Application of PAG quenching liquid in quenching and tempering process of wind power main shaft of more than 20t

A wind power spindle and quenching liquid technology, applied in the direction of quenching agent, manufacturing tools, furnaces, etc., can solve the problems of high quenching cost, poor labor environment, unfavorable environmental protection, etc., and achieve low comprehensive cost, long effective life, and oxidative degradation. Effects of low aging rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The performance and concentration of the selected PAG quenching liquid are shown in Table 1.

[0018] name concentration temperature(℃ / s) V / max(°C / s) V / 300(°C / s) PAG 5%-9% 30 ≥190 ≤80

[0019] Table I

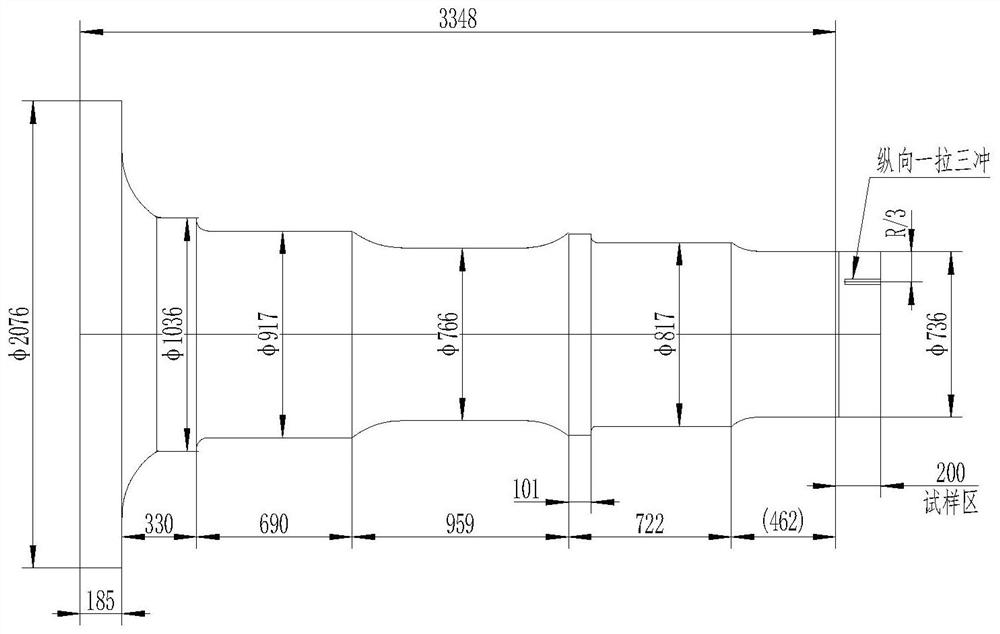

[0020] The material of the spindle selected for debugging is: 34CrNiMo6, the quenched and tempered weight: 20.1t, its mechanical properties are shown in Table 2 below, the quenched and tempered size and sampling are as follows figure 2 shown.

[0021]

[0022] Table II

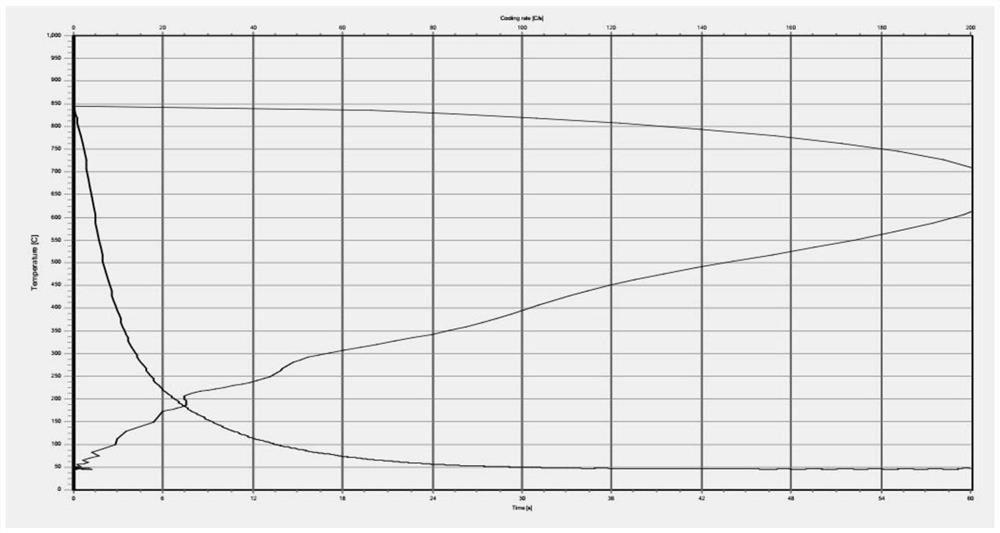

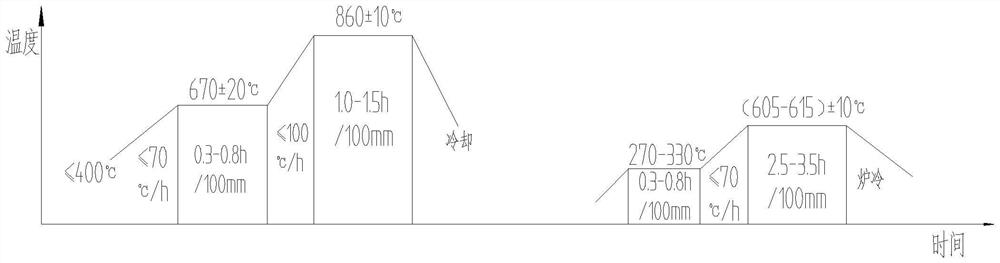

[0023] The debugging process of this application is: quenching heating and heat preservation stage, quenching cooling stage, tempering stage, wherein the operation of quenching heating and heat preservation stage, tempering stage is as follows image 3 shown.

[0024] In the quenching and cooling stage, PAG quenching liquid is used for single-liquid quenching. When quenching, the control points are as follows:

[0025] 1. It takes less than 4 minutes for the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com