Preparation method and application of brevibacillus laterosporus and spore antibacterial peptide-chitosan-gelatin composite preservative film

A Brevibacillus, antimicrobial peptide technology, applied in the directions of microorganism-based methods, botanical equipment and methods, biochemical equipment and methods, etc., can solve the problems of human health hazards, human health hazards, decline, etc., and achieve the suppression of food sources. Harmful microorganisms, safe bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

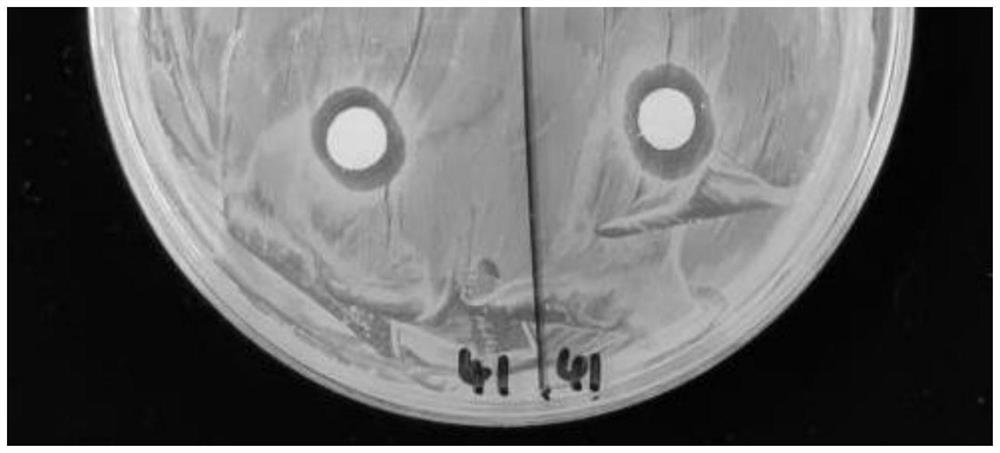

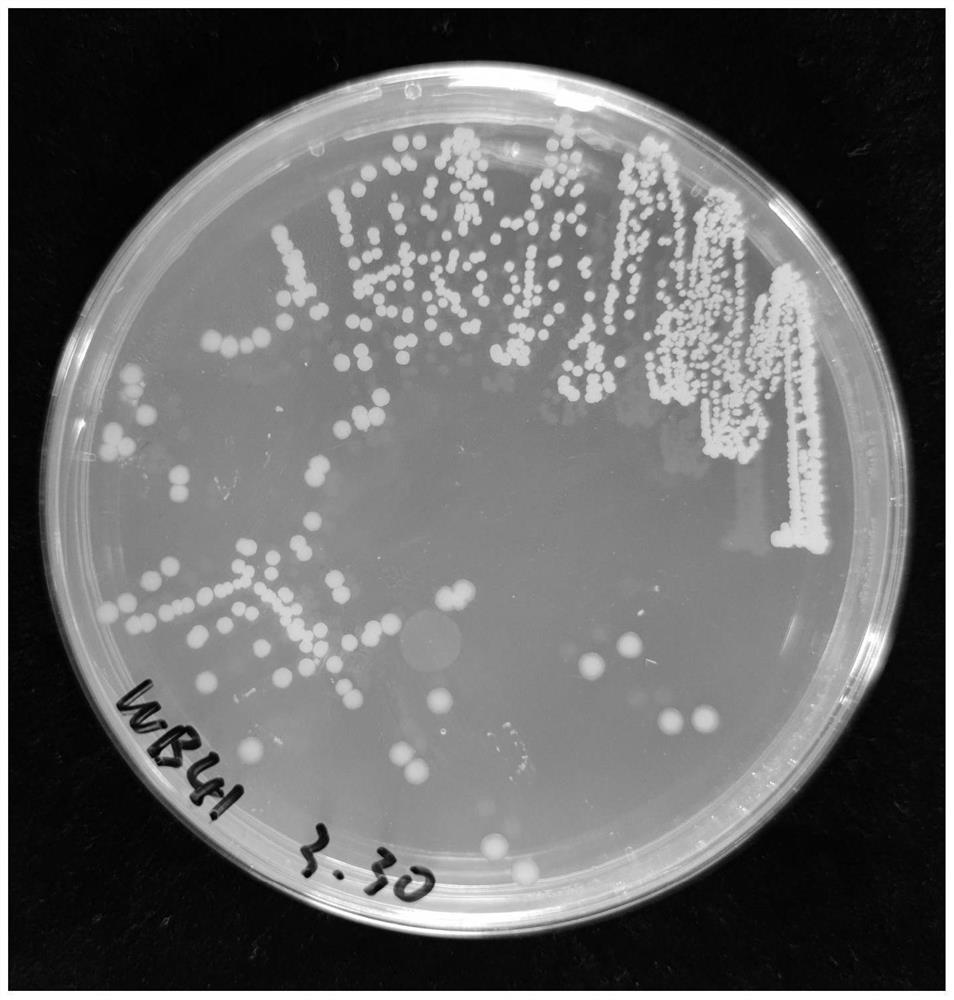

Image

Examples

Embodiment 1

[0086] A preparation method of spore antimicrobial peptide-chitosan-gelatin composite fresh-keeping film, the steps are as follows:

[0087] (1) Solution preparation

[0088] ⑤5% chitosan solution: Add chitosan to 1% acetic acid solution at a mass ratio of 5%, and stir magnetically at 40°C for 40-60min until a uniform viscous solution is formed.

[0089] ⑥ 0.75% gelatin solution: Add gelatin to deionized water at a mass ratio of 0.75%, and stir magnetically at 40°C until the gelatin is completely dissolved.

[0090] (2) Preparation of Antimicrobial Peptide Crude Extract

[0091]⑤ Inoculation of Brevibacillus spp. fermentation B07-2: inoculate the activated antagonistic Bacillus spp. at an inoculum amount of 1% into sterilized NB medium, and culture at 30° C. and 200 rpm for 72 hours.

[0092] ⑥ Rough extraction of antimicrobial peptides: adjust the pH of the fermentation broth to 3, and add 2% (mass ratio) NaCl after sterilizing at 121° C. for 20 minutes. Add activated carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com