Gas diffusion layer for electrochemical reduction of carbon dioxide and preparation method of gas diffusion layer

A gas diffusion layer, carbon dioxide technology, applied in electrodes, electrolysis components, electrolysis process and other directions, can solve the problems of unfavorable gaseous carbon dioxide transportation, low conversion efficiency, low carbon dioxide reduction current density, etc., and achieves low production cost, simple preparation process, The effect of improving gas diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

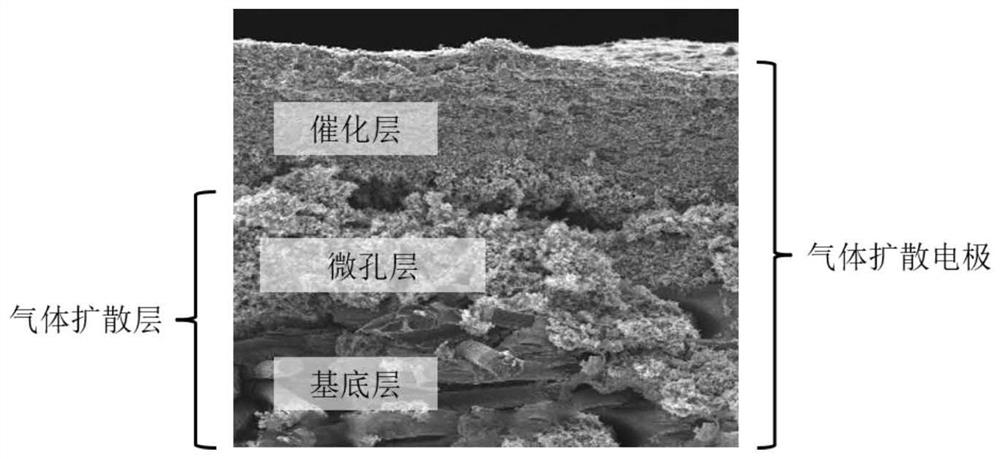

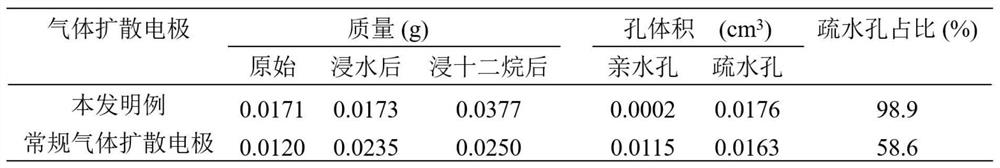

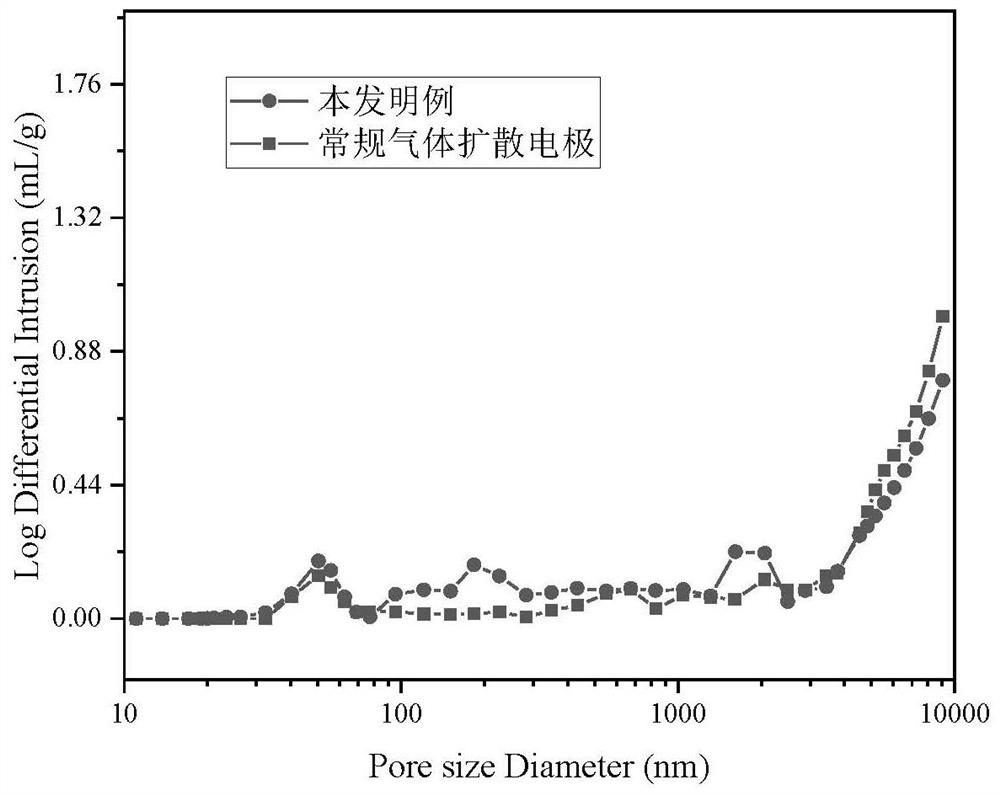

Image

Examples

preparation example Construction

[0037] The preparation method of the aforementioned gas diffusion layer comprises the following steps:

[0038] 1) Immerse the base layer in a certain concentration of hydrophobic agent emulsion for 1-60s, then take it out and dry it at 50-80°C to constant weight;

[0039] 2) Repeat the above process until the base layer and hydrophobic agent reach a certain mass ratio, the mass ratio range is 1:0.05~1:4;

[0040] 3) Mix the conductive material, the hydrophobic agent emulsion and the dispersant, stir fully to make the conductive material and the hydrophobic agent fully contact, and obtain the microporous layer slurry; the mass ratio of the conductive material to the hydrophobic agent is 1:0.05~1:2 The dispersant is a mixture of one or more of dehydrated alcohol, isopropanol, ultrapure water, etc. mixed in any proportion;

[0041]4) Deposit the conductive material / hydrophobic agent mixed slurry obtained in step 3) onto one side of the base layer treated with the hydrophobic ag...

Embodiment 1

[0046] This embodiment relates to a gas diffusion layer for electrolytic electrochemical reduction of carbon dioxide and its preparation method, the steps are as follows:

[0047] 1) Soak the WOS1009 carbon cloth produced by Carbon Energy CeTech Company in 5wt% polytetrafluoroethylene emulsion for 30 seconds, take it out and vacuum dry it to a constant weight in a drying oven at 60°C. Repeat the above steps until the weight difference between the impregnated and dried carbon cloth accounts for 30wt% of the total weight of the impregnated and dried carbon cloth.

[0048] 2) Mix 5g of Vulcan XC-72 conductive carbon black, 25g of 5wt% polytetrafluoroethylene emulsion (containing 1.25g of polytetrafluoroethylene) and 10g of absolute ethanol, stir well to make it evenly mixed.

[0049] 3) Coating the emulsion in 2) by screen printing on one surface of the 6×11 cm carbon cloth obtained in 1) after the hydrophobic treatment, to obtain a diffusion electrode layer precursor.

[0050] ...

Embodiment 2

[0055] A gas diffusion layer for electrolytic electrochemical reduction of carbon dioxide and a preparation method thereof, the steps are as follows:

[0056] 1) Soak Toray TGP-H-060 carbon paper produced by Toray Corporation in Japan in 5wt% polytetrafluoroethylene emulsion for 30 seconds, take it out and vacuum-dry it in a drying oven at 60°C to a constant weight. Repeat the above steps until the weight difference between the impregnated and dried carbon cloth accounts for 10wt% of the total weight of the impregnated and dried carbon cloth.

[0057] 2) 1g Vulcan XC-72R conductive carbon black, 0.42g 60wt% polytetrafluoroethylene emulsion (containing 0.25g polytetrafluoroethylene), 0.1g ultrapure water and 0.2g isopropanol were ultrasonically treated for 30 minutes.

[0058] 3) Spray-coat the uniform emulsion obtained in 2) on one side of Toray TGP-H-060 carbon paper, and the loading amount of conductive carbon black in the microporous layer is 1 mg cm -2 , to obtain the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com