Concentration and separation method of alpha-lactalbumin

A technology of lactalbumin and separation method, which is applied in the concentration and separation of α-lactalbumin, the production of concentrated and isolated whey protein and the preparation of α-lactalbumin, which can solve the waste of resources, difficulty in separation by membrane separation, and difficulty in separation, etc. problems, achieve the effect of reducing adsorption strength, low production cost and effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: After passing the milk through the curd, the whey water is collected by filtration, and the lactose is concentrated by the 5K ultrafiltration membrane to increase the whey protein content;

[0041] Step 2: Adjust the pH of the concentrated whey protein solution (a1) to 11.22 with 0.25mol / L food-grade sodium hydroxide, and then adjust the pH to 4.86 with 0.5mol / L food-grade hydrochloric acid, and the protein in the solution will flocculate .

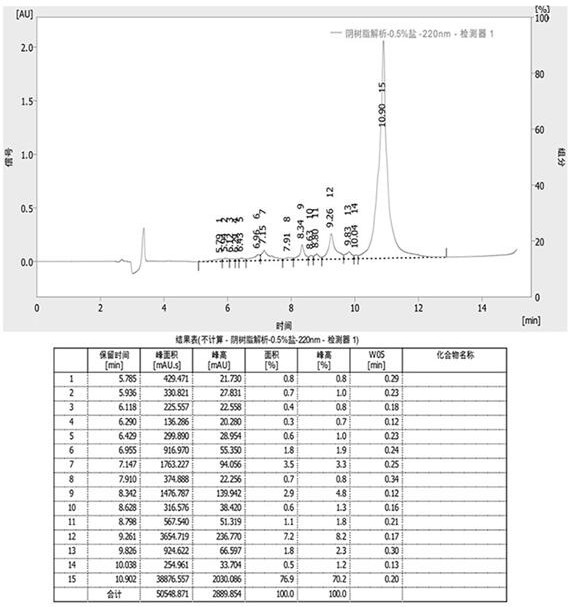

[0042] Step 3: Separate the solution through a 0.8 μm ceramic membrane, adjust the pH of the dialysis water to 4.76, and wash out the non-flocculated protein as much as possible by continuously adding dialysis water. The concentrated solution (b1) obtained is mainly concentrated β-lactoglobulin solution; the clear solution (c1) obtained is mainly a mixed solution of α-lactalbumin and immunoglobulin G.

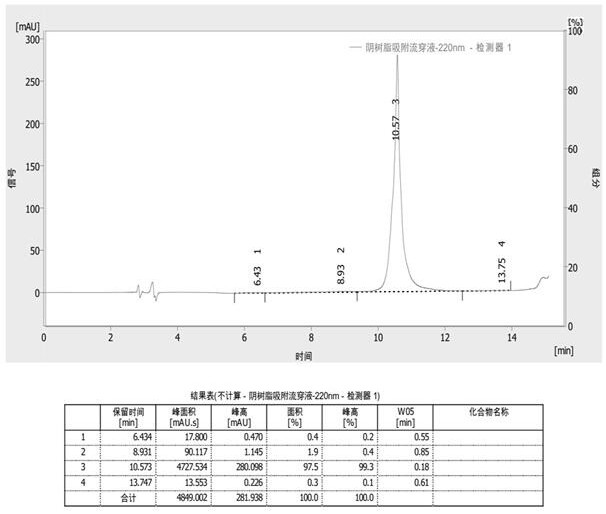

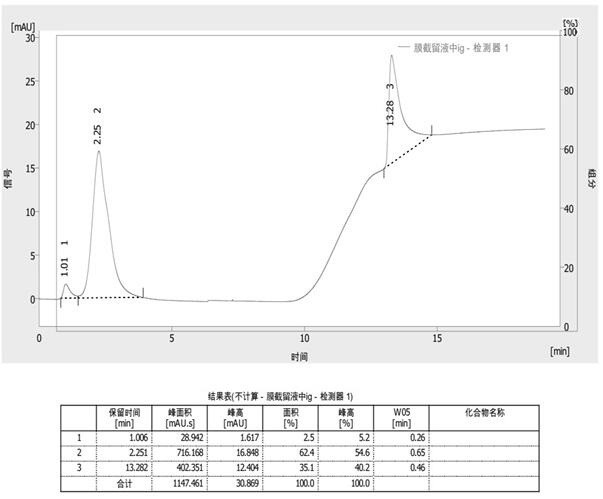

[0043] Step 4: The supernatant (c1) passes through a 100K ultrafiltration membrane to mainly retain macromolecular protei...

Embodiment 2

[0050] Step 1: Dissolve WPC80 whey protein powder (a2) at a concentration of 4%, adjust the pH to 11.17 with 0.25mol / L food-grade sodium hydroxide, then adjust the pH to 4.92 with 0.25mol / L food-grade acetic acid, The protein in the solution flocculates.

[0051] Step 2: Separate the solution through a 0.8 μm ceramic membrane, adjust the pH of the dialysis water to 5.16, and wash out the non-flocculated protein as much as possible by continuously adding dialysis water. The concentrated solution (b2) obtained is mainly concentrated β-lactoglobulin solution; the clear solution (c2) obtained is mainly a mixed solution of α-lactalbumin and immunoglobulin G.

[0052] Step 3: The supernatant (c2) passes through a 100K ultrafiltration membrane to mainly retain macromolecular proteins such as immunoglobulin G in the solution. The concentrated liquid (d2) obtained is mainly concentrated immunoglobulin G solution; the clear liquid (e2) obtained is mainly concentrated α-lactalbumin solu...

Embodiment 3

[0059] Step 1: Dissolve WPI90 isolated whey protein powder (a3) at a concentration of 5%, adjust the pH to 11.22 with 0.25mol / L food-grade sodium hydroxide, then adjust the pH to 11.22 with 0.2mol / L food-grade citric acid 4.86, the protein in the solution flocculates.

[0060] Step 2: Separate the flocculation solution through a centrifuge at a speed of 2000r / min and a centrifugation time of 10min. After the centrifugation is completed, the precipitate (b3) obtained is mainly concentrated β-lactoglobulin product; the supernatant (c3) obtained is mainly α-lactalbumin and immunoglobulin G mixed solution.

[0061] Step 3: The supernatant (c3) passes through a 50K ultrafiltration membrane to mainly retain macromolecular proteins such as immunoglobulin G in the solution. The concentrated liquid (d3) obtained is mainly concentrated immunoglobulin G solution; the clear liquid (e3) obtained is mainly concentrated α-lactalbumin solution.

[0062] Step 4: After adjusting the clear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com