Electrolyte and lithium ion battery

An electrolyte and lithium salt technology, applied in the field of electrolyte and lithium-ion batteries, can solve the problems of aggravating side reactions, the electrolyte is easily oxidized, and destroying the SEI on the surface of the negative electrode, so as to reduce side reactions, improve high-pressure cycle performance and storage. performance, the effect of suppressing battery gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

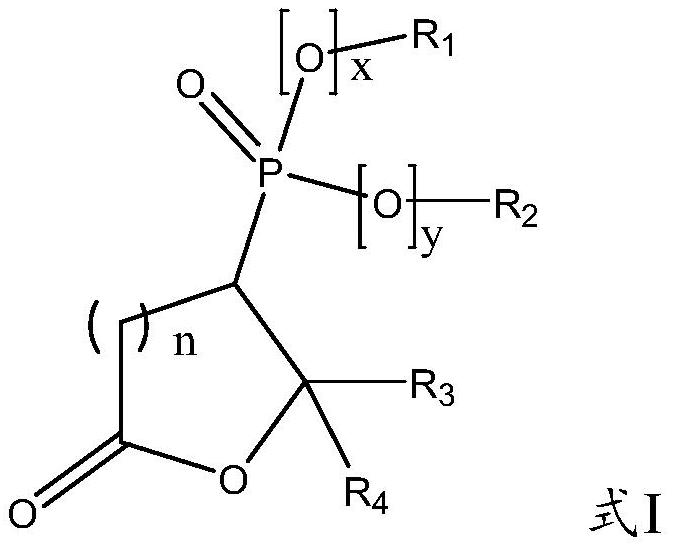

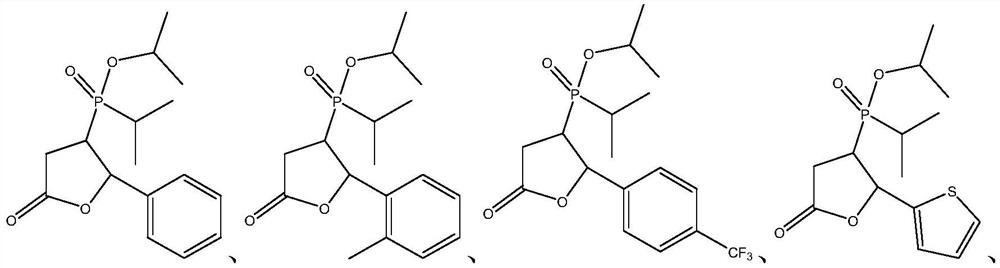

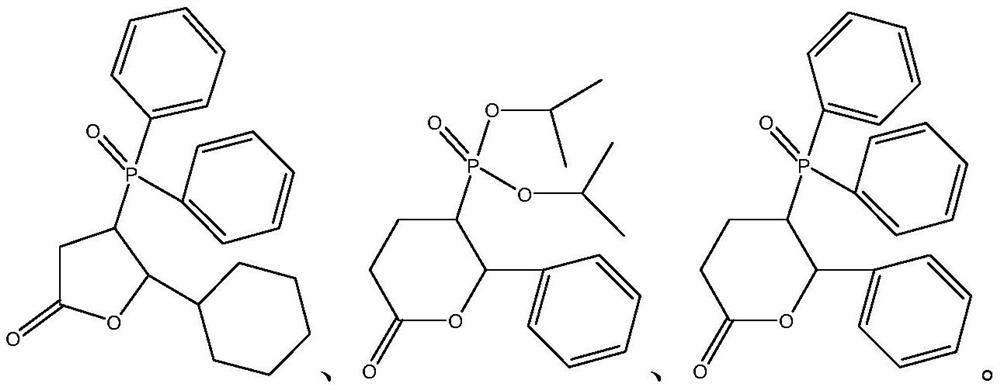

Method used

Image

Examples

Embodiment 1

[0075] (1) Preparation of positive electrode sheet for lithium ion battery

[0076] The cathode active material LiCoO 2 , conductive agent Super-P, CNT, and binder PVDF are mixed in a mass ratio of 95.5:2:1:1.5 and then dispersed in N-methylpyrrolidone (NMP), stirred and mixed evenly to obtain positive electrode slurry; the positive electrode slurry Evenly coated on the aluminum foil, after drying, go through the process of cold pressing and slitting to obtain the positive electrode sheet.

[0077] (2) Preparation of lithium-ion battery negative electrode sheet

[0078] Mix negative electrode active material SiO, negative electrode active material graphite, conductive agent Super-P, binder SBR and thickener CMC in a mass ratio of 15:80:2:1:2 and disperse them in deionized water, stir and mix evenly The negative electrode slurry is obtained; the negative electrode slurry is evenly coated on the copper foil, and after drying, the negative electrode sheet is obtained through co...

Embodiment 2

[0084] A lithium-ion battery was prepared according to the method of Example 1, except that in the preparation step of the electrolyte, the amount of fluoroethylene carbonate added accounted for 5% of the total mass of the electrolyte.

Embodiment 3

[0086] Lithium-ion batteries were prepared according to the method of Example 1, the difference being that in the preparation step of the electrolyte, the amount of compound 1 added accounted for 2% of the total mass of the electrolyte, and the amount of fluoroethylene carbonate added accounted for 2% of the total mass of the electrolyte. 5%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap