Preparation method of xanthate collecting agent

A technology of xanthates and xanthates, which is applied in the field of preparation of xanthate collectors, can solve problems such as difficult separation of xanthates, unfavorable dispersion or dissolution, and strong pungent odor. Achieve outstanding environmental benefits, no irritating odor, and weak water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

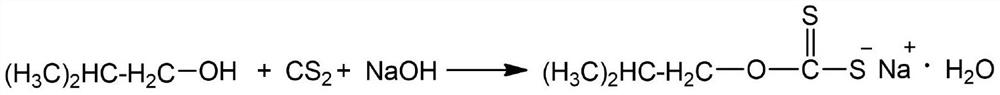

[0047] The preparation of embodiment 1 sodium isobutyl xanthate (I)

[0048] Add 43 parts of diethyl ether with a purity of 99% into the reactor, start stirring, add 8.4 parts of granular sodium hydroxide with a purity of 96%, then add 14.97 parts of isobutanol with a purity of 99% dropwise at 0°C to 10°C, and complete the addition After that, react at 10°C for 30 min. Then slowly add 15.69 parts of carbon disulfide dropwise at 5°C to 10°C, after the addition, stir and react at 10°C for 2 hours, and then react at 18°C for 2 hours. After the reaction was completed, the reaction mixture was distilled to remove ether to obtain a product of sodium isobutyl xanthate monohydrate with a purity of 99.5%. The product had a very light smell and no stimulation, and the yield based on isobutanol was 99.6%. The reaction equation of synthetic sodium isobutyl xanthate is as follows:

[0049]

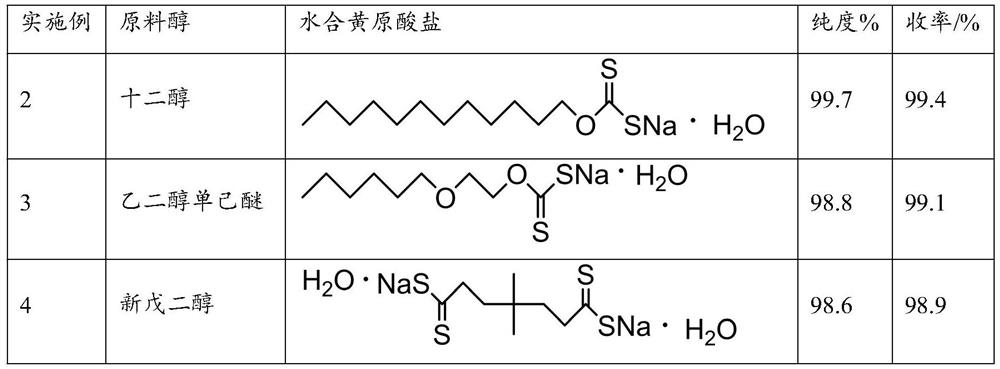

Embodiment 2 10

[0050] The preparation of embodiment 2 sodium dodecyl xanthate

[0051] Change 14.97 parts of 99% isobutanol into 37.26 parts of 99% dodecanol with a purity of 99% in Example 1, change 43 parts of diethyl ether into 64 parts of diethyl ether, and stir and react at 12° C. for 2 hours after adding carbon disulfide. Reaction at 24°C for another 3h. Other conditions were the same as in Example 1, and the sodium dodecyl xanthate product was obtained, which had a very light smell and was non-irritating. The yield based on lauryl alcohol was 99.4%, and the purity was shown in Table 1.

Embodiment 3

[0052] The preparation of embodiment 3 hexyloxyethyl xanthate sodium

[0053] Change 14.97 parts of 99% isobutanol into 29.84 parts of ethylene glycol monohexyl ether with a purity of 98% in Example 1, change 43 parts of diethyl ether into 52 parts of diethyl ether, and stir and react at 12°C after adding carbon disulfide After 2 hours, react at 24°C for another 2h. Other conditions were the same as in Example 1, and the sodium hexyloxyethyl xanthate product was obtained, which had a very light smell and was non-irritating. The yield based on ethylene glycol monohexyl ether was 99.1%, and the purity was shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com