Universal biodegradable plastic antibacterial master batch as well as preparation method and application thereof

A technology for degrading plastics and antibacterial masterbatches, applied in the field of plastic modification processing, can solve the problems that antibacterial additives cannot be uniformly dispersed, the degradable compatibility is limited, and the antibacterial properties of products are affected, so as to shorten the processing and molding cycle and improve antibacterial properties Efficacy, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

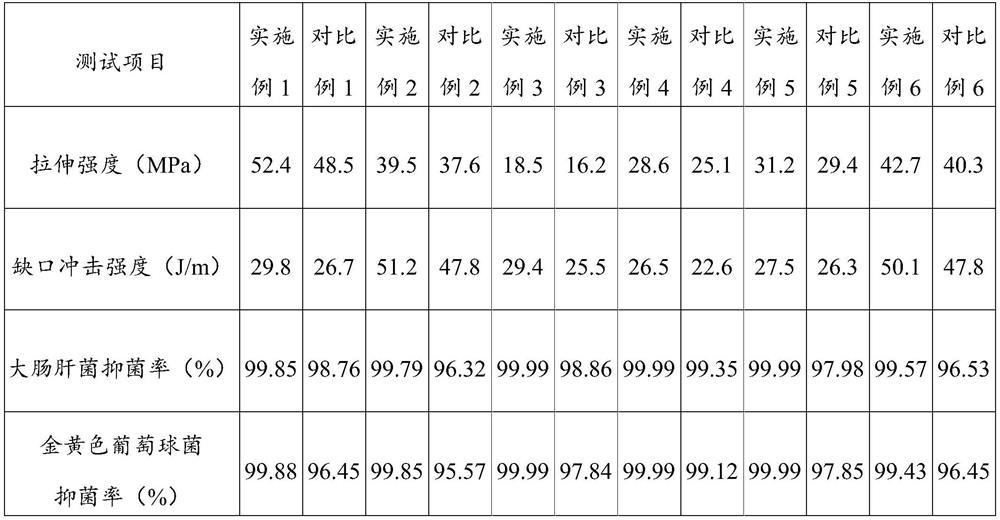

Examples

Embodiment 1

[0036] The present embodiment provides a general-purpose biodegradable plastic antibacterial masterbatch, the mass ratio of its components is as follows: 30.0kg PLA; 30.0kg PBS; 20.0kg PHB; 0.1kg tetrabutyl titanate; 15.0kg glass / Silver zinc ion antibacterial agent (Bactekiller BM-102TG) of zeolite carrier; 2.0kg nano cerium oxide; 1.0kg mesoporous zirconium hydrogen phosphate; 0.9kg pentaerythritol stearate; 1.0kg calcium stearate.

[0037] The present embodiment also provides the preparation method of above-mentioned antibacterial masterbatch, specifically comprises the following steps:

[0038] S1, premixing: weigh PLA, PBS, PHB, tetrabutyl titanate, silver zinc ion antibacterial agent of glass / zeolite carrier, nano cerium dioxide, mesoporous zirconium hydrogen phosphate, pentaerythritol stearate and Calcium stearate, and it is dropped into high-speed mixer successively and premixed, obtains premix;

[0039] S2. Thermal mixing: Transfer the premixed material obtained in s...

Embodiment 2

[0042]This embodiment provides a general-purpose biodegradable plastic antibacterial masterbatch, the mass ratio of its components is as follows: 25.0kg PLA; 30.0kg PBS; 25.0kg PHB; 0.07kg tetrabutyl titanate; 14.0kg glass carrier 3.0kg nanometer cerium oxide; 2.0kg mesoporous zirconium hydrogen phosphate; 0.5kg ethylene-vinyl acetate copolymer wax; 0.43kg zinc stearate.

[0043] The present embodiment also provides the preparation method of above-mentioned antibacterial masterbatch, specifically comprises the following steps:

[0044] S1. Premixing: Weigh PLA, PBS, PHB, tetrabutyl titanate, silver ion antibacterial agent on glass carrier, nano-cerium dioxide, mesoporous zirconium hydrogen phosphate, ethylene-vinyl acetate copolymer wax and Zinc stearate, and it is put into high-speed mixer successively and carries out premixing, obtains premix;

[0045] S2. Thermal mixing: Transfer the premix obtained in step S1 to an internal mixer for thermal mixing. The mixing temperature...

Embodiment 3

[0048] The present embodiment provides a general-purpose biodegradable plastic antibacterial masterbatch, the mass ratio of its components is as follows: 25.0kg PLA; 30.0kg PBS; 25.0kg PHB; 0.05kg tetrabutyl titanate; 18.0kg glass / Zeolite carrier silver zinc ion antibacterial agent (Bactekiller BM-102SD); 1.0kg nanometer cerium oxide; 2.5kg mesoporous zirconium hydrogen phosphate; 0.55kg ethylene-acrylic acid copolymer wax; 0.9kg oleic acid amide.

[0049] The present embodiment also provides the preparation method of above-mentioned antibacterial masterbatch, specifically comprises the following steps:

[0050] S1. Premixing: Weigh PLA, PBS, PHB, tetrabutyl titanate, silver zinc ion antibacterial agent on glass / zeolite carrier, nano-cerium dioxide, mesoporous zirconium hydrogen phosphate, ethylene-acrylic acid copolymer wax according to the above mass and oleic acid amide, and put it into a high-speed mixer successively for premixing to obtain a premix;

[0051] S2. Thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com