Preparation method of green high polymer material for humidity sensor

A technology of humidity sensor and polymer materials, which is applied in the field of preparation of green polymer materials, can solve problems such as uneven deposition of polymer solutions, environmental pollution of synthetic polymer materials, excessive material dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

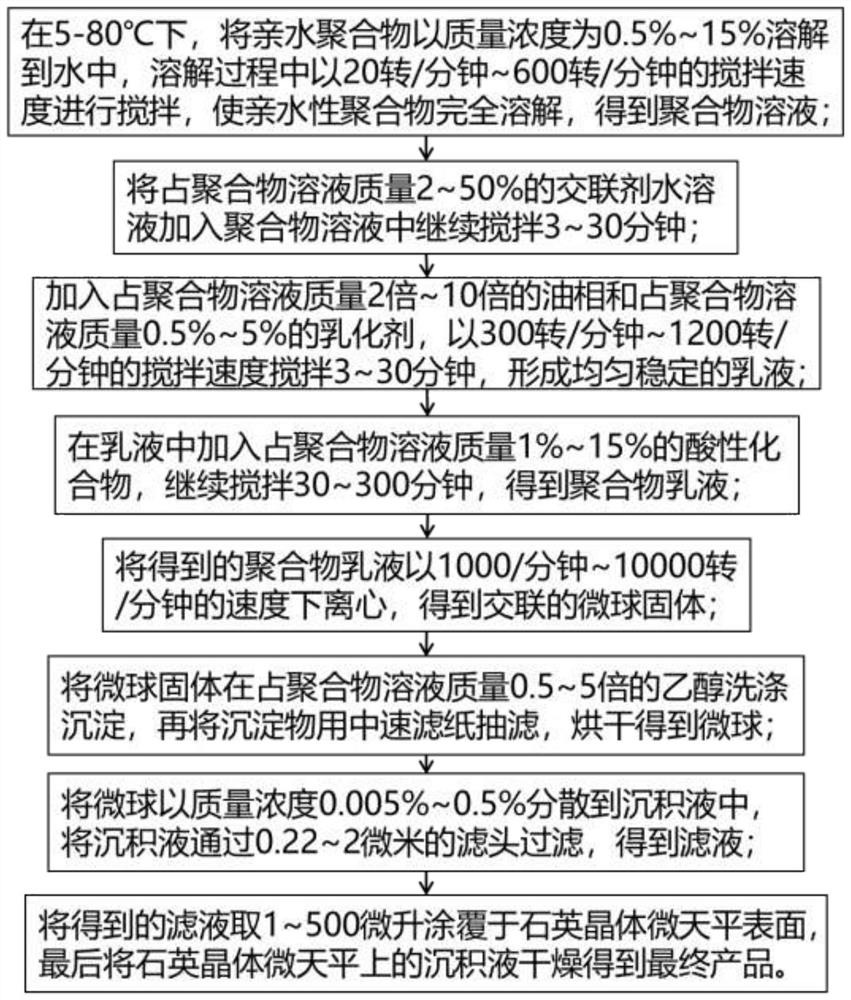

[0036] This embodiment describes the preparation of a high-sensitivity and fast-response humidity sensor based on a green polymer material with a sensitivity of 24.3 Hz / %RH and a response time of 30 seconds. Further, the good hysteresis characteristics of the humidity sensor prepared in this example are described. During specific implementation, the preparation method of the humidity sensor based on the green polymer material, such as figure 1 shown.

[0037] The preparation method of the humidity sensor based on the green polymer material comprises the following steps:

[0038] Step 1, preparing microspheres, specifically includes the following sub-steps:

[0039] Step 1.1, at a suitable temperature, stir and dissolve the hydrophilic polymer in a certain mass concentration range into water to obtain a polymer solution;

[0040] The range of the suitable temperature is 5-80°C, the range of a certain mass concentration is 0.5% to 15%; the stirring speed is 20 rpm to 600 rpm;...

Embodiment 2

[0074] This embodiment illustrates the preparation of a humidity sensor by using a method for preparing a green polymer material for a humidity sensor according to the present invention.

[0075] During specific implementation, the steps are as shown in steps 1 to 7 in the summary of the invention.

[0076] Wherein, the hydrophilic polymer described in step 1 is preferably sodium alginate, polyglutamic acid or hyaluronic acid; the mass concentration of the hydrophilic polymer dissolved in water is preferably 1-6%;

[0077] The cross-linking agent described in step 2 is preferably calcium carbonate, calcium sulfate, calcium chloride, calcium gluconate, calcium phosphate, iron carbonate, iron chloride, iron sulfate; The quality of cross-linking agent in the cross-linking agent aqueous solution The concentration is preferably 10% to 25%, and the crosslinking agent aqueous solution accounts for 5% to 20% of the mass of the polymer solution;

[0078] The oil phase described in ste...

Embodiment 3

[0085] This example illustrates the process of applying this method to prepare a polymer material and a humidity sensor with a sensitivity of 50 Hz / %RH and a response time of 35 seconds.

[0086] At 40°C, dissolve 0.4 grams of sodium alginate in 20 grams of water, stir at a speed of 200 rpm to completely dissolve the hydrophilic polymer; then dissolve 0.3 grams of calcium carbonate crosslinking agent in 3 grams of water, Add together in the compound solution and continue to stir for 15 minutes; Then add 100 grams of castor oil and 0.6 gram of Span 80, stir for 15 minutes with a stirring speed of 600 rev / min, form a uniform and stable emulsion; add 1 gram of glacial acetic acid again, Continue to stir for 60 minutes; centrifuge the polymer emulsion at a speed of 3000 / min to obtain cross-linked microsphere solids; then wash and precipitate the microsphere solids in 100 grams of ethanol solution; then pump the precipitates with medium-speed filter paper Filter and dry to obtain m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com