Composite pipeline for hydrogen conveying and hydrogen leakage monitoring method

A composite pipeline and hydrogen technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of hydrogen diffusion loss, rapid detection and repair, and different detection accuracy, so as to reduce hydrogen transmission loss and prevent Escape at will and improve the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation process of the composite pipeline for hydrogen transportation of the present invention is divided into three steps:

[0053] First, prepare the inner plastic pipe: set the heating temperature of each section of the main barrel and head of the plastic extruder. The overall temperature is within 175~225°C, and the heating temperature adjustment range of each section is ±10°C. After reaching the set temperature, Constant temperature for 90-150 minutes; when the heating temperature of the barrel and each section of the machine head reaches the set temperature (±2°C) and there is no significant change within the constant temperature period, start the machine, first start the main engine screw to run at a low speed (5-10r / min), and then Start the feeder screw to feed at low speed (5-10r / min); add the start-up material first, and then add the conventional production material (PE100) to extrude the pipe after the extrusion is normal; after the extrusion pipe trac...

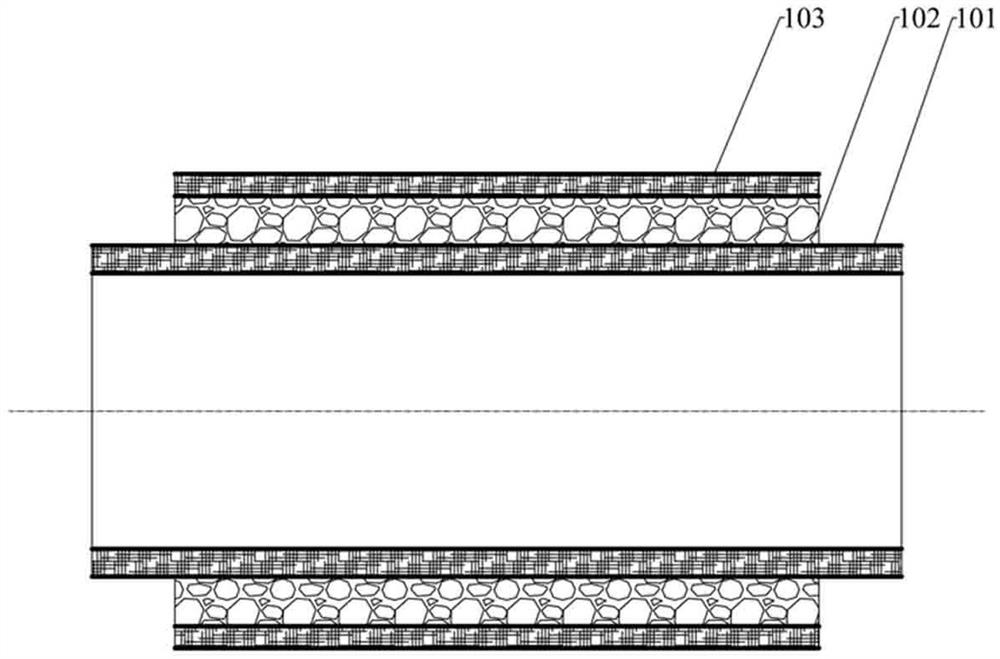

specific Embodiment 1

[0057] The composite pipeline of the present invention adopted in the pipeline of a certain hydrogen transportation pipeline has an overall structure such as Figure 4shown. Specific parameters of the pipe: the nominal diameter of the inner plastic pipe is 600mm, the outer diameter is 630mm, and the wall thickness is 10mm; the thickness of the polyurethane foam layer in the middle layer is 15mm; the inner diameter of the outer plastic protective layer is 660mm, and the thickness is 10mm. According to the specific parameters, use the factory assembly line to produce composite pipes: First, the production process of the inner plastic pipe: set the heating temperature of each section of the plastic extruder host barrel and head, the overall temperature is within 220 °C, and the heating temperature adjustment range of each section is ±10°C, after reaching the set temperature, keep the temperature constant for 120 minutes; when the heating temperature of the barrel and each section...

specific Embodiment 2

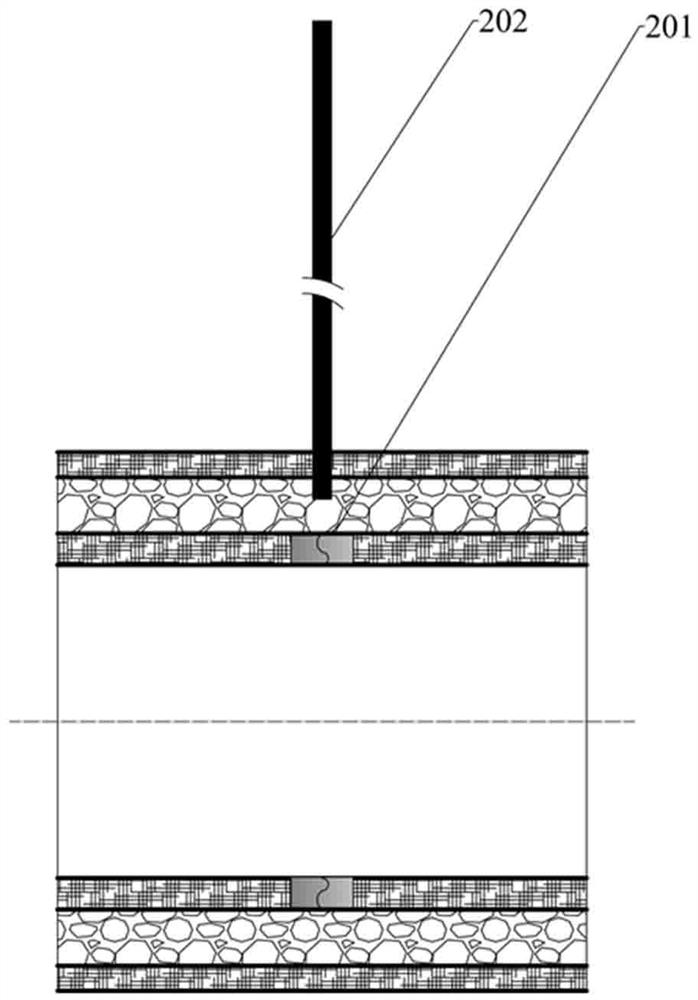

[0060] The structure of a long-distance hydrogen transport pipeline is as follows: Figure 4 As shown, the specific structural dimensions of the pipe are as follows: the nominal diameter of the inner plastic pipe is 300mm, the outer diameter is 325mm, and the wall thickness is 8mm; the thickness of the polyurethane foam layer in the middle layer is 10mm; the inner diameter of the outer plastic protective layer is 345mm , the thickness is 5mm. The specific conditions for the hydrogen transportation of the pipeline are: the pressure is 1.8MPa, and the flow rate is about 2160m3 / h. During the operation of the pipeline, worker B2 heard the alarm sound, and observed the hydrogen concentration curve of the signal receiver and processor at the corresponding time, and found that the equipment detected a jump in the hydrogen concentration. Worker B2 immediately checks the hydrogen concentration curve of the whole pipeline at the corresponding time, such as Figure 9 Shown; After obser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com