Transition layer material, application and process for improving internal stress of charge of warhead

A transitional layer and warhead technology, applied in the direction of explosives, ammunition, non-explosive/non-thermal agent components, etc., can solve the problems of ammunition launch safety hazards, chamber explosion, etc., to eliminate charge defects, easy compression deformation, Effect of reducing or charging defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the transition layer material is as follows: add butadiene rubber and ethylene-vinyl acetate copolymer into a beaker, add an appropriate amount of petroleum ether solvent, heat and stir to dissolve, add aluminum powder after completely dissolving, stir and mix evenly from Pour it out from the beaker, and after the solvent volatilization material is muddy or viscous, pass through an 8-12 mesh sieve or a granulator to prepare granular materials for later use.

[0036] combined with figure 1 As shown, the present invention uses the transition layer material to improve the internal stress process of the special-shaped warhead charge, including:

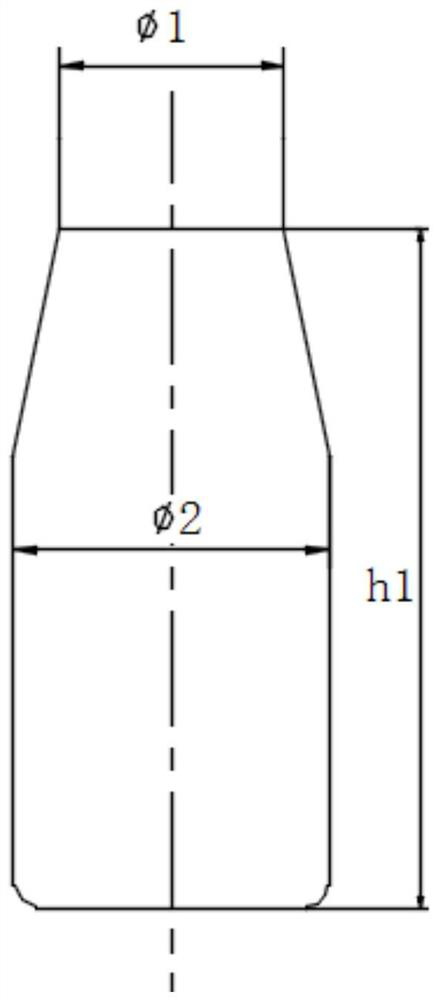

[0037] Choose a special-shaped warhead simulation bomb with a mouth diameter φ1 of 40-80mm, a bottom diameter φ2 of 80-120mm, and a height of 150-300mm, and fight against the mouth of the warhead simulation bullet with a special-shaped structure. The pressure sensor is assembled on the bottom of the simul...

Embodiment 1

[0040] This embodiment discloses a transition layer material, including the following raw material components: in terms of mass percentage, 20% of composite modified material, 80% of metal powder; the composite modified material is made of butadiene rubber and ethylene-vinyl acetate copolymer The substance is composed of a mass ratio of 3:1.

[0041] The transition layer material disclosed in this embodiment is used to improve the internal stress of the special-shaped warhead charge.

[0042] Further, the process of using the transition layer material to improve the internal stress of the special-shaped warhead charge includes:

[0043] combined with figure 1 As shown, the selected mouth diameter φ1 is 40mm, the bottom diameter φ2 is 80mm, and the height is 150mm of special-shaped structure warhead simulation projectile, and the body mouth of the special-shaped structure warhead simulation projectile and the special-shaped structure warhead simulation projectile A pressure s...

Embodiment 2

[0053] In the present embodiment, select mouth diameter φ1 to be 80mm, bottom diameter φ2 is 120mm, and height is 300mm special-shaped warhead simulation projectile, and the projectile body mouth and special-shaped structure warhead of described special-shaped structure warhead simulation projectile A pressure sensor is assembled at the bottom of the simulated bomb; then 200g of the transition layer material is placed at the bottom of the warhead simulated bomb with a special-shaped structure, and the RL-F explosive charge is carried out by a step-by-step pressing process. The pressing process parameters: pressure 150Mpa, divided into five times Compression, the amount of explosives for each compression in the first three times is 1200g, and 700g in the last two times, and the final average charge density is controlled to 1.7g / cm 3 . In an embodiment, the total charge is 5000g.

[0054] The transition layer material selected in this embodiment includes the following raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com