Tremella-shaped carbon-coated nano-silver material as well as preparation method and application thereof

A carbon-coated and nano-silver technology is applied in the field of tremella-shaped carbon-coated nano-silver materials and the preparation thereof, which can solve the problems that a specific composite structure is difficult to realize, and achieve the effects of large specific surface area and high porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

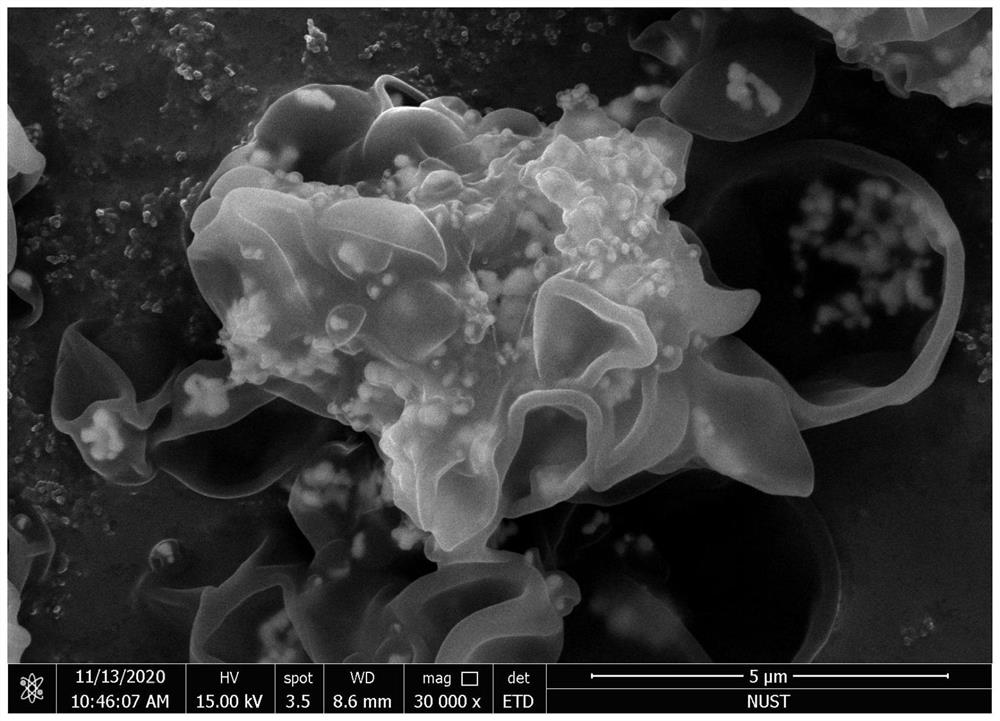

[0034] A tremella-shaped carbon-coated nano-silver material, the preparation method of which is as follows:

[0035] Under light-shielding conditions, add 20 mL of silver nitrate solution with a concentration of 0.01 mol / L into 20 mL of sucrose solution with a concentration of 0.5 mol / L while stirring, and add 5 mL of trioctylamine dropwise while stirring in the above-mentioned mixed solution, Put it into an ultrasonic cleaner for ultrasonic dispersion for 15 minutes to form a milky white solution. Wherein, the molar ratio of sucrose to silver nitrate is 50:1.

[0036] Transfer the milky white solution above to a 50mL stainless steel reaction kettle. The outer layer of the reaction kettle is stainless steel, and the inner layer is polytetrafluoroethylene. Hydrothermal reaction in the box for 18 hours, after cooling to room temperature, repeated alternate centrifugation with deionized water and absolute ethanol, and vacuum drying to obtain tremella-shaped carbon-coated nano-si...

Embodiment 2

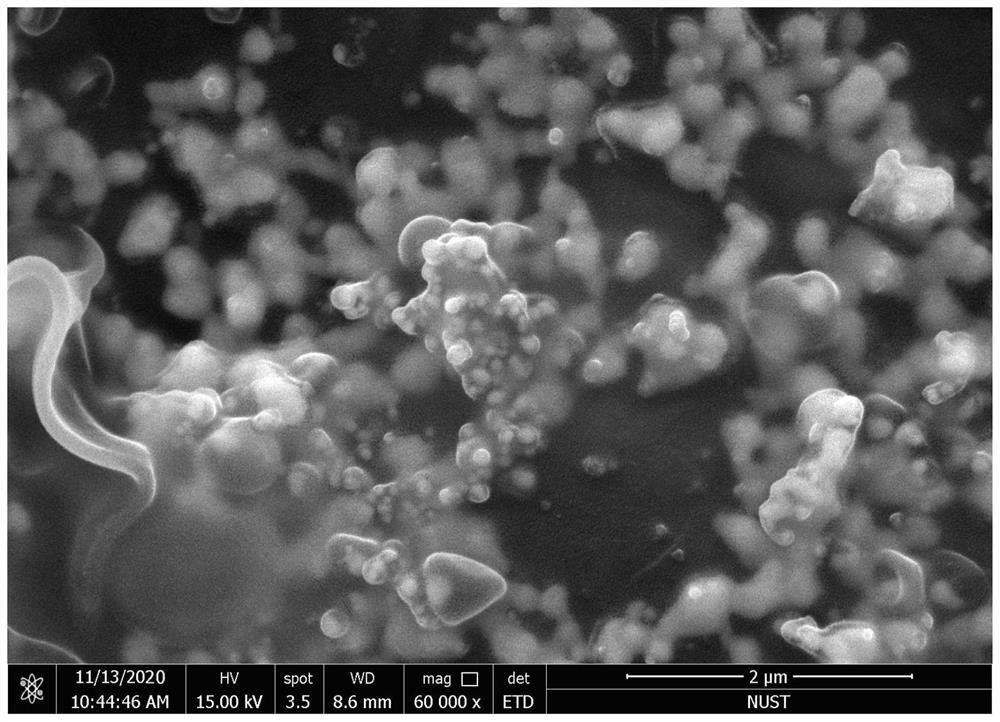

[0039] A tremella-shaped carbon-coated nano-silver material, its preparation method is basically the same as that of Example 1, the difference is: the trioctylamine added dropwise is 3mL; in a stainless steel reactor, react in a blast drying oven at 150°C 18h.

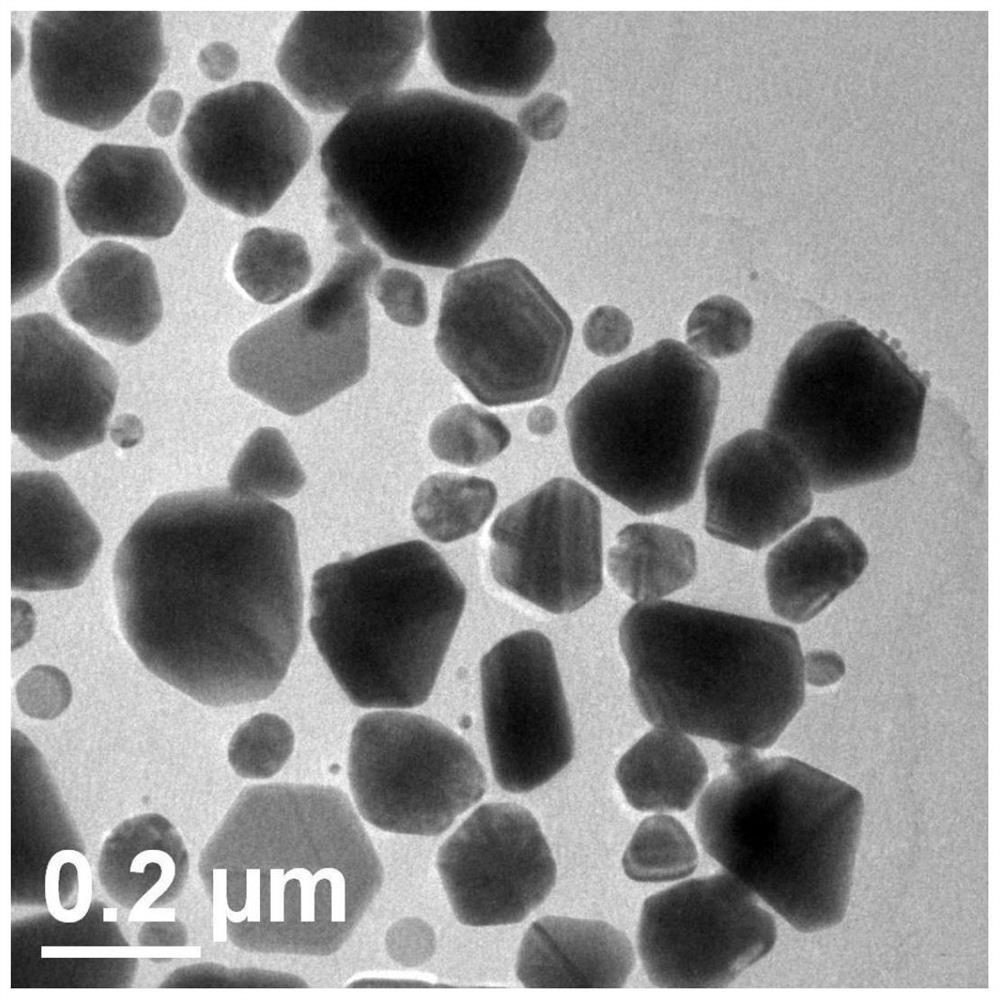

[0040] Such as image 3Shown is the partial transmission electron microscope collection of tremella-shaped carbon-coated nano-silver material prepared in Example 2 of the present invention. It is clearly observed from the picture that the crystallinity and dispersibility of the nano-silver particles are good, and the shapes are mostly circular and six-dimensional. Polygonal, with a size of 100-300nm.

[0041] Such as Figure 4 Shown, for the tremella-shaped carbon-coated nano-silver material prepared in Example 2 of the present invention, the structural characterization Raman spectrum and its corresponding Gaussian fitting spectrum, at 1360cm -1 and 1580cm -1 There are two broad peaks nearby, 1360cm -1 The nearby ...

Embodiment 3

[0043] A tremella-shaped carbon-coated nano-silver material, its preparation method is basically the same as that of Example 1, the difference is that the concentration of the sucrose solution is 0.1mol / L, and the molar ratio of sucrose to silver nitrate is 10:1; Trioctylamine is 3 mL.

[0044] Such as Figure 5 As shown, it is the X-ray diffraction spectrum of the Tremella-shaped carbon-coated nano-silver material prepared in Example 3 of the present invention. It is clearly shown in the figure that there is an obvious wrapping peak at a 2θ value of about 24°, corresponding to the hydrothermal carbon of the material. There are four sharp diffraction peaks at 2θ values of 38.14°, 44.32°, 64.48° and 77.45°, corresponding to (111), (200), (220) and (311) crystal planes of silver (Silver -3C, JCPDS #04-0783), demonstrating the presence of silver.

[0045] Such as Image 6 As shown, it is the scanning electron microscope collection of the Tremella-shaped carbon-coated nano-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com