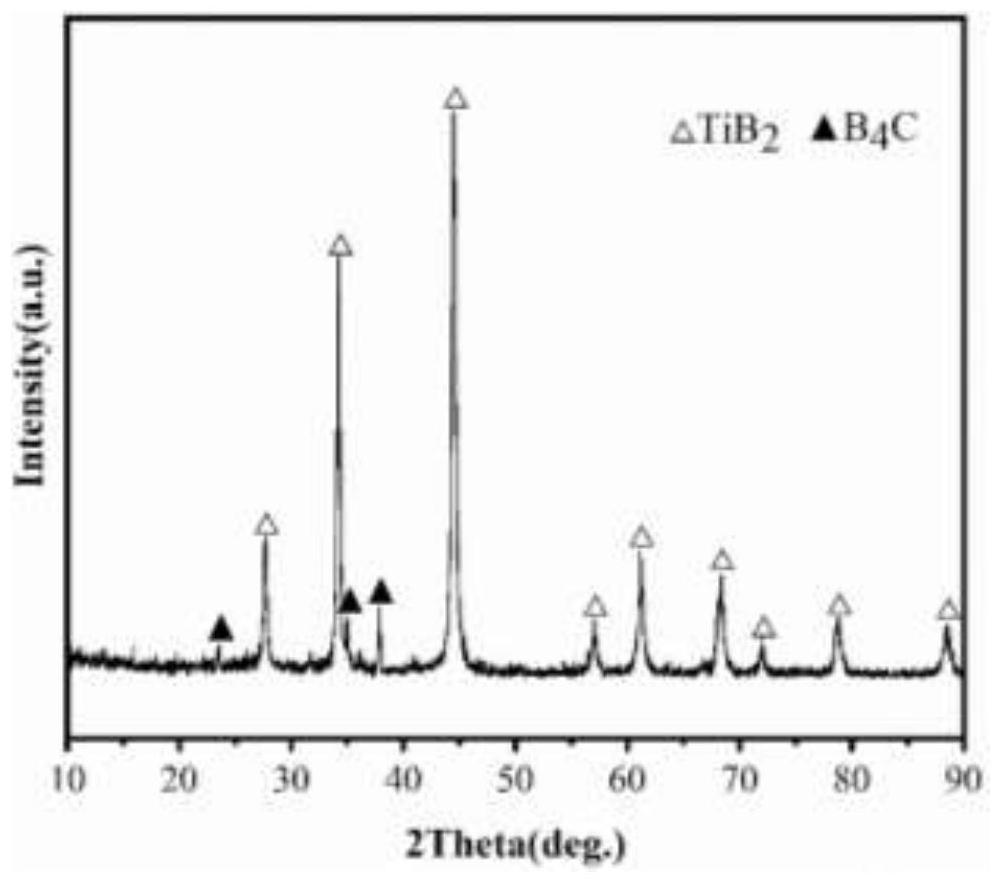

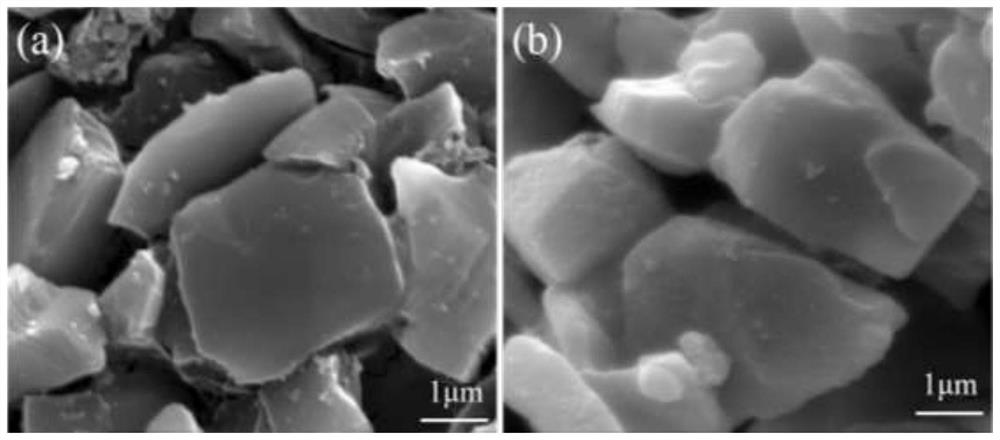

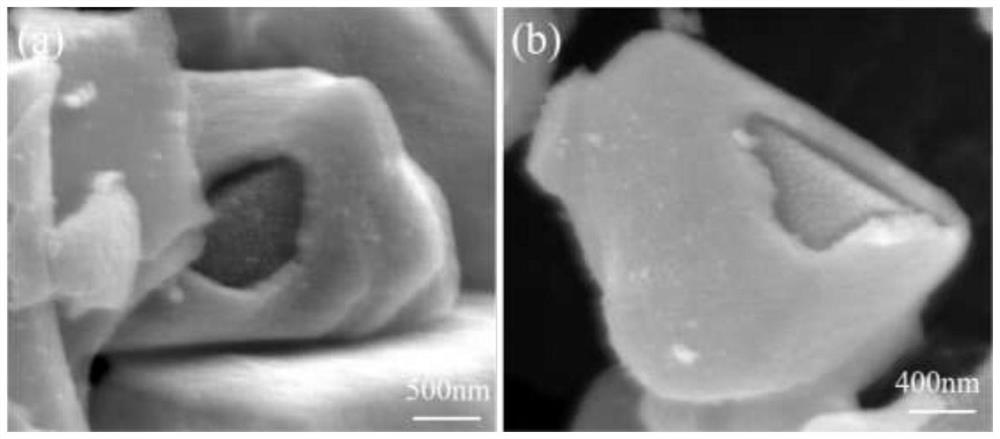

Molten salt preparation method of B4C-coated TiB2 composite powder with core-shell structure

A core-shell structure and composite powder technology, which is applied in the field of molten salt preparation of B4C@TiB2 composite powder, can solve the problems of high sintering temperature, low fracture toughness and low bending strength of single-phase boron carbide, and achieves low cost, The effect of good electrical conductivity and excellent sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A B with a core-shell structure 4 C@TiB 2 The molten salt preparation method of composite powder comprises the following steps:

[0044] 1) Add 10g of boron carbide into a mixed acid containing 10mL of hydrofluoric acid (concentration: 40wt%) and 10mL of nitric acid (concentration: 65wt%), soak for 12h; then wash with deionized water for 3 times and absolute ethanol for 3 times, after filtration, dry in an 80°C blast drying oven;

[0045] 2) Weigh 7g of acid-corroded boron carbide and 3g of titanium powder, and mix them uniformly to obtain mixed reaction raw materials;

[0046] 3) take by weighing 25g sodium chloride and 25g potassium chloride, mix uniformly to obtain alkali metal base molten salt raw material;

[0047] 4) Mix the alkali metal salt-based molten salt raw material and the mixed reaction raw material evenly, then put it into a graphite crucible, place it in a box-type atmosphere furnace protected by an argon atmosphere, and heat the box-type atmosphere ...

Embodiment 2

[0051] A B with a core-shell structure 4 C@TiB 2 The molten salt preparation method of the composite powder is roughly the same as that of Example 1, except that the temperature of the box-type atmosphere furnace is raised to 800° C. and then kept for 6 hours.

Embodiment 3

[0053] A B with a core-shell structure 4 C@TiB 2 The molten salt preparation method of composite powder comprises the following steps:

[0054] 1) Add 10g of boron carbide into a mixed acid containing 10mL of hydrofluoric acid (mass concentration: 40%) and 10mL of nitric acid (mass concentration: 65%), soak for 12h; then wash with deionized water for 3 times and absolute ethanol 3 times, after filtering, dry in an 80°C blast drying oven;

[0055] 2) Weigh 6g of acid-etched boron carbide and 4g of titanium powder, and mix them uniformly to obtain mixed reaction raw materials;

[0056] 3) take by weighing 50g sodium sulfate and 50g potassium sulfate, mix uniformly to obtain alkali metal base molten salt raw material;

[0057] 4) Mix the alkali metal salt-based molten salt raw material and the mixed reaction raw material evenly, then put it into a graphite crucible, place it in a box-type atmosphere furnace protected by an argon atmosphere, and heat the box-type atmosphere fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com