High-gloss acrylic latex as well as preparation method and application thereof

A technology of acrylic latex and acrylic acid, which is applied in the field of polymer materials, can solve problems such as insufficient gloss and adhesion, achieve the effects of improving gloss and adhesion, solving insufficient gloss and adhesion, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

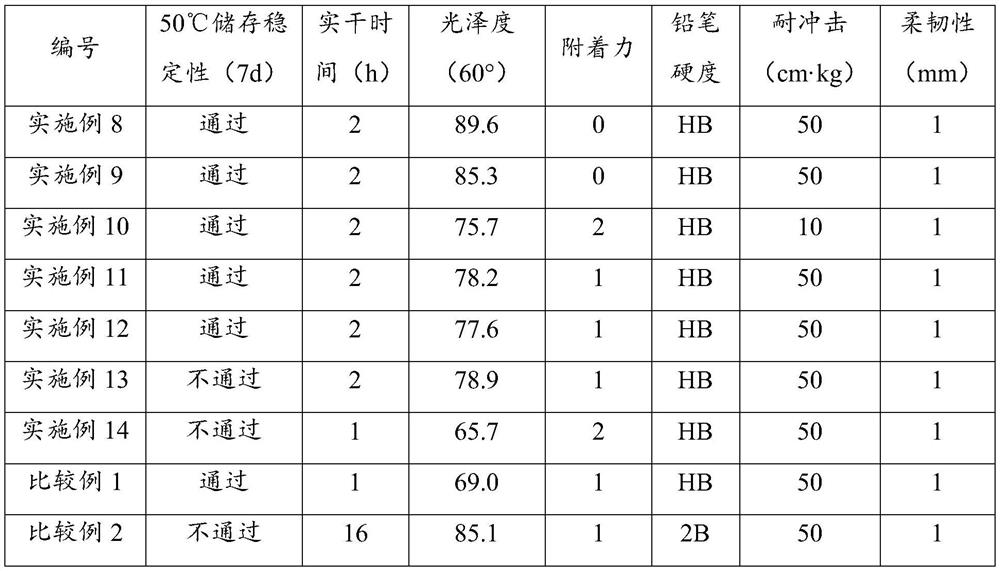

Examples

preparation example Construction

[0067] In a specific embodiment of the present invention, the preparation method of the water-dispersed alkyd-acrylic acid hybrid secondary dispersion includes: taking the alkyd resin intermediate and fatty acid into the reaction bottle, and then raising the temperature to 130-150°C, Then drop the mixture of the monomer mixture, the initiator and the chain transfer reagent, and the dropping time is 2 to 3 hours. After the dropping, the initiator is added, and the heat preservation is continued for 2 to 3 hours; after the heat preservation is completed, add fatty acid, Esterification catalyst and antioxidant, heat up to 180±5°C for esterification and dehydration reaction until the acid value is between 30 and 60 mgKOH / g, vacuum out the solvent and cool down, add co-solvent when the temperature drops to 140±5°C, continue Cool down to 80±5°C, add neutralizer for neutralization for 0.5-1 hour, then add water to invert and dilute.

[0068] In a specific embodiment of the present in...

Embodiment 1

[0089] The present embodiment provides the preparation method of high light type acrylic latex, comprises the steps:

[0090] (1) Preparation of water-dispersible alkyd-acrylic acid hybrid secondary dispersion

[0091] (a) Preparation of alkyd resin intermediate: 109.3 parts of soybean oil fatty acid, 172.9 parts of trimethylolpropane, 143.2 parts of phthalic anhydride, 0.4 part of triphenylphosphine, 0.8 part of hypophosphorous acid (50wt% aqueous solution) and 12 parts of xylene Put it into a reaction tank, raise the temperature to 220-230° C. for esterification and dehydration until the acid value is lower than 5 mgKOH / g, cool down and add 45 parts of xylene to discharge.

[0092] (b) Preparation of water-dispersed alkyd-acrylic acid hybrid secondary dispersion: Take 110 parts of alkyd resin intermediate and 48 parts of soybean oil fatty acid prepared in step (a) and add them to the reaction bottle, then heat up to 130-150 ℃, then dropwise added 47.35 parts of methyl metha...

Embodiment 2

[0098] The present embodiment provides the preparation method of high light type acrylic latex, comprises the steps:

[0099] (1) Preparation of water-dispersible alkyd-acrylic acid hybrid secondary dispersion

[0100] (a) Preparation of alkyd resin intermediate: 200 parts of soybean oil fatty acid, 54 parts of neopentyl glycol, 62.24 parts of pentaerythritol, 66.12 parts of phthalic anhydride, 49.48 parts of isophthalic acid, 16 parts of benzoic acid, 0.4 part of triphenylphosphine , 0.8 parts of hypophosphorous acid (50wt% aqueous solution) and 12 parts of xylene are put into the reaction tank, the temperature is raised to 220~230 ℃ for esterification and dehydration until the acid value is lower than 10mgKOH / g, the xylene is extracted, and the temperature is discharged.

[0101] (b) Preparation of water-dispersed alkyd-acrylic acid hybrid secondary dispersion: 142.35 parts of alkyd resin intermediate and 50.35 parts of dipropylene glycol butyl ether prepared in step (a) wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com