Heat-insulating anti-fog glass and preparation method thereof

A technology of anti-fog glass and glass substrate, which is applied in glass manufacturing equipment, glass furnace equipment, glass molding, etc., and can solve problems such as troublesome pretreatment procedures, difficulty in uniform spreading, and indoor lighting discounts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

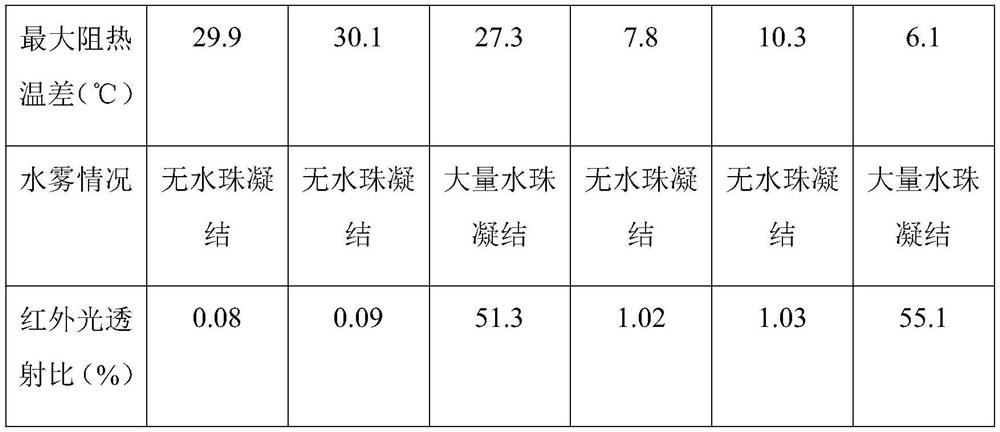

Embodiment 1

[0030] A heat-insulating and anti-fog glass, mainly comprising: 70 parts of modified silicon dioxide, 1 part of calcium fluoride, 4 parts of aluminum oxide, 9 parts of sodium oxide, 4 parts of magnesium oxide, and 10 parts by weight. Diboron trioxide, 5 parts potassium carbonate, 26 parts titanium dioxide.

[0031] A method for preparing heat-insulating and anti-fog glass, which mainly includes the following preparation steps:

[0032] (1) Put the silicon dioxide in a ball mill for 20 minutes, the mass ratio of the ball to material is 40:1, and the speed is 250r / min; put it on the rotating disk of the magnetron sputtering equipment, the speed is 30rpm, rotate forward for one week and then reverse One week, alternately, under 1Pa working pressure and high-purity argon atmosphere, using metal zirconium target, sputtering distance is 40cm, depositing zirconium / silicon dioxide for 10min, among which, the distance between the target and the magnetron sputtering equipment is 20 Pla...

Embodiment 2

[0038] A heat-insulating and anti-fog glass, mainly comprising: 85 parts of modified silicon dioxide, 3 parts of calcium fluoride, 9 parts of aluminum oxide, 15 parts of sodium oxide, 8 parts of magnesium oxide, and 15 parts by weight. Diboron trioxide, 10 parts potassium carbonate, 48 parts titanium dioxide.

[0039] A method for preparing heat-insulating and anti-fog glass, the method for preparing the heat-insulating and anti-fog glass mainly includes the following preparation steps:

[0040] (1) Put the silicon dioxide in a ball mill for 30 minutes, the mass ratio of the ball to material is 40:1, and the speed is 250r / min; put it on the rotating disk of the magnetron sputtering equipment, the speed is 30rpm, rotate forward for one week and then reverse One week, alternately, under 3Pa working pressure and high-purity argon atmosphere, using metal zirconium target material, sputtering distance is 50cm, depositing zirconium / silicon dioxide for 15min, among which, the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com