Method for producing dimethyl disulfide by methyl mercaptan vulcanization method

A technology of dimethyl disulfide and dimethyl trisulfide, which is applied in the chemical industry, can solve the problems of difficult recovery of mercaptan synthesis tail gas, backward production equipment technology, and large loss of effective components, so as to avoid the decline of catalyst activity, The effect of high utilization rate of effective components and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

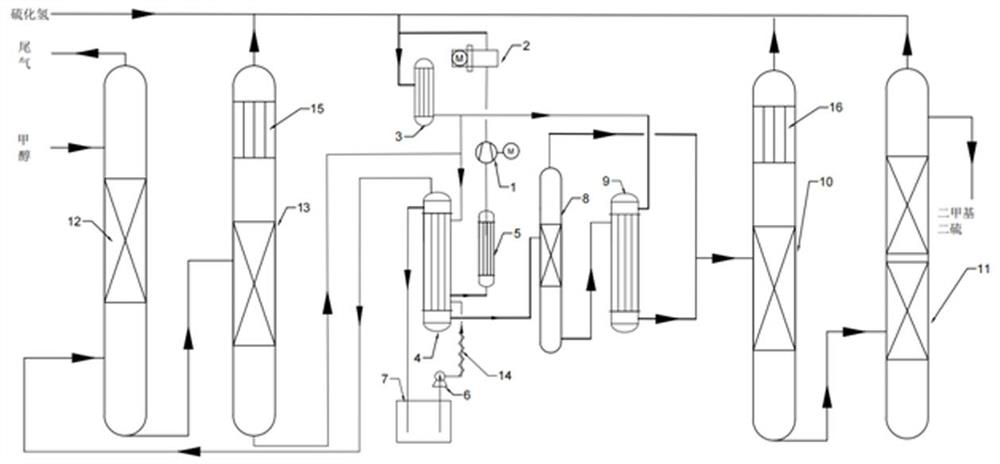

[0022] see figure 1 A method for producing dimethyl disulfide by a methyl mercaptan vulcanization method, comprising the following steps:

[0023] Step 1. Nitrogen enters the electric heater 2 for heating after being pressurized by the nitrogen blower 1. The heated nitrogen enters the steam heater 3 for heating again and then enters the mercaptan reactor 4 to heat it. After the nitrogen is discharged from the mercaptan reactor 4 Return to the nitrogen fan 1 after being cooled by the nitrogen water cooler 5, and the nitrogen heating system is stopped after circulating the nitrogen to the mercaptan reactor 4 to 180°C;

[0024] Step 2. Use the pipeline electric heater 14 to preheat the molten salt pipeline to 180°C to avoid damage to pipeline expansion caused by excessive heating of the pipeline, start the molten salt pump 6, and the molten salt enters the mercaptan reactor 4 from the molten salt tank 7 Continue heating it, the molten salt returns to the molten salt tank 7 after...

Embodiment 2

[0029] see figure 1 A method for producing dimethyl disulfide by a methyl mercaptan vulcanization method, comprising the following steps:

[0030] Step 1. Nitrogen enters the electric heater 2 for heating after being pressurized by the nitrogen blower 1. The heated nitrogen enters the steam heater 3 for heating again and then enters the mercaptan reactor 4 to heat it. After the nitrogen is discharged from the mercaptan reactor 4 Return to the nitrogen blower 1 after being cooled by the nitrogen water cooler 5, and the nitrogen circulates the mercaptan reactor 4 to heat up to 200°C, and stops the nitrogen heating system;

[0031] Step 2. Preheat the molten salt pipeline to 200°C with the pipeline electric heater 14, start the molten salt pump 6, and the molten salt enters the mercaptan reactor 4 from the molten salt tank 7 to continue heating it, and the molten salt reacts from the mercaptan Return to the molten salt tank 7 after the reactor 4 comes out, and the molten salt ci...

Embodiment 3

[0036] see figure 1 A method for producing dimethyl disulfide by a methyl mercaptan vulcanization method, comprising the following steps:

[0037] Step 1. Nitrogen enters the electric heater 2 for heating after being pressurized by the nitrogen blower 1. The heated nitrogen enters the steam heater 3 for heating again and then enters the mercaptan reactor 4 to heat it. After the nitrogen is discharged from the mercaptan reactor 4 Return to the nitrogen fan 1 after being cooled by the nitrogen water cooler 5, and then stop the nitrogen heating system after circulating the nitrogen to the mercaptan reactor 4 and raising the temperature to 220°C;

[0038] Step 2. Preheat the molten salt pipeline to 220°C with the pipeline electric heater 14, start the molten salt pump 6, and the molten salt enters the mercaptan reactor 4 from the molten salt tank 7 to continue heating it, and the molten salt reacts from the mercaptan Return to the molten salt tank 7 after the reactor 4 comes out,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com