Preparation method and application of corn straw-based pseudocapacitor electrode material

A technology of corn stalks and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of difficulty in participating in the electrochemical charge storage process, poor cycle performance, and short diffusion distance, etc., and achieve improved electrochemical performance. performance, good electrical conductivity and mechanical ductility, the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

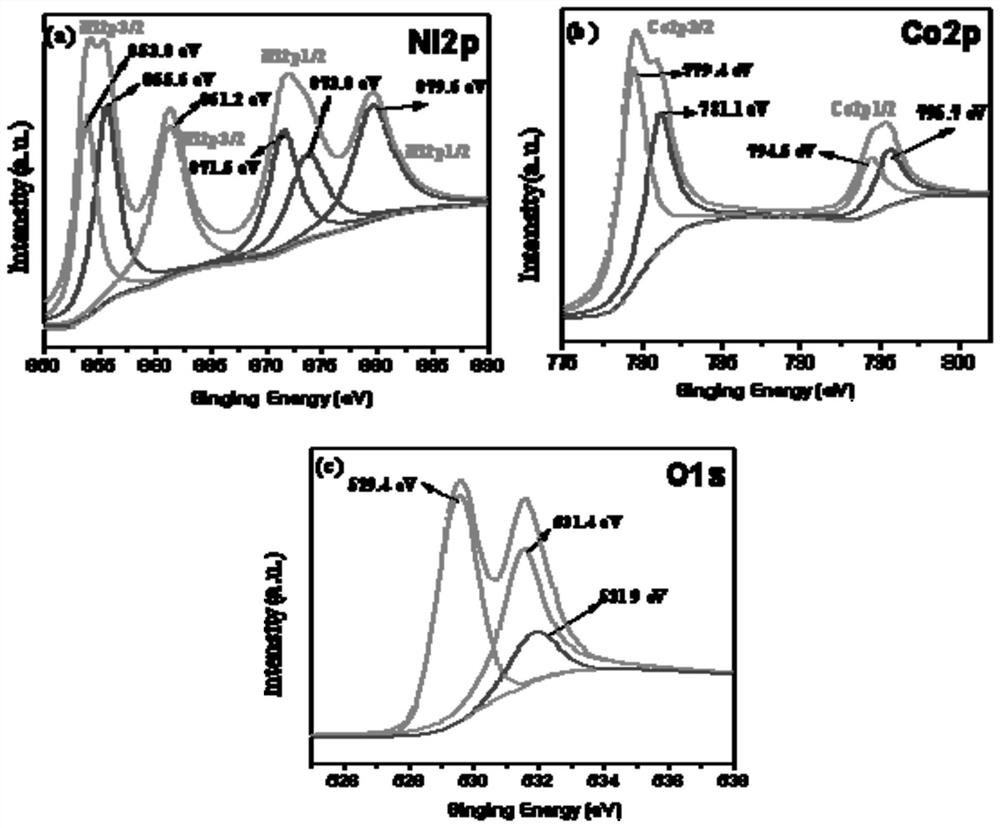

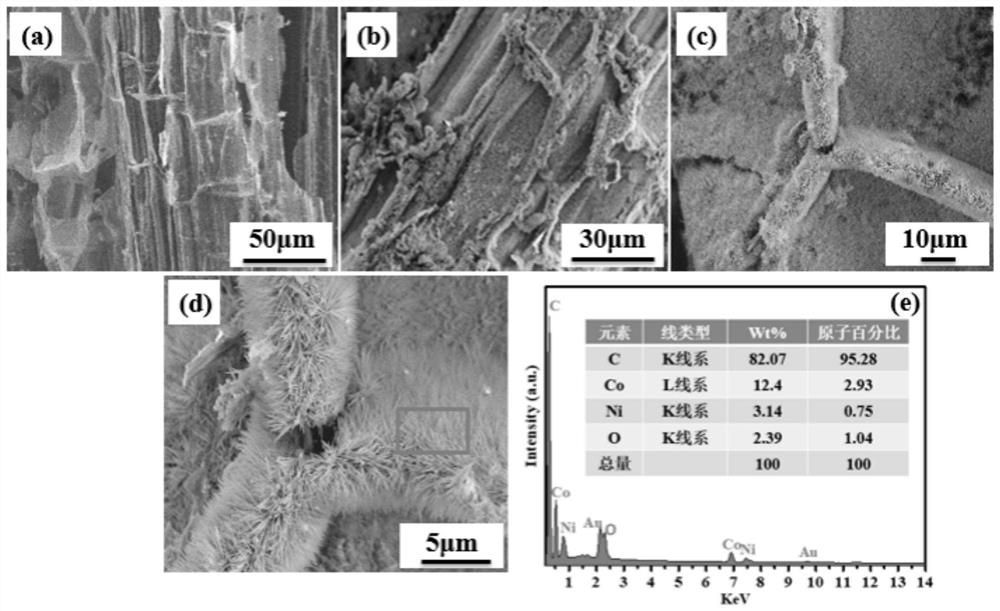

[0029] Embodiment 1: see attached Figure 1~3 Shown: a preparation method of a corn stalk-based pseudocapacitive electrode material, comprising the following steps:

[0030] (1) Pretreatment: Weigh 2g of corn stalks and put them into a 100ml hydrothermal reaction kettle, add 0.1mol / L citric acid to completely immerse the corn stalks in citric acid, heat and react at 200°C for 6 hours, Then wash with deionized water and dry to obtain the corn stalk hydrothermal carbon raw material;

[0031] (2) adding the corn stalk hydrothermal carbon raw material obtained in step (1) into a 4mol / L 40ml KO H solution, soaking for 12 hours, and drying at 60°C for 12 hours to obtain the corn stalk material before carbonization;

[0032] (3) Carbonization treatment: put the corn stalk material before carbonization obtained in step (2) into a tubular heating furnace, 2 Roasting under protection, the roasting process is divided into three stages: first set the heating rate at 5°C / min, first heat ...

example 1

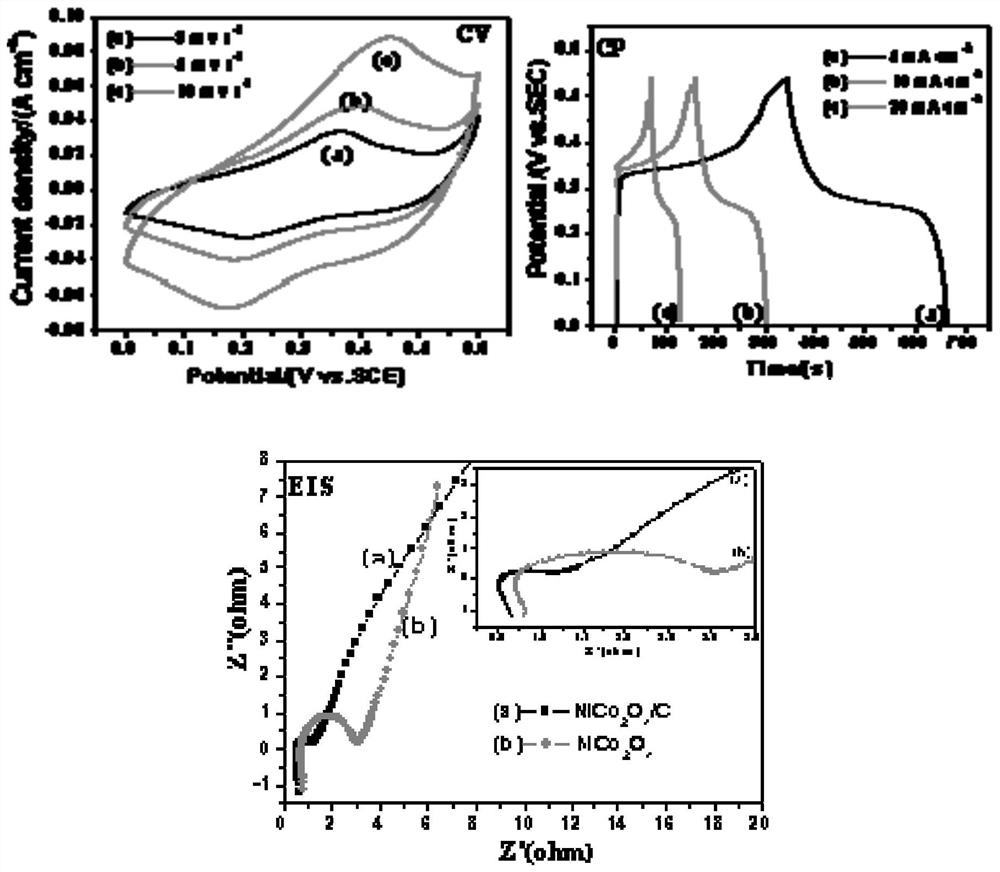

[0036] For example 1, according to the attached image 3 According to the CP characteristic curve of the specific capacitance, according to the calculation formula of specific capacitance C=IΔt / mΔV, when the current density is 5mA / cm2, the specific capacitance is 3181.82F / g. It shows that the special structure of corn stalk carbon makes the electrolyte ions in the solution can be inserted and extracted quickly, and has a high specific capacitance. According to attached image 3 The CEIS characteristic curve can further confirm that corn stalk carbon-based nickel cobaltate has a small internal resistance.

Embodiment 2

[0037] Embodiment 2: other experimental conditions are the same as embodiment 1, use NaOH or NaOH or Na in the electrolyte solution in step (2) 2 SO 4 , different electrochemical properties can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com