Preparation method of two-phase flexible PDMS composite material and wearable pressure sensor

A pressure sensor, composite material technology, applied in chemical instruments and methods, fluid pressure measurement by changing ohmic resistance, instruments, etc., can solve the problem of difficult to obtain high sensitivity and stability of the sensor performance, porous sponge shedding, sensor conductive material Difficult to penetrate and other problems, to achieve the effect of reducing entanglement and agglomeration, improving electrical conductivity, high sensitivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The flexible matrix material selected in this embodiment is polydimethylsiloxane PDMS, PDMS is a typical silicone rubber material, has a silicon-oxygen bond (Si-O) with a helical structure, and all side groups are methyl groups, PDMS silicon oxide The bonds have large bond angles, so they are prone to rotation, resulting in good flexibility. PDMS is a thermosetting material, which is divided into a main body and a curing agent. The main body is a siloxane oligomer, and the curing agent is a siloxane crosslinking agent. The two components can be crosslinked under heating conditions. Since there are multiple reaction sites between the main body of PDMS and the curing agent, it can be cured and formed under the action of heat after being fully mixed.

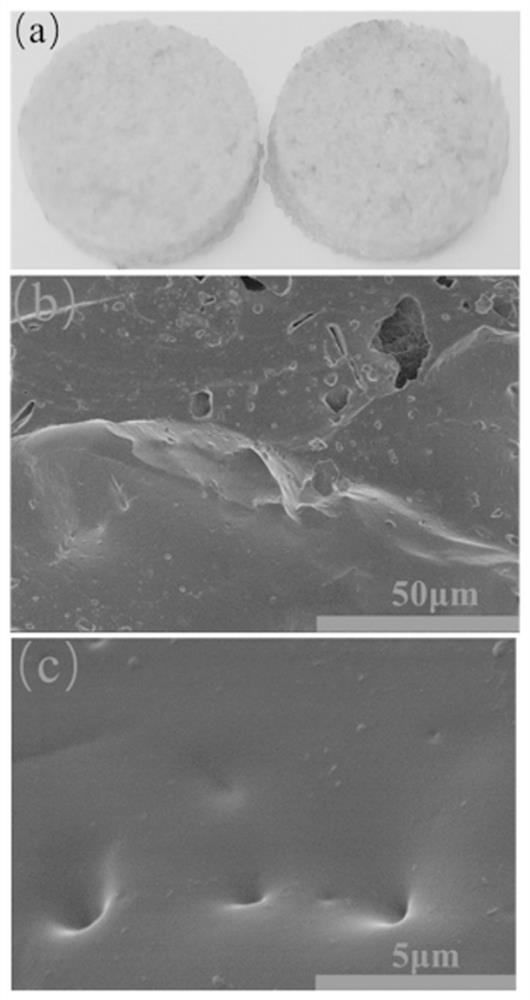

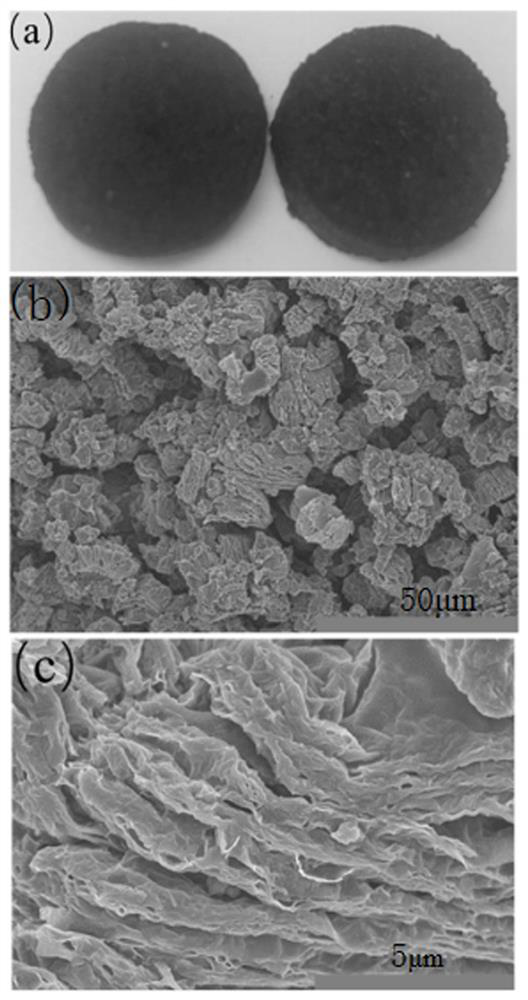

[0039] In this example, PDMS is used instead of water, graphene rGO and sugar particles are fully mixed, and PDMS sponge and curing agent are added, and after fully stirring, the tablet is pressed using a tablet press, and t...

Embodiment 2

[0053] In this embodiment, the preparation method of the two-phase flexible PDMS composite material as in the first embodiment is adopted, and a flexible resistive pressure sensor is formed. The flexible resistive pressure sensor is formed by connecting two-phase flexible PDMS composite materials and wires. Specifically, the prepared rGO / PDMS conductive sponge is placed on the work table, and the upper and lower sides of the conductive sponge are covered with conductive tape. The surface and lead out the tested electrodes to obtain a flexible resistive pressure sensor.

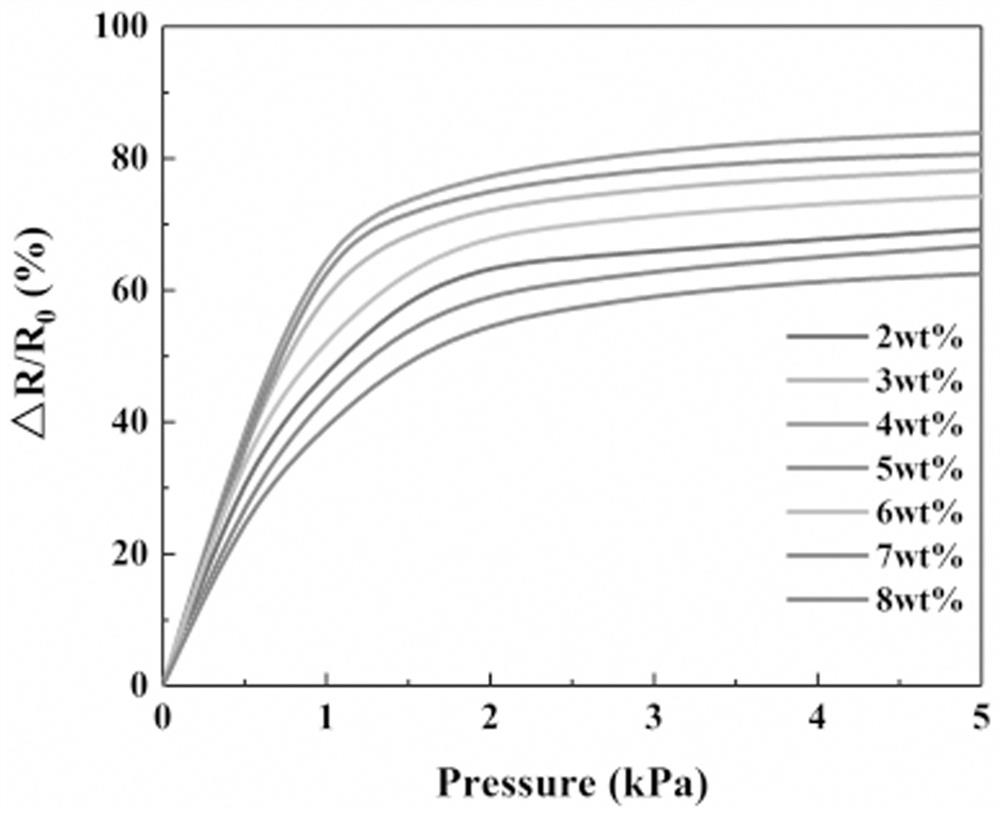

[0054] Sensitivity refers to the sensitivity of the sensor to the stimulus when it is stimulated by external pressure, which is mainly judged by the slope of the △R / R0 curve. In this embodiment, the sensitivity of the sensor is tested, and the influence of different graphene rGO concentrations on the sensitivity of the flexible resistive pressure sensor is compared. The sensitivity test method of the sensor i...

Embodiment 3

[0064] From the first and second examples, it can be obtained that when the doping concentration of graphene is 4wt%, the sensitivity of the flexible resistive pressure sensor is the highest. In this embodiment, weights and an electrochemical workstation are used to test the response time of the flexible pressure sensor, the sensor and the electrochemical workstation are used to form a series circuit, and then the i-t test program is selected in the program of the electrochemical workstation, and the weight is placed on the flexible pressure sensor. On the pressure sensor, record the response time of the flexible pressure sensor to the weight.

[0065] In this embodiment, the rGO / PDMS conductive sponge with the highest sensitivity is selected for the responsiveness and recovery test, and the response time and recovery time when the pressure is 1kPa, 2.5kPa and 5kPa are tested, and the test results are as follows Figure 5 shown.

[0066] When the applied pressure is 1kPa, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com