Concentrated solution manufacturing device and method based on CO2 phase change equilibrium regulation and control

A manufacturing method and concentrated liquid technology, applied in the field of concentrated liquid manufacturing based on CO2 phase change equilibrium regulation, and concentrated liquid manufacturing device based on CO2 phase change equilibrium regulation, which can solve the problems of sublethal microorganisms, limited bactericidal effect, and high concentration energy consumption. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

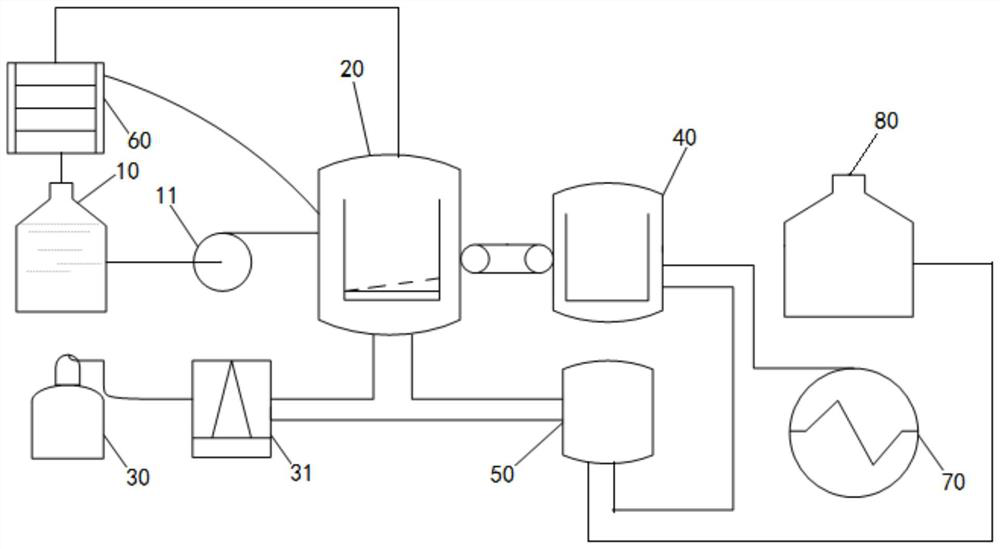

[0081] A kind of lychee concentrated juice preparation method, it adopts CO-based 2 A method for producing a concentrated liquid controlled by phase transition equilibrium, which specifically includes the following steps:

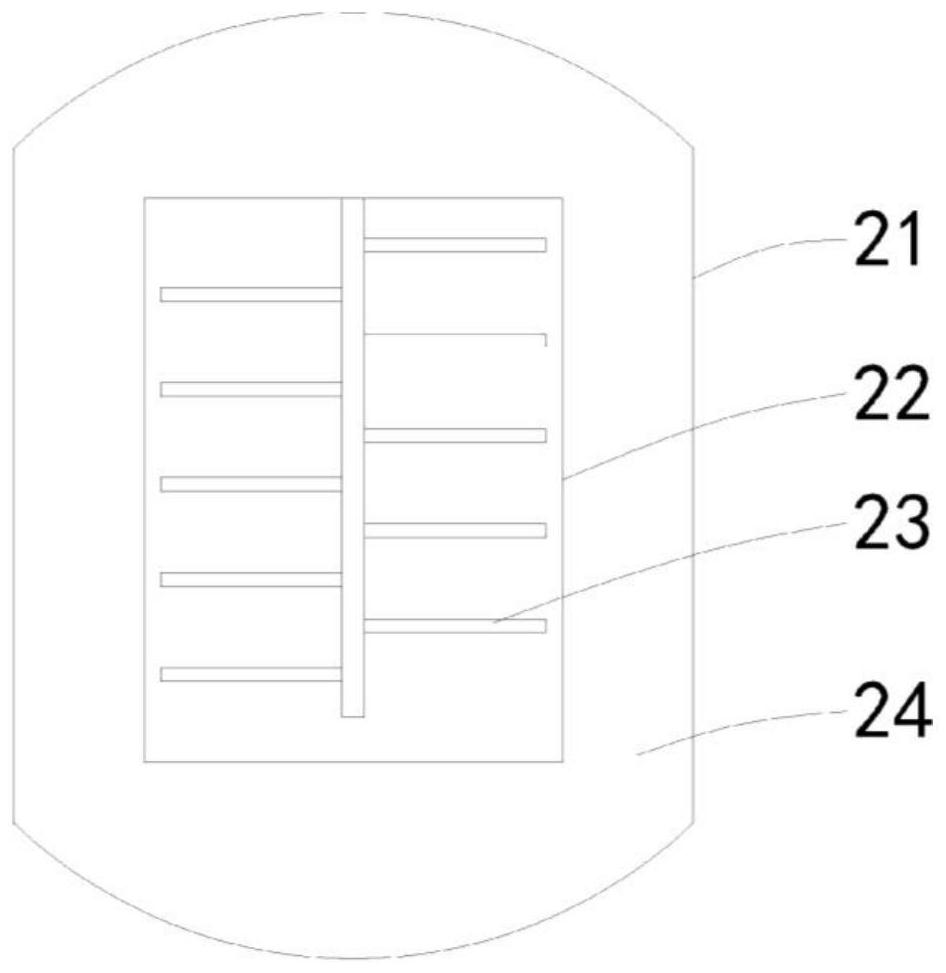

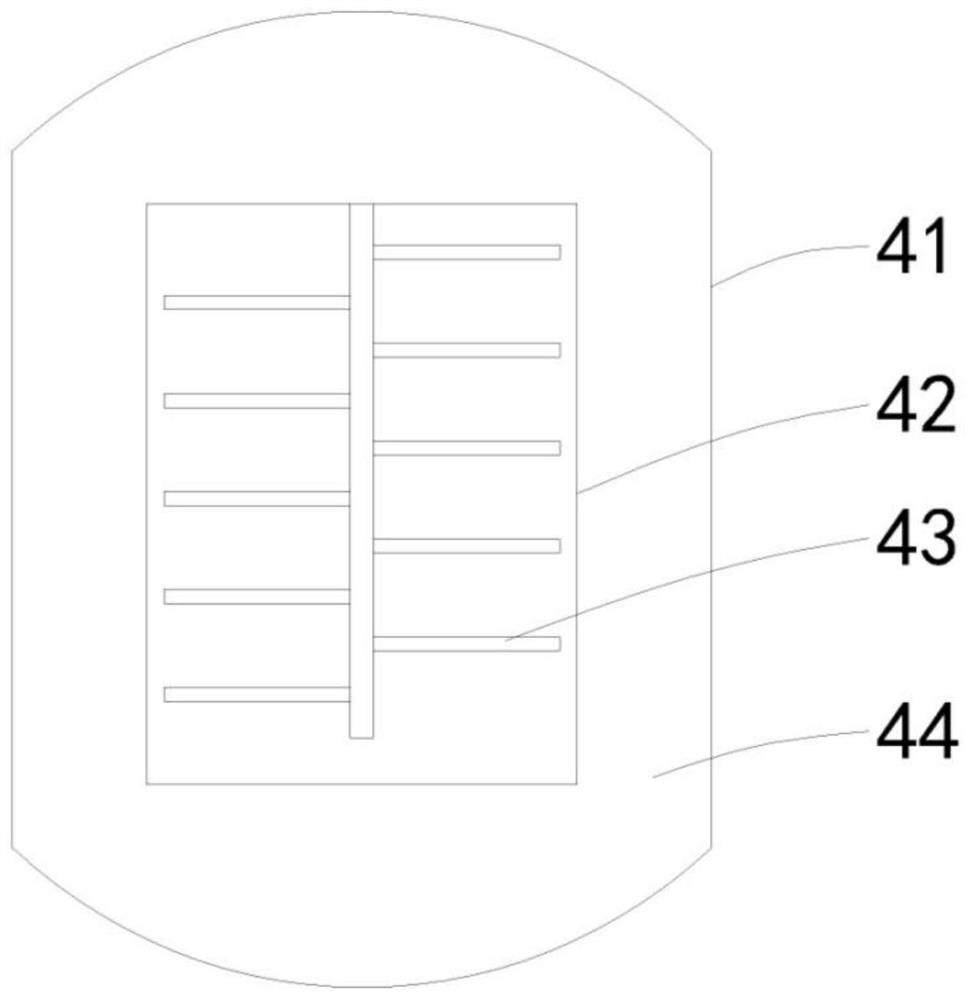

[0082] Extract and obtain litchi vitamin C extract with a solid content of 4 ° brix, and pre-cool to 15 ° C. Turn on the condensing circulation system 60 for cooling, so that the temperature of the feed tank 10 and the concentration processor 20 is consistent with the precooling temperature of the liquid material. Get the pre-cooled 2.5L extract and pump it into the inner cavity of the concentration processor 20 from the feed tank 10; open the CO 2 Dewar bottle 30, adjust the bubble diameter to 10 2 nm, after the pressure reaches 50bar, turn on the stirring device 23 of the concentration processor 20 at the same time, set the rotation speed to 500rpm / min, and process for 10min; adjust the condensation cycle, reduce the temperature of the concentration pro...

Embodiment 2

[0084] A kind of lychee concentrated juice preparation method, it adopts CO-based 2 A method for producing a concentrated liquid controlled by phase transition equilibrium, which specifically includes the following steps:

[0085] Litchi raw juice (gui flavor), solid content 10°brix, pre-cooled to 15°C. Turn on the condensing circulation system 60 for cooling, so that the temperature of the feed tank 10 and the concentration processor 20 is consistent with the precooling temperature of the liquid material. Get pre-cooled cinnamon fruit juice 2.5L and pump it into the inner cavity of the concentrated processor 20 from the feed tank 10; open the CO 2 Dewar bottle 30, adjust the bubble diameter to 10 3 nm, after the pressure reaches 90bar, turn on the stirring device 23 of the concentration processor 20 at the same time, set the rotation speed to 500rpm / min, and process for 10min; adjust the condensation cycle, reduce the temperature of the concentration processor 20 to 6°C, an...

Embodiment 3

[0087] A kind of lychee concentrated juice preparation method, it adopts CO-based 2 A method for producing a concentrated liquid controlled by phase transition equilibrium, which specifically includes the following steps:

[0088] Litchi juice (gui flavor), solid content 15°brix, pre-cooled to 15°C. Turn on the condensing circulation system 60 for cooling, so that the temperature of the feed tank 10 and the concentration processor 20 is consistent with the precooling temperature of the liquid material. Get pre-cooled cinnamon fruit juice 2.5L and pump it into the inner cavity of the concentrated processor 20 from the feed tank 10; open the CO 2 Dewar bottle 30, adjust the bubble diameter to 10 5 nm, after the pressure reaches 120bar, turn on the stirring device 23 of the concentration processor 20 at the same time, set the rotation speed to 1200rpm / min, and process for 10min; adjust the condensation cycle, reduce the temperature of the concentration processor 20 to 4°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com