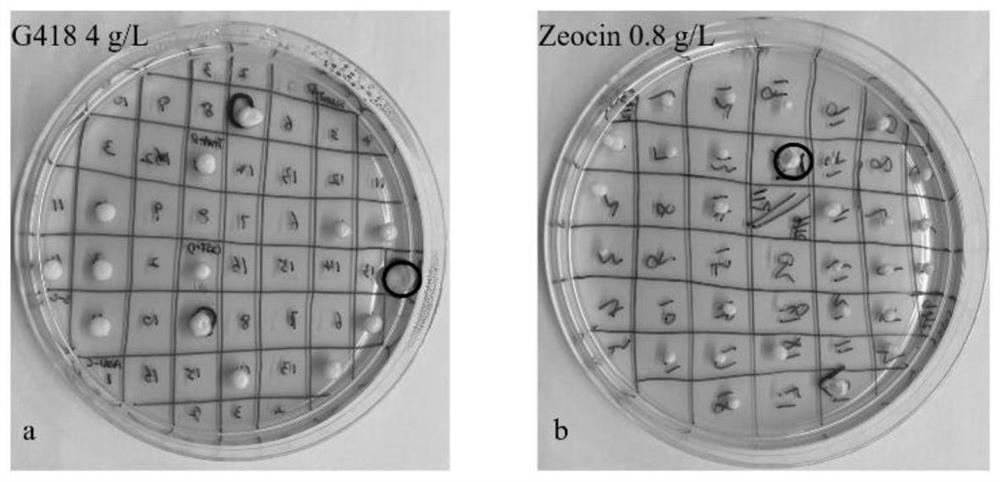

[0067] The construction of the engineering yeast strain of embodiment 1 high-yielding hyaluronidase

[0068] Based on the full-length gene sequence (Genbank: FX985505.1) of the hyaluronidase from the NCBI database, the codons were optimized according to the codon preference of Pichia pastoris. The gene sequence of the codon-optimized hyaluronidase from Pichia chinensis is shown in SEQ ID NO.2, which was synthesized by Nanjing GenScript Biotechnology Co., Ltd. and cloned into EcoRI and NotI of Pichia pastoris expression vector pPIC9K Between the restriction sites, the recombinant expression vector pPIC9K-HYAL_OM was obtained opt .

[0069] Take pPIC9K-HYAL_OM opt The recombinant expression vector is used as a template,

[0070] Primers are designed to cut off a signal peptide sequence at the N-terminal of the full-length hyaluronan hydrolase gene to obtain a genetically engineered hyaluronan hydrolase gene fragment, the sequence of which is shown in SEQ ID NO.1.

[0071] Wh...

Embodiment 2

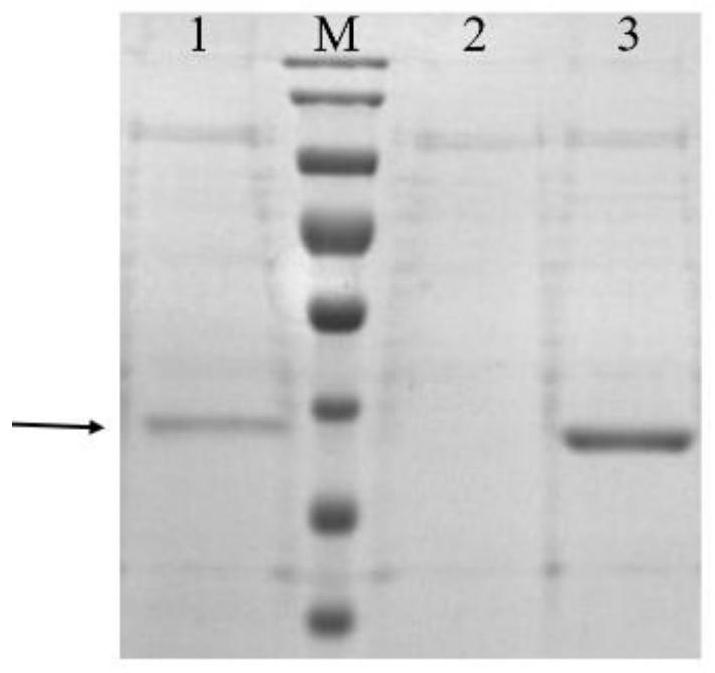

[0075] Embodiment 2 Recombinant Hyaluronidase Engineering Yeast Strain Shake Flask Fermentation

[0076] For the obtained recombinant engineering bacteria P.pastoris GS115 / pPIC9K-ΔN24HYAL_OM opt / pGAPZαA-ΔN24HYAL_OM opt Shake flask fermentation was carried out.

[0077] The pure glycerol culture and fermentation steps are as follows: pick a single clone and inoculate it in 40 mL of YPD medium (yeast extract 10 g / L, peptone 20 g / L, glucose 20 g / L), and culture at 30°C and 200 rpm for 24 hours. Transfer to 40mL expression medium BMGYS (yeast extract 10g / L, peptone 20g / L, K 2 HPO 4 3g / L, KH 2 PO 4 11.8g / L, YNB 3.4g / L, ammonium sulfate 10g / L, biotin 4×10 -4 g / L, glycerol 40g / L), 30°C, 200rpm for 96h.

[0078] The methanol-induced fermentation steps are as follows: a single clone was picked and inoculated in 40 mL of YPD medium, and cultured at 30° C. and 200 rpm for 24 hours. Transfer to 40mL initial expression medium BMGY (yeast extract 10g / L, peptone 20g / L, K 2 HPO ...

Embodiment 3

[0081] Example 3 Recombinant Hyaluronidase Engineering Yeast Strain 5-L Fermentor High Density Cultivation (Using Methanol as Carbon Source)

[0082] The combined strain P. pastoris GS115 / pPIC9K-ΔN24HYAL_OM opt / pGAPZαA-ΔN24HYAL_OM opt Carry out high density culture in 5-L fermenter.

[0083] Inoculate a single colony on the YPD plate into 50mL YPD liquid medium, culture at 30°C 220rpm for 24h, inoculate the culture solution at 10% into 200mL BMGY medium, culture at 30°C 220rpm for 24h; inoculate 200mL seed liquid cultivated for 24h to containing 2L BSM fermentation medium (glycerol 40g / L, K 2 SO 4 18g / L, KOH 4.13g / L, 85%H 3 PO 4 26.7mL / L, CaSO 4 2H 2 O 0.93g / L, MgSO 4 ·7H 2 O 14.9g / L, 4.4mL / L filter-sterilized PTM1; PTM1 formulation: CuSO 4 ·5H 2 O 6g / L, KI 0.09g / L, MnSO 4 ·H 2 O 3g / L, H 3 BO 3 0.02g / L, MoNa 2 o 4 2H 2 O 0.2g / L, CoCl 2 ·6H 2 O 0.92g / L, ZnCl 2 20g / L, FeSO 4 ·7H 2 O 65g / L, biotin 0.2g / L, H 2 SO 4 5.0mL) in a 5-L fermenter.

[0084...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com