Special compound fertilizer for wheat as well as preparation process and granulation equipment of special compound fertilizer

A technology of preparation process and granulation equipment, which is applied in the field of compound fertilizer production, can solve the problems of particle size including inconsistency, reduce the quality of compound fertilizer granulation products, etc., and achieve the effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] see figure 1 , the present invention provides the following scheme: a special compound fertilizer for wheat, comprising the following components in parts by weight: 14 parts of potassium chloride, 24 parts of monoammonium phosphate, 17 parts of ammonium chloride, 35 parts of urea, 1 part of polyglutamic acid 1.5 parts of borax, 2 parts of zinc sulfate, 5 parts of loss control agent, and 1 part of anti-caking agent.

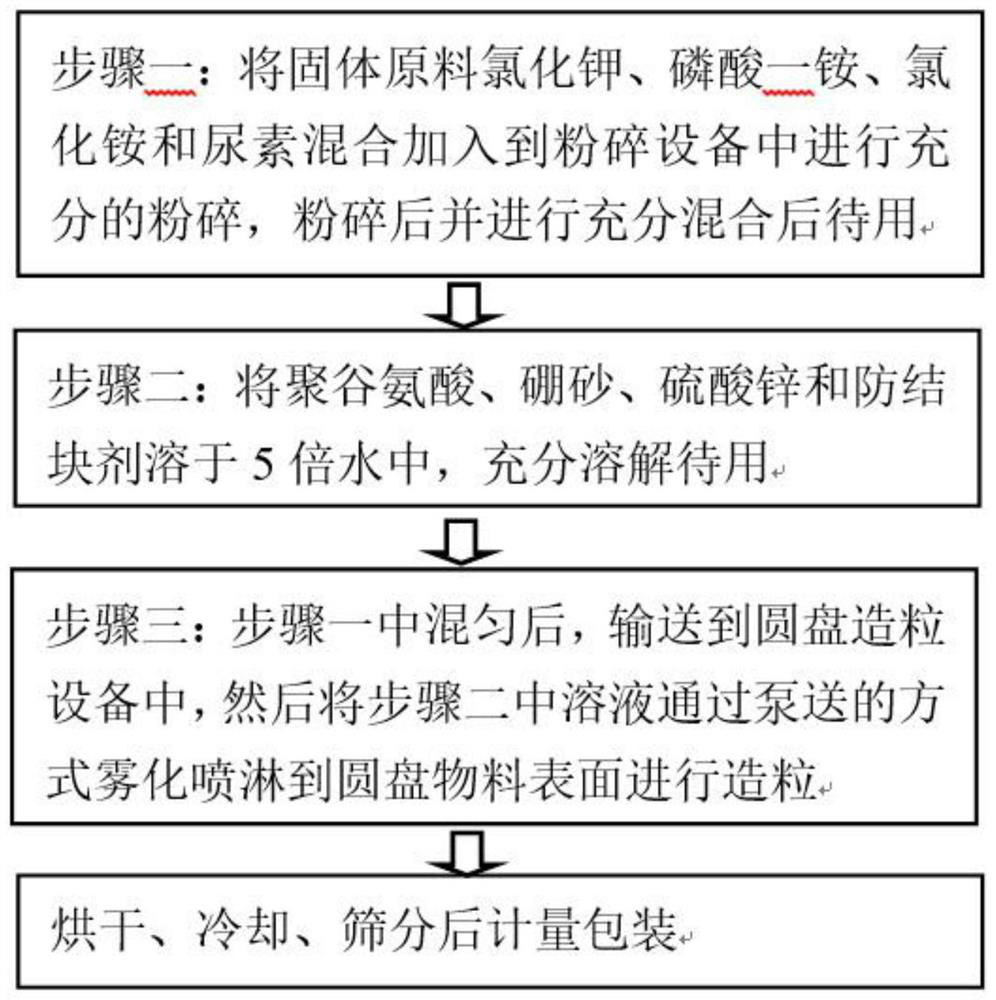

[0044] A preparation process of special compound fertilizer for wheat, comprising the following steps:

[0045] Step 1: the solid raw material potassium chloride, monoammonium phosphate, ammonium chloride and urea are mixed and added into the pulverizing equipment for sufficient pulverization, after pulverization and fully mixed, stand-by;

[0046] Step 2: Dissolve polyglutamic acid, borax, zinc sulfate and anti-caking agent in 5 times of water, fully dissolve and set aside;

[0047] Step 3: After mixing in step 1, transport it to the disc granulation equ...

Embodiment 2

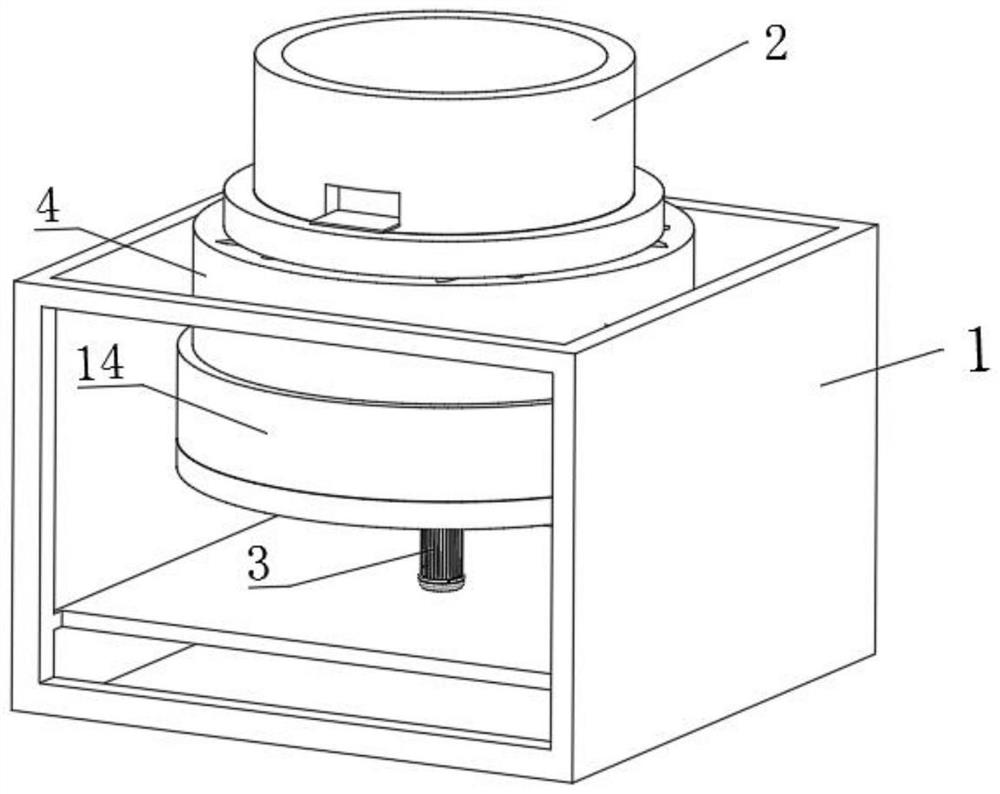

[0049] see Figure 2-10 , a special compound fertilizer for wheat, preparation process and granulation equipment thereof, comprising a support frame 1 and a rolling disc 2, the rolling disc 2 is rotatably installed inside the support frame 1, and a drive motor 3 is arranged inside the support frame 1 , the drive motor 3 is connected to the rolling disc 2;

[0050] A dry powder cylinder 4 is installed on the rolling disk 2, and a dry powder quantitative assembly 5 for promoting granulation and rolling is arranged inside the dry powder cylinder 4, and a first rotating plate 6 and a second rotating plate 6 and a second rotating plate are installed in the rolling disk 2 to rotate respectively. plate 7, several first holes 8 are provided on the first rotating plate 6 and the second rotating plate 7, and a return spring 12 is arranged between the first rotating plate 6 and the second rotating plate 7;

[0051] The dry powder quantitative component 5 includes a quantitative plate 9,...

Embodiment 3

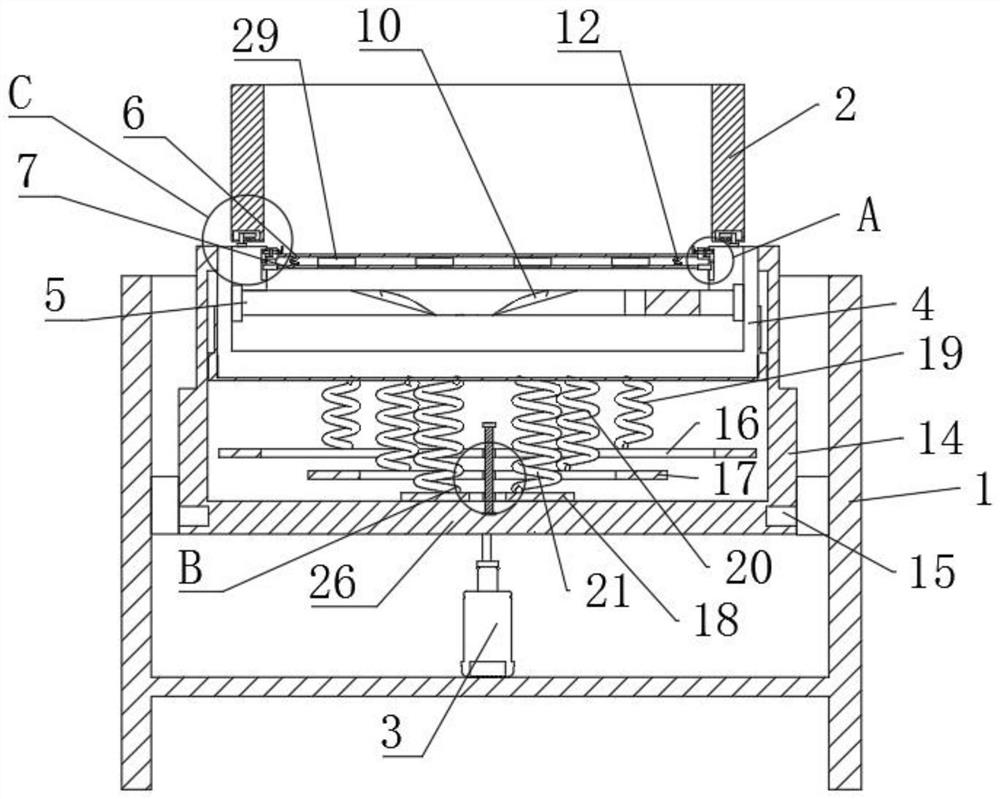

[0057] This embodiment is an improvement made to Embodiment 2, please refer to image 3 and Figure 5 , specifically, the dry powder cylinder 4 is provided with a reciprocating assembly for promoting the movement of the dry powder, and the reciprocating assembly includes a first movable plate 16, a second movable plate 17 and a third movable plate 18;

[0058] The inner bottom of the fixed seat 14 is rotatably equipped with a screw rod 36, and the screw rod 36 is screwed to the first movable plate 16, the second movable plate 17 and the third movable plate 18, and the first movable plate 16, the second movable plate The plate 17 and the third movable plate 18 are connected with the dry powder cylinder 4 .

[0059] The drive motor 3 is set as a forward and reverse geared motor;

[0060] The first movable plate 16, the second movable plate 17 and the third movable plate 18 in the reciprocating assembly are arranged in the fixed seat 14, and when the drive motor 3 rotates, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com