Soft and hard composite carbon as well as preparation method and application thereof

A soft-hard composite, soft carbon technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of hard carbon and soft carbon difficult to achieve uniform mixing, amorphous carbon core difficult to function, difficult to accurately adjust the migration channel and other problems , to achieve the effect of reliable bonding, alleviating the effect of volume expansion and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

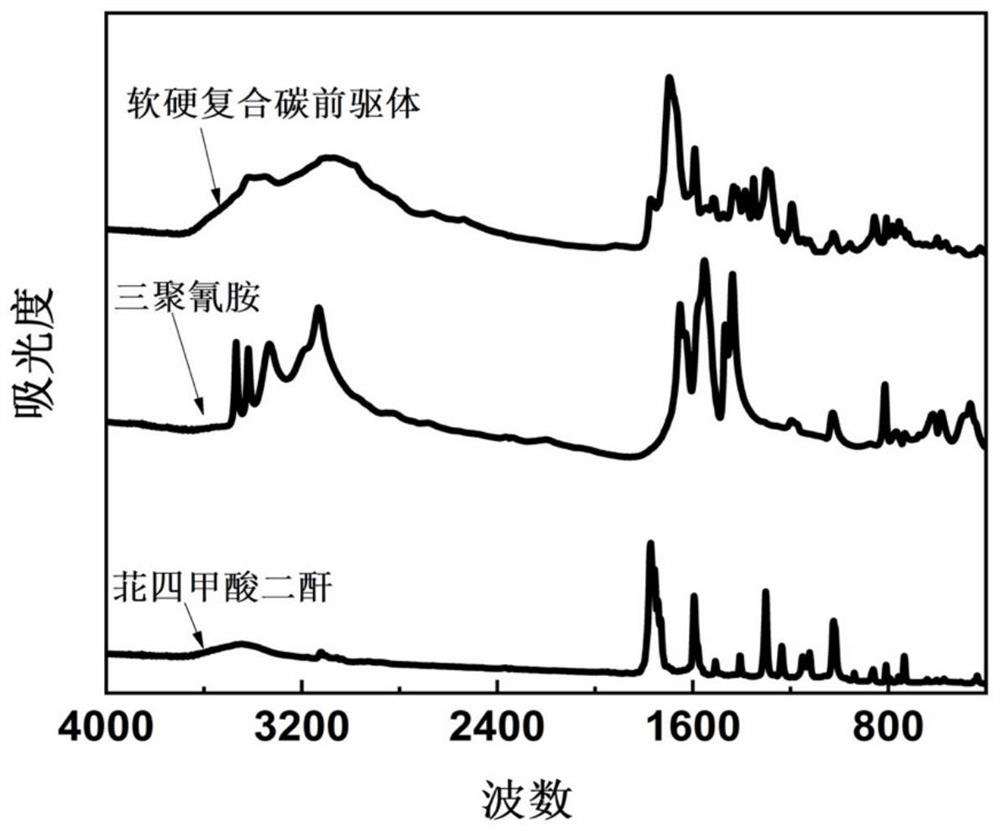

[0058] Add 0.02mol sodium hydroxide and 200.0mL deionized water into a beaker to form a solution, add 3mmoL perylenetetracarboxylic dianhydride, stir for 6h to obtain a mixed solution A of fluorescent green, add 6mmoL melamine to solution A, and stir for 3h , to obtain the precursor solution B, titrate the solution B with hydrochloric acid to be acidic under the stirring state, stir for 2 hours, obtain an orange suspension, filter it with suction and dry it at 60°C; transfer the dried product into a powder and transfer it to a tube furnace for argon Atmosphere, 3°C min -1 Heat up to 600°C for 2 hours; then 4°C for min -1 Heat up to 800°C for 2 hours; last 5°C for min -1 Raise the temperature to 1200°C for 3 hours to obtain a black soft-hard composite carbon-potassium battery material; use an intelligent Fourier transform infrared spectrometer to test and analyze the soft-hard composite carbon precursor, and the results are as follows figure 1 As shown, it shows that the prep...

Embodiment 2

[0062] Embodiment 2 (comparative example):

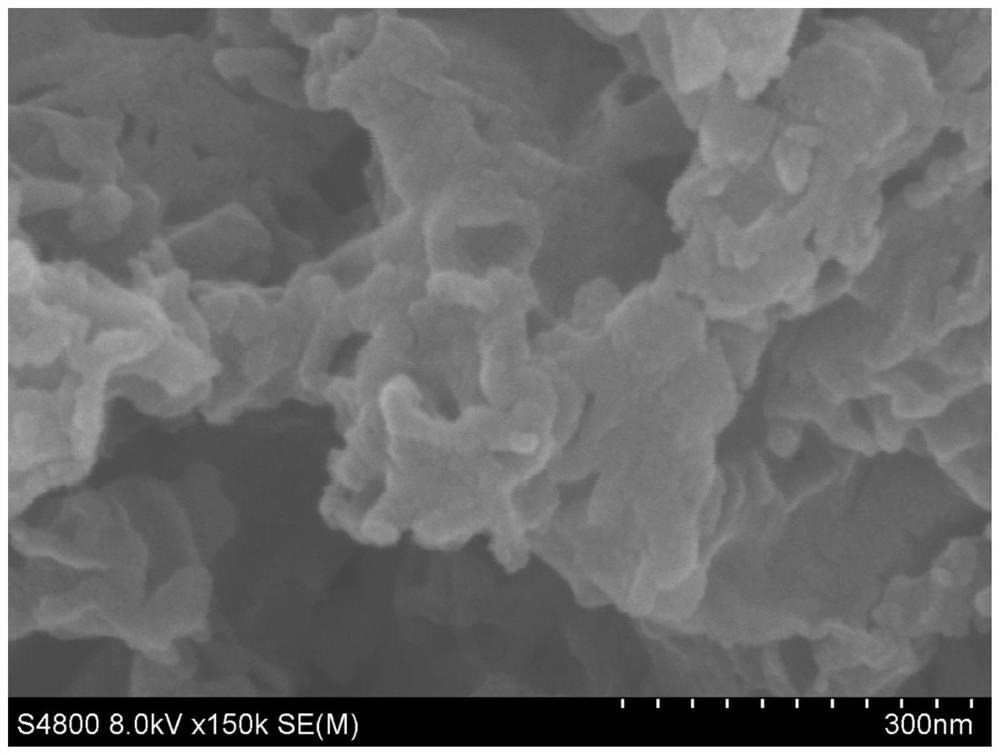

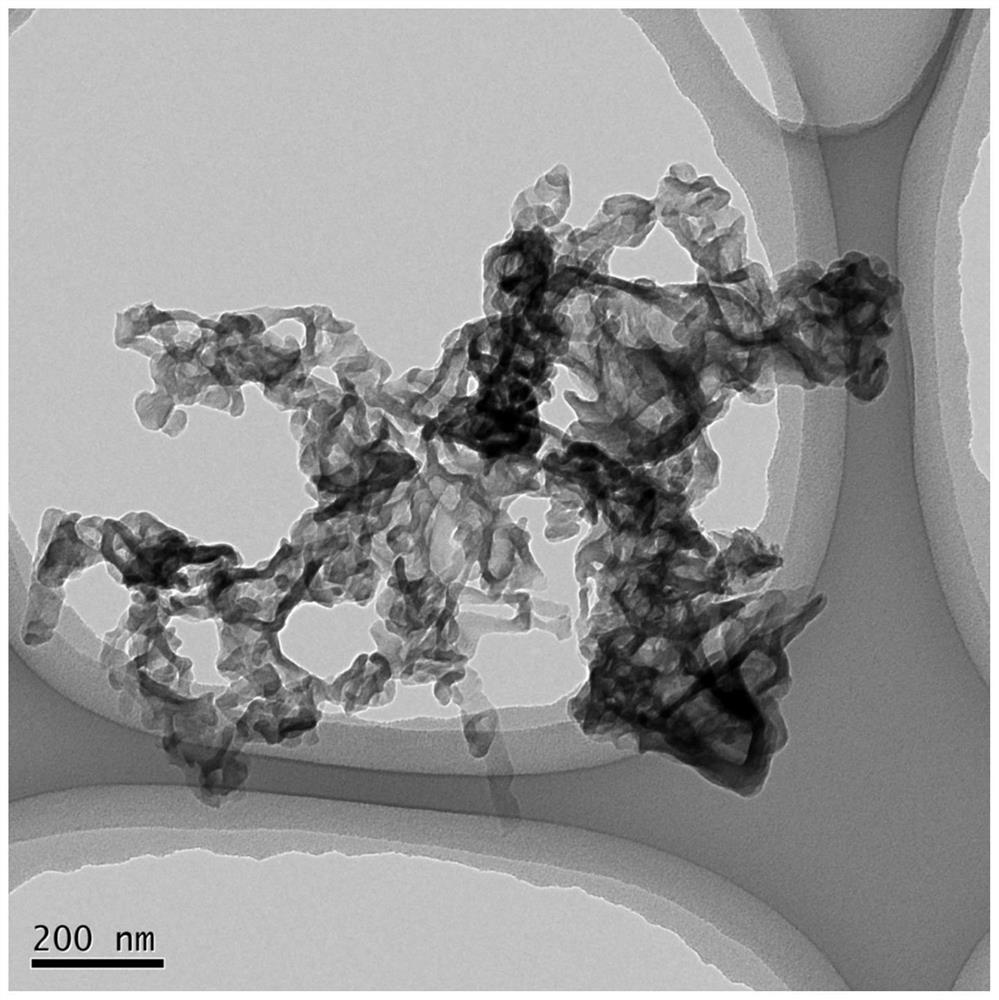

[0063] Add 0.02mol of sodium hydroxide and 200.0mL of deionized water into a beaker to form a solution, add 3mmol of perylenetetracarboxylic dianhydride, and stir for 6 hours to obtain a mixed solution A of fluorescent green. Under stirring, use hydrochloric acid to titrate solution A to make it acidic , stirred for 2 hours, suction filtered and dried at 60°C; the dried and ground powder product was transferred to a tube furnace under argon atmosphere, 3°C min -1 Heat up to 600°C for 2 hours; then 4°C for min -1 Heat up to 800°C for 2 hours; last 5°C for min -1 Raise the temperature to 1200°C for 3 hours to obtain a black soft carbon potassium battery material; analyze the composition and structure of the product by X-ray powder diffraction; analyze and test the morphology of the product by scanning electron microscopy, the results are as follows Figure 12 , as shown in 13, the characteristic peak of carbon can be found around 25...

Embodiment 3

[0065] Add 0.02mol sodium hydroxide and 200.0mL deionized water into a beaker to form a solution, add 3mmoL perylenetetracarboxylic dianhydride, stir for 6h, and obtain a mixed solution A of fluorescent green, add 4mmoL melamine into solution A, and stir for 3h , to obtain the precursor solution B, titrate the solution B with hydrochloric acid to be acidic under the stirring state, stir for 2 hours, obtain an orange suspension, filter it with suction and dry it at 60°C; transfer the dried product into a powder and transfer it to a tube furnace for argon Atmosphere, 3°C min -1 Heat up to 600°C for 2 hours; then 4°C for min -1 Heat up to 800°C for 2 hours; last 5°C for min -1 Raise the temperature to 1200°C for 3 hours to obtain a black soft-hard composite carbon-potassium battery material; analyze the composition and structure of the product by X-ray powder diffraction; analyze and test the morphology of the product with a scanning electron microscope, and the results obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com