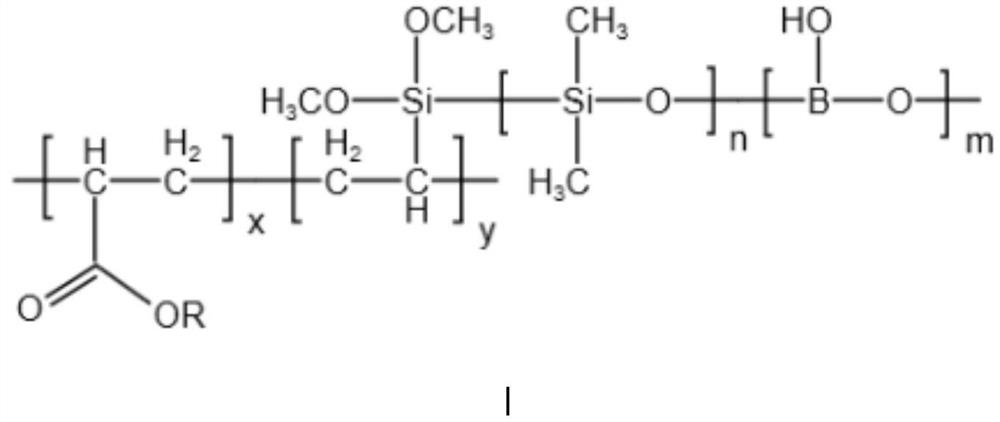

Polyborosiloxane modified polyacrylate foaming material as well as preparation method and application thereof

A technology of polyborosiloxane and polyacrylate, which is applied in the field of polyborosiloxane modified polyacrylate foam material and its preparation, can solve the problem that the protective performance of polyacrylate foam does not meet the application of OLED industry. , to achieve high energy absorption rate, good stability, and the effect of improving energy absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

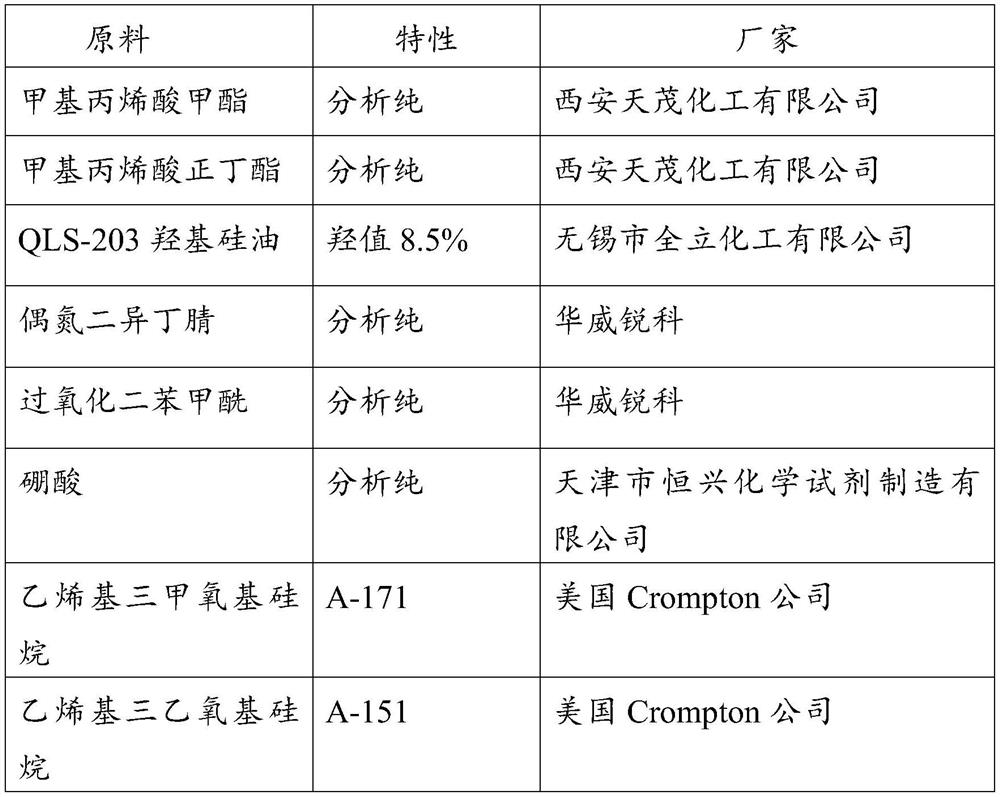

[0036] The polyborosiloxane-modified polyacrylate foam material of this embodiment is synthesized from the following raw materials in parts by weight:

[0037] 97 parts by weight of acrylate monomer, 5 parts by weight of silane coupling agent, 5 parts by weight of hydroxyl-terminated silicone oil, 2 parts by weight of boric acid, and 0.1 part by weight of initiator.

[0038] Wherein, the acrylate monomer is methyl methacrylate; the silane coupling agent is vinyltrimethoxysilane; and the initiator is azobisisobutyronitrile.

[0039] The preparation method of the polyborosiloxane-modified polyacrylate foam material described in this embodiment, the synthetic route is as follows:

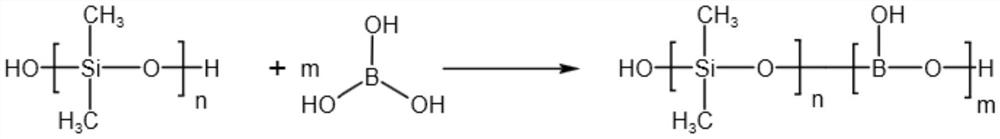

[0040] (1) Get hydroxyl-terminated silicone oil and boric acid to react to obtain polyborosiloxane; the reaction formula is as follows:

[0041]

[0042] Wherein, the ratio of m to n is (1-10):(1-5).

[0043] (2) Get acrylate monomer, silane coupling agent, initiator, react to obtain acrylate prep...

Embodiment 2

[0056] The polyborosiloxane-modified polyacrylate foam material of this embodiment is synthesized from the following raw materials in parts by weight:

[0057] 99 parts by weight of acrylate monomer, 3 parts by weight of silane coupling agent, 2 parts by weight of hydroxyl-terminated silicone oil, 1 part by weight of boric acid, and 0.1 part by weight of initiator.

[0058] Wherein, the acrylate monomer is methyl acrylate; the silane coupling agent is vinyltriethoxysilane; and the initiator is dibenzoyl peroxide.

[0059] The preparation method of the polyborosiloxane modified polyacrylate foam material described in this embodiment specifically comprises the following steps:

[0060] (1) Take hydroxyl-terminated silicone oil and boric acid, dissolve the hydroxyl-terminated silicone oil and boric acid in xylene solvent, and stir and react for 3 hours at 150° C. to obtain polyborosiloxane;

[0061] (2) Take acrylate monomer, silane coupling agent, and initiator, and dissolve th...

Embodiment 3

[0065] The polyborosiloxane-modified polyacrylate foam material of this embodiment is synthesized from the following raw materials in parts by weight:

[0066] 95 parts by weight of acrylate monomer, 1 part by weight of silane coupling agent, 8 parts by weight of hydroxyl-terminated silicone oil, 4 parts by weight of boric acid, and 0.1 part by weight of initiator.

[0067] Wherein, the acrylate monomer is formed by mixing butyl acrylate, glycidyl acrylate, and isobornyl acrylate in a weight ratio of 1:1:1; the silane coupling agent is vinyltrimethoxysilane; Described initiator is dibenzoyl peroxide.

[0068] The preparation method of the polyborosiloxane modified polyacrylate foam material described in this embodiment specifically comprises the following steps:

[0069] (1) Take hydroxyl-terminated silicone oil and boric acid, dissolve the hydroxyl-terminated silicone oil and boric acid in xylene solvent, and stir and react for 1 hour at 120°C to obtain polyborosiloxane;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com